Laser Beam Welding, with its high speed, high precision and non-contact characteristics, is widely applied in fields such as automobiles, aerospace, and electronic devices, especially showing unique advantages in the connection of dissimilar materials. However, the solidification cracks (Solidification Cracking) generated during the welding process are one of the key defects restricting its industrial application. These cracks usually occur at the end of solidification in the fusion zone (Fusion Zone), triggered by the combined effects of thermal stress, solidification shrinkage and the liquid film on the grain boundaries, significantly reducing the mechanical properties and fatigue life of the joint.

1.Formation mechanism

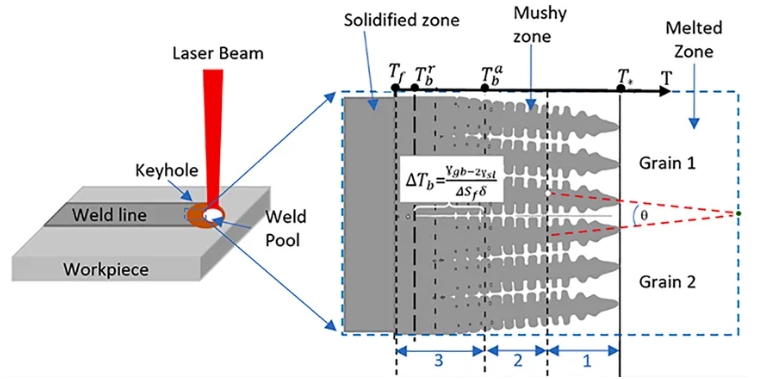

The core mechanism of solidification cracks lies in the residual liquid film at the grain boundaries at the end of solidification. During the solidification process, the molten pool is divided into three zones: the free liquid zone, the restricted liquid zone, and the solid zone, as shown in Figure 1. In the restricted liquid zone, the liquid flow is blocked and cannot compensate for the strain generated by solidification shrinkage, resulting in grain boundary separation. The ratio of grain boundary energy (γgb) to solid-liquid interface energy (γsl) determines the stability of the liquid film: if γgb < 2γsl, the liquid film is unstable and grain coalescence occurs; conversely, the liquid film is stable and crack initiation is prone to occur.

Furthermore, the formation of solidification cracks is also related to the metallurgical properties of the materials. Different materials have distinct solidification characteristics, such as the temperature range of solidification, the solidification shrinkage rate, and the distribution of alloy elements, etc. These characteristics influence the sensitivity of cracks. For instance, in materials containing a large amount of low-melting-point eutectic phases, the sensitivity of solidification cracks is higher because these eutectic phases are prone to form continuous liquid films during solidification, thereby intensifying the formation of cracks.

During the laser welding process, welding parameters such as laser power, welding speed, and spot size also have an impact on the formation of solidification cracks. These parameters affect the heat input and temperature gradient during the welding process, thereby altering the solidification structure and grain morphology. For instance, higher laser power and lower welding speed result in greater heat input and slower cooling rate, which promotes the growth of columnar crystals and increases the crack sensitivity. Conversely, lower laser power and higher welding speed lead to smaller heat input and faster cooling rate, facilitating the formation of equiaxed crystals and reducing the crack sensitivity.

