In the bustling landscape of modern industrial production, China has emerged as a powerhouse in manufacturing advanced laser welding solutions. Chinese laser welding machine factories play a pivotal role, supplying a wide range of high – quality equipment globally. Among the various offerings, China handheld laser welding machines have gained significant popularity for their flexibility and ease of use, while China laser welding machine suppliers ensure a steady supply of cutting – edge technology to meet diverse industrial needs.

Copper, standing as the second most – utilized non – ferrous metal worldwide, just behind aluminum, has extensive applications. Among its types, red copper is widely used in construction, electrical systems, and mechanical manufacturing. Its remarkable electrical and thermal conductivity, along with excellent malleability, enables seamless hot and cold pressing processes. As industrial demands grow, the application scope of red copper continues to expand.

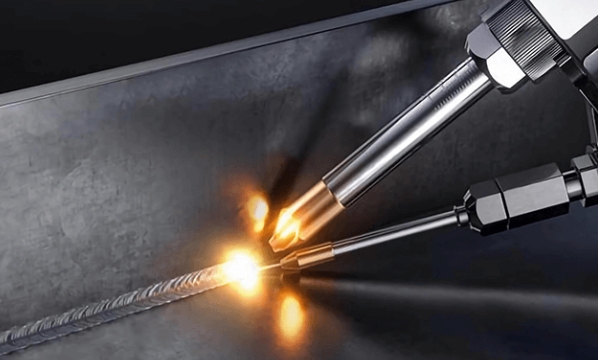

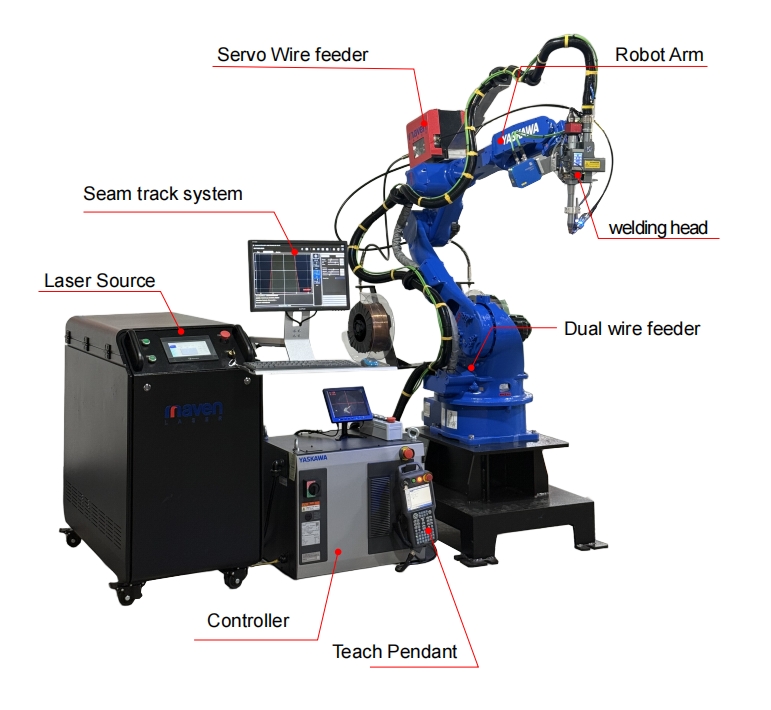

Laser welding, with its high – energy density, minimal molten metal volume, and narrow heat – affected zone, offers top – notch welding quality and efficient production. China portable laser welding machine manufacturers are at the forefront, producing devices that can greatly enhance productivity when applied to copper welding, attracting industries looking for convenient and powerful welding solutions. However, the welding process still presents difficulties. Copper, as a highly reflective material, has limited absorption of fiber lasers, which complicates the operation and increases the requirements for laser light sources.

During copper welding, several typical problems often occur. The high thermal conductivity of red copper causes rapid heat dissipation, resulting in a broad heat – affected area and making proper material fusion challenging. Additionally, red copper’s large linear expansion coefficient means that improper clamping forces during welding can lead to material deformation. Porosity is another critical issue, especially in deep – penetration welding, caused by hydrogen dissolution and redox reactions.

Chinese laser welding machine suppliers and manufacturers are constantly researching and developing solutions. At ambient temperature, red copper has a low absorption rate of around 5% for infrared lasers, but heating it close to the melting point shows promise for improving the welding process. With the continuous innovation of China handheld laser welding machines and other advanced equipment from Chinese laser welding machine factories, the future of copper laser welding looks increasingly bright, as these products are not only highly functional but also well – positioned for high visibility on platforms like Google, thanks to their quality and relevance to industrial search queries.

Post time: May-22-2025