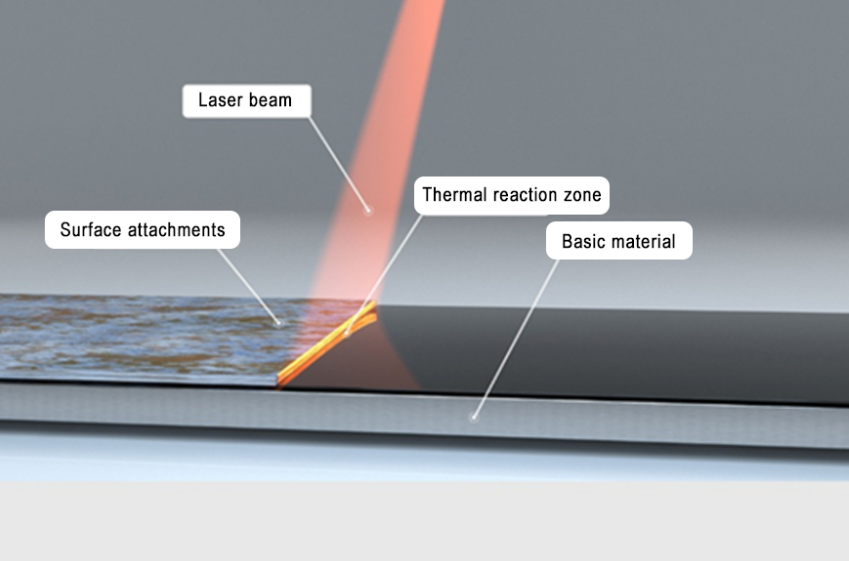

Laser cleaning is an advanced surface treatment technology that uses high-energy laser beams to instantly evaporate and peel off surface attachments (contaminants, rust, coatings, etc.). Compared with traditional mechanical, chemical and ultrasonic cleaning methods, laser cleaning has significant advantages such as precision, efficiency and controllability, which can effectively improve the surface quality of components and extend their service life. With the continuous improvement of surface quality requirements in industrial development, traditional cleaning technologies are gradually unable to meet the demands. Laser cleaning, with its non-contact, non-destructive and environmentally friendly characteristics, has become a key technology for enhancing component performance in modern manufacturing.

Schematic diagram of laser cleaning

The application of laser cleaning in the industrial field

With the popularization of the concepts of intelligent manufacturing and green manufacturing, laser cleaning technology is entering a period of rapid development, and its application prospects in the industrial field are broad. This technology, with its advantages of being environmentally friendly, efficient and precise, is gradually replacing traditional cleaning methods and has been widely applied in key fields such as high-end equipment manufacturing, precision electronics and aerospace. Meanwhile, the continuous emergence of new materials and new processes will further expand the application boundaries of laser cleaning. Below, we will introduce the main applications of laser cleaning in industry through different materials.