2.Suppression measures

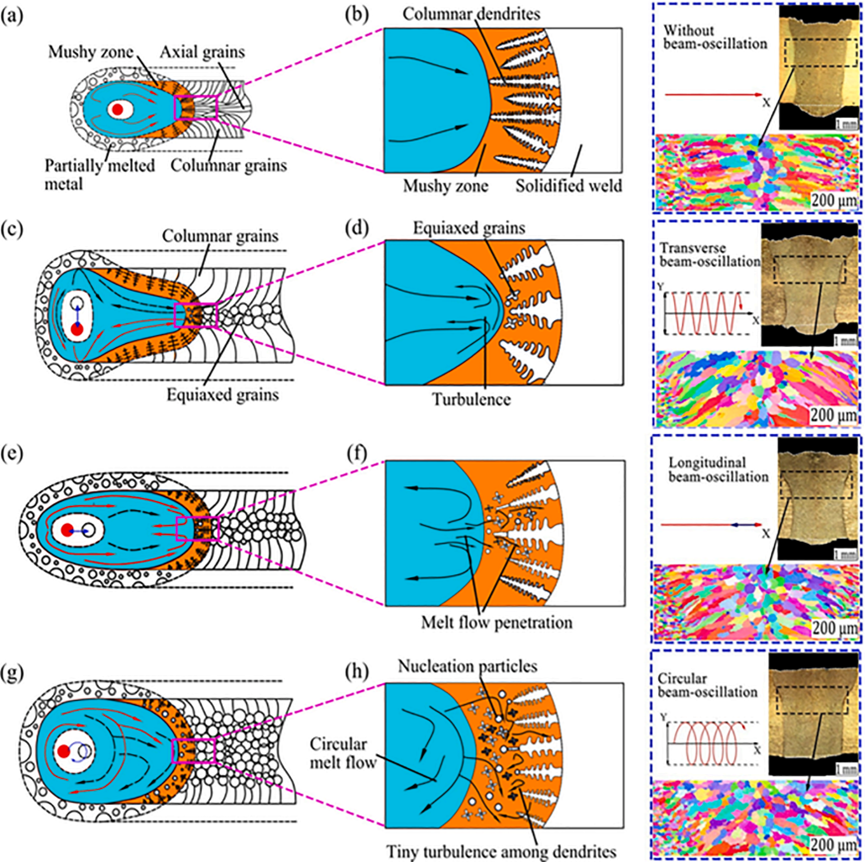

To effectively suppress the solidification cracks in laser welding, researchers have proposed various strategies, which mainly focus on controlling the grain structure, optimizing the welding parameters, and improving the material properties. By refining the grain structure, the number of grain boundaries can be increased, and the concentration of stress concentration can be reduced, thereby reducing the formation of cracks. Studies have shown that by using laser beam oscillation technology, columnar crystals can be transformed into fine equiaxed crystals without adding other materials. Laser beam oscillation can disperse laser energy, causing the molten pool to generate turbulence, thereby breaking the growth direction of columnar crystals and promoting the formation of equiaxed crystals, as shown in Figure 3. In addition, laser beam oscillation can also increase the width of the molten pool, reduce the temperature gradient, and prolong the solidification time of the molten pool, which is conducive to the diffusion of solutes and the replenishment of liquid films, thereby significantly reducing the sensitivity of solidification cracks.

Distribution of grain boundary liquid films under different pool shapes.

Schematic diagram of the welding molten pool, a, b) without oscillation, c, d) lateral oscillation, e, f) longitudinal oscillation, g, h) circumferential oscillation.

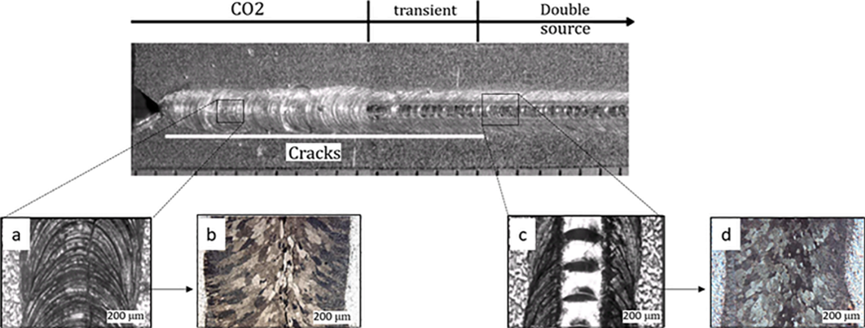

In addition to the laser beam oscillation technology, using dual laser sources is also one of the effective methods to suppress solidification cracks. Dual laser sources can achieve the transformation from columnar crystals to equiaxed crystals by optimizing the thermal cycle, thereby reducing grain size and strain concentration. For example, when using CO₂ laser as the main heat source and Nd:YAG pulsed laser as the auxiliary heat source, an optimized thermal cycle can be formed during welding, promoting the formation of equiaxed crystals and reducing the sensitivity of solidification cracks, as shown in Figure 4.

