Understanding the Advantages of Fiber Laser Welding Machines for Modern Manufacturing

Table of Contents

- Advantages of Fiber Laser Welding Machines in Efficiency and Speed

- Key Technical Innovations Driving Fiber Laser Welding Technology

- Comparative Cost Analysis: Fiber Laser vs. Traditional Welding Methods

- Impact of Fiber Laser Welding on Material Versatility in Manufacturing

- Industry Case Studies: Fiber Laser Welding Success Stories and Metrics

- Future Trends: Advancements in Fiber Laser Technology for Manufacturing

- FAQS

- Conclusion

- Related Posts

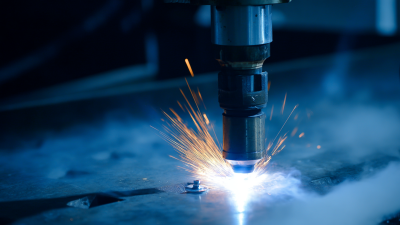

In recent years, the adoption of Fiber Laser Welding Machines has revolutionized the manufacturing sector, providing unparalleled precision and efficiency in metal joining processes. According to a report by Research and Markets, the global fiber laser market is projected to grow at a CAGR of over 10% through 2026, highlighting the increasing demand for advanced welding solutions. As a leading manufacturer of laser systems, Maven Laser Automation Co., Ltd. recognizes the transformative impact of fiber laser technology since its inception in 2008. With their innovative approach to laser case design and professional automation solutions, Maven Laser is at the forefront of this technological evolution, helping modern industries leverage the advantages of Fiber Laser Welding Machines for improved productivity and reduced operational costs.

This introduction sets the stage for a deeper exploration of the benefits these machines offer, from enhanced weld quality to greater versatility in diverse manufacturing applications.

Advantages of Fiber Laser Welding Machines in Efficiency and Speed

Fiber laser welding machines are revolutionizing modern manufacturing, particularly in terms of efficiency and speed. The ongoing advancements in laser technology are illustrated by the anticipated growth of the laser cutting machines market, which is projected to expand at a CAGR of 6.5% from 2025 to 2034, potentially reaching around $7.3 billion. This market growth reflects the increasing adoption of fiber laser solutions that enhance productivity and reduce operational costs.

Moreover, the fiber laser market itself is expected to surge to USD 12.8 billion, with a remarkable CAGR of 11.5% from 2025 to 2035. This growth is driven by the technology's inherent advantages, including higher precision, faster processing speeds, and lower energy consumption compared to traditional welding methods. As significant innovations in fiber laser machines continue to emerge, businesses that integrate these technologies can expect improved production efficiency and a stronger competitive edge in the market.

Key Technical Innovations Driving Fiber Laser Welding Technology

Fiber laser welding technology has seen significant advancements driven by innovative technical developments. These machines offer higher precision and efficiency in welding processes, making them increasingly desirable in modern manufacturing. The key innovations include improved laser beam quality, enhanced energy efficiency, and faster processing speeds. This allows manufacturers to achieve cleaner welds with less heat distortion, reducing the risk of material damage and ensuring product integrity.

Moreover, the application of high-power lasers in cutting, welding, and drilling has revolutionized various industries. The high energy density of fiber lasers permits deep penetration welding, allowing for thicker materials to be joined seamlessly. Recent trends in laser technology, such as automation and smart integration, also enhance operational efficiency and productivity. As companies explore these advancements, new startups are emerging, focusing on niche applications and tailored solutions that further push the boundaries of what fiber laser welding can achieve. The intersection of innovation and practical application in this field holds promising implications for the future of manufacturing.

Comparative Cost Analysis: Fiber Laser vs. Traditional Welding Methods

When evaluating the comparative costs of fiber laser welding machines versus traditional welding methods, several factors come into play. Initially, the purchase price of fiber laser welding machines can be higher than conventional machines. However, the long-term savings are compelling. Fiber lasers have lower operational costs due to reduced electricity consumption and minimal maintenance requirements. They also achieve higher speeds, leading to increased productivity, which translates into cost savings over time.

**Tips:** Consider the overall lifecycle cost instead of just the initial investment. Although traditional welding methods might seem less expensive upfront, the cumulative costs of labor, consumables, and downtime can make them more costly in the long run.

Furthermore, fiber laser technology allows for greater precision and finer welds, which can reduce material waste. When accounting for material costs, this precision can lead to significant savings. Evaluating these factors holistically helps manufacturers understand that while the initial investment may be higher for fiber laser welding machines, the long-term cost efficiency and benefits can make them a smart choice for modern manufacturing.

**Tips:** Always conduct a thorough cost-benefit analysis tailored to your specific production needs; this will offer deeper insights into the financial advantages of investing in fiber laser technology.

Comparative Cost Analysis of Fiber Laser and Traditional Welding Methods

Impact of Fiber Laser Welding on Material Versatility in Manufacturing

Fiber laser welding machines have revolutionized the manufacturing industry by dramatically enhancing the versatility of materials that can be effectively welded. According to a report from Research and Markets, the global fiber laser market is projected to reach $4.26 billion by 2026, demonstrating the increasing adoption of this technology across various sectors. One of the key advantages of fiber lasers is their ability to weld a wide range of materials, including metals, plastics, and composites, with precision and efficiency. This versatility allows manufacturers to streamline their processes and reduce the need for multiple welding systems, making it an attractive option for both small-scale and large-scale production.