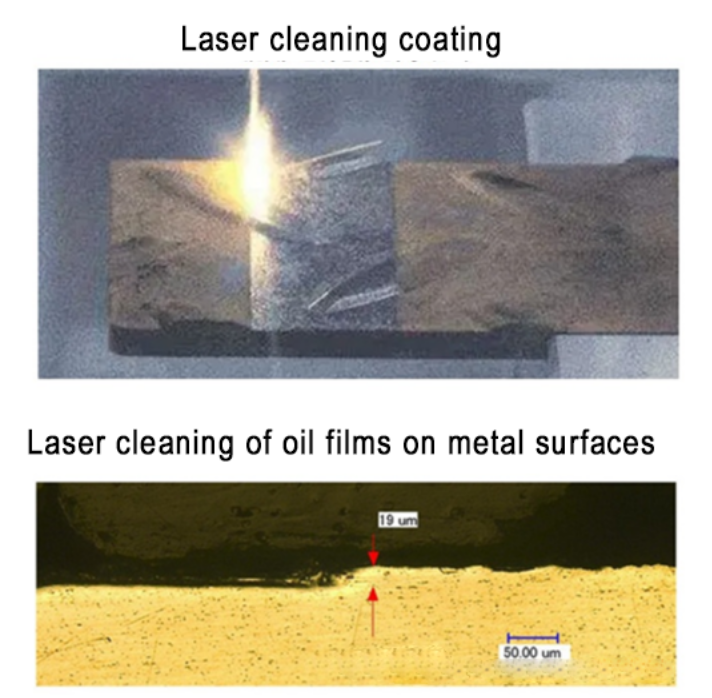

Laser cleaning is mainly used in the field of metal materials to remove oil films, coatings, paints and oxide layers. For instance, on the surfaces of carbon steel, stainless steel and aluminum alloy, lasers can efficiently remove oil stains and lubricants without damaging the substrate. For aircraft skins, automotive parts, etc., lasers can selectively peel off old coatings or paints and provide better adhesion for new coatings. In addition, laser cleaning can effectively remove the oxide layer on the surface of metals (such as carbon steel and titanium alloys), improve the quality of welding and painting, and in some cases, its effect is better than that of traditional mechanical polishing.

Schematic diagram related to laser cleaning of metal materials

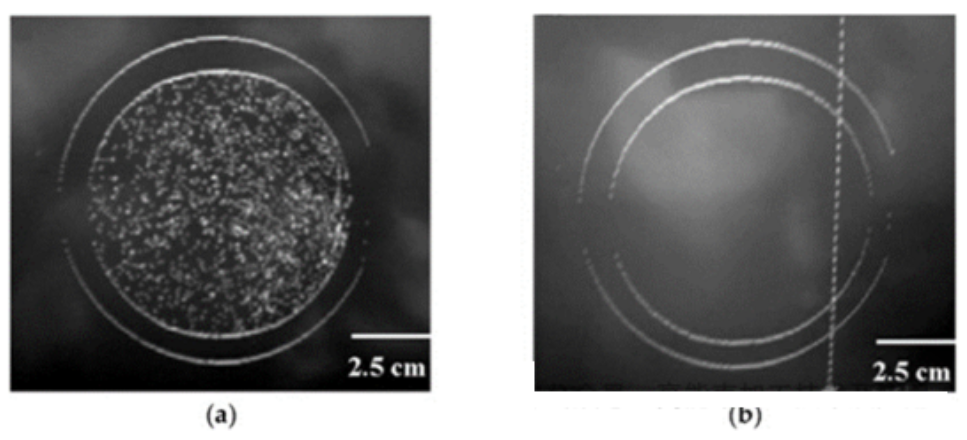

Among non-metallic materials, laser cleaning is applicable to insulating materials (glass, ceramics, silicone rubber), stone and composite materials. For instance, lasers can non-destructively clean insulating materials in power equipment or remove pigment graffiti and biofilms from the surface of granite. For carbon fiber reinforced plastic (CFRP), lasers can precisely peel off the epoxy resin layer, enhance the bonding strength, and prevent fiber damage caused by mechanical grinding. Figure 3 shows the macroscopic comparison of CFRP before and after laser cleaning.

Comparison before and after laser cleaning of CFRP

Semiconductor manufacturing has extremely high requirements for cleanliness. Laser cleaning can efficiently remove nanoscale particles (such as alumina and copper particles) on the surface of silicon wafers, ensuring high-precision processing of integrated circuits. In addition, lasers are also used for cleaning photomask, avoiding substrate damage through the plasma shock wave mechanism, and are suitable for advanced technologies such as extreme ultraviolet lithography.

Comparison picture of laser cleaning of silicon wafer surface

Laser cleaning, with its high precision, environmental friendliness and wide applicability, has shown great potential in the fields of metals, non-metals, semiconductors and special industries. In the future, this technology will achieve breakthrough progress in three major directions: high-end manufacturing, green environmental protection and intelligent application. In the high-end manufacturing sector, laser cleaning will be deeply applied to key process links such as the maintenance of aerospace precision components, the pre-treatment of new energy vehicle battery welding, and the cleaning of semiconductor wafers, promoting a comprehensive improvement in manufacturing accuracy and efficiency. In terms of environmental protection, its pollution-free feature will accelerate the replacement of traditional chemical cleaning processes, especially in fields with strict environmental requirements such as nuclear waste treatment and maintenance of petrochemical equipment. In terms of intelligent development, through the integration with AI visual recognition and industrial robot technology, laser cleaning will achieve adaptive parameter adjustment and autonomous operation under complex working conditions, significantly expanding its application scenarios.

Post time: Jul-10-2025