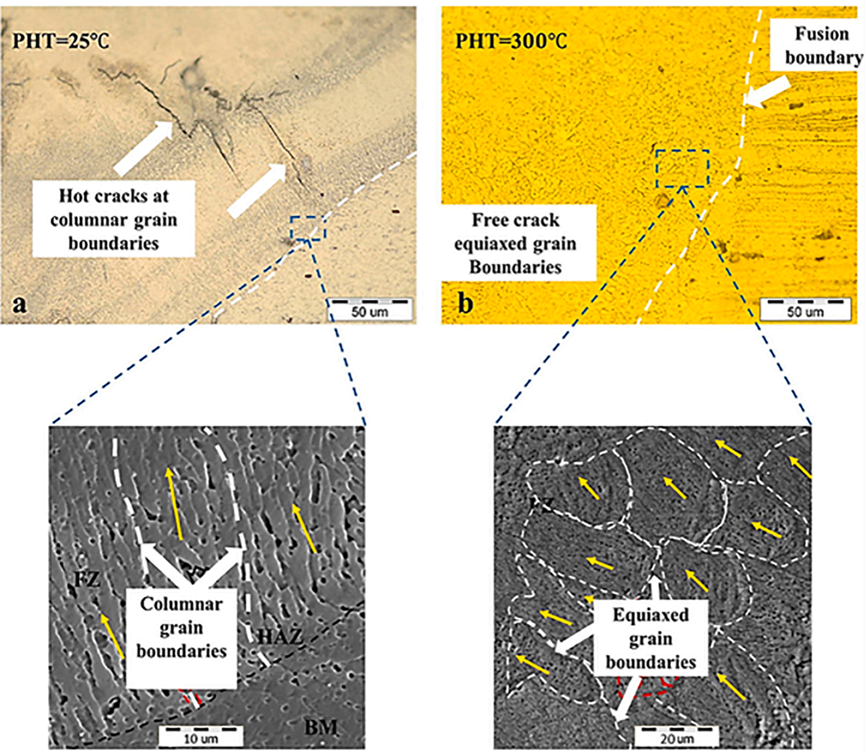

Optimizing welding parameters is also an important means to suppress solidification cracks. By adjusting parameters such as laser power, welding speed, and spot size, the heat input and temperature gradient during the welding process can be controlled, thereby influencing the solidification structure and grain morphology. Studies have shown that preheating treatment can reduce the cooling rate, promote the formation of equiaxed crystals, and thereby reduce the sensitivity of solidification cracks, as shown in Figure 5. In addition, methods such as using pulsed laser welding and increasing the welding speed can also achieve the transformation from columnar crystals to equiaxed crystals by changing the heat input and cooling rate, thereby reducing the sensitivity of cracks.

Figure 5. a) Unheated, b) 300°C preheated equiaxed grains.

When welding dissimilar materials with lasers, due to the significant differences in physical and chemical properties between the materials, brittle intermetallic compounds are prone to form, which are one of the main causes of solidification cracks. Therefore, adjusting laser parameters and settings to reduce the formation or quantity of intermetallic compounds is also an important strategy to suppress solidification cracks. For example, in the laser welding of copper-aluminum dissimilar materials, by controlling the offset of the laser beam and the welding speed, the mixing ratio of copper and aluminum in the molten pool can be reduced, thereby decreasing the formation of brittle intermetallic compounds and reducing the sensitivity of cracks. In addition, using filler materials can also improve the performance of the welded joint and reduce the formation of cracks. Filler materials can reduce the formation of intermetallic compounds by changing the composition and microstructure of the welded joint and improve the toughness of the welded joint.

Solidification cracks are one of the common defects in laser welding processes. Their formation mechanism is complex and involves the interaction of multiple factors such as heat, mechanics, and metallurgy. By deeply studying the formation mechanism of solidification cracks, theoretical basis can be provided for suppressing cracks. In recent years, researchers have proposed various strategies to suppress solidification cracks, which mainly focus on controlling grain structure, optimizing welding parameters, and improving material properties. Practice has proved that these strategies can effectively reduce the sensitivity of solidification cracks to a certain extent and improve the quality and reliability of laser welding. However, due to the complexity and diversity of the laser welding process, there are still some deficiencies in current research. For example, for the inhibition mechanisms of solidification cracks under different materials and welding conditions, further in-depth research is still needed.

Post time: Mar-20-2025