Tips: When considering fiber laser welding, it’s essential to analyze the specific materials you’ll be working with. Fiber lasers can penetrate deeper into thicker materials, which is ideal for applications in automotive and aerospace industries. Additionally, leveraging this technology can lead to significant cost savings through reduced operational times and material waste.

Moreover, fiber lasers exhibit a high energy efficiency rate of approximately 25%, as reported by the International Journal of Advanced Manufacturing Technology. This means manufacturers can achieve stronger welds at lower energy costs compared to traditional welding methods. Adopting fiber laser technology not only enhances material versatility but also contributes to sustainable manufacturing practices.

Industry Case Studies: Fiber Laser Welding Success Stories and Metrics

Fiber laser welding machines are transforming the landscape of modern manufacturing, yielding impressive results that are supported by industry case studies. For instance, a leading automotive manufacturer reported a 30% reduction in production time by integrating fiber laser welding into their assembly line. This enhancement not only expedited the welding process but also improved joint quality, leading to a 25% decrease in post-weld inspections. Companies leveraging fiber laser technology are capitalizing on its precision and speed, resulting in less material waste and significantly lower operational costs.

Fiber laser welding machines are transforming the landscape of modern manufacturing, yielding impressive results that are supported by industry case studies. For instance, a leading automotive manufacturer reported a 30% reduction in production time by integrating fiber laser welding into their assembly line. This enhancement not only expedited the welding process but also improved joint quality, leading to a 25% decrease in post-weld inspections. Companies leveraging fiber laser technology are capitalizing on its precision and speed, resulting in less material waste and significantly lower operational costs.

In the aerospace sector, studies indicate that fiber laser welding can achieve weld speeds of up to 40 inches per minute, compared to traditional methods that operate at about 10 inches per minute. This dramatic increase in efficiency allows manufacturers to meet tight deadlines and scale their production output without sacrificing quality. One particular case showcases a manufacturer that saw a 50% increase in production capacity after switching to fiber laser welding, drastically enhancing their competitive edge.

Tip: When considering the adoption of fiber laser welding, assess the specific needs of your projects to take full advantage of its capabilities. Furthermore, investing in training for your workforce can maximize the benefits of this technology, ensuring optimal performance and output quality.

Future Trends: Advancements in Fiber Laser Technology for Manufacturing

Advancements in fiber laser technology are reshaping modern manufacturing, particularly in sectors like automotive and aerospace. Recent studies indicate that the global laser welding market is projected to grow significantly, with a compound annual growth rate (CAGR) exceeding 8% between 2024 and 2030. This growth is largely driven by the increasing demand for lightweight materials and the precision required in producing electric vehicles. Fiber lasers, known for their efficiency and productivity, enable manufacturers to achieve tighter tolerances and improved weld quality, essential for meeting the stringent safety and performance standards in these industries.

In addition to welding, the integration of innovative technologies like beam shaping and in-situ monitoring is revolutionizing laser-assisted manufacturing processes. Research highlighted in a recent review published in Optics and Laser Technology showcases how digital modeling and real-time monitoring are enhancing the capability to manufacture complex thermoset composites. As the industry evolves, these advancements are not only boosting the pace of production but also fostering sustainability by reducing material waste. With over 680 startups actively innovating in the laser sector, the momentum toward improved laser technologies signifies a robust opportunity for businesses to enhance their manufacturing capabilities and remain competitive in the marketplace.

FAQS

: The key innovations include improved laser beam quality, enhanced energy efficiency, and faster processing speeds, resulting in more precise and efficient welding processes.

It allows for cleaner welds with less heat distortion, reducing the risk of material damage and ensuring product integrity.

Various industries benefit, particularly in cutting, welding, and drilling, due to the high energy density allowing deep penetration welding of thicker materials.

Initially, yes, fiber laser welding machines may have a higher purchase price compared to traditional machines.

Fiber lasers have lower operational costs, reduced electricity consumption, minimal maintenance, and higher speeds, leading to increased productivity and cost savings over time.

Focusing on lifecycle costs reveals that traditional welding methods can incur higher cumulative costs in labor, consumables, and downtime, despite lower initial investments.

The greater precision and finer welds achieved by fiber lasers can lead to reduced material waste, resulting in significant savings on material costs.

Conduct a thorough cost-benefit analysis tailored to specific production needs to gain deeper insights into the financial advantages of investing in fiber laser welding.

Conclusion

Fiber Laser Welding Machines offer significant advantages in efficiency and speed, revolutionizing modern manufacturing. Key technical innovations have propelled this technology forward, making it a preferred choice over traditional welding methods. A comparative cost analysis reveals that while initial investment may be higher, the long-term savings and increased productivity justify the transition to fiber laser welding.

The versatility of materials that can be welded using fiber laser technology expands manufacturing capabilities, allowing for greater design flexibility. Case studies from various industries highlight success stories and measurable outcomes, illustrating the practical benefits of adopting fiber laser welding. As advancements continue, the future of fiber laser technology promises further improvements, solidifying its role as a cornerstone in the evolution of manufacturing processes. Companies like Maven Laser Automation Co., Ltd. are at the forefront of this transition, providing cutting-edge laser systems and automation solutions since 2008.

Related Posts

-

Find the Right Manufacturer for the Best 1000w Handheld Fiber Laser Welding Machine

-

Exploring Top Alternatives to the Best Fiber Laser Machine for Your Business Needs

-

Exploring the Unique Features and Applications of Various Compact Fiber Laser Cutting Machines

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

-

Exploring Growth Opportunities for Portable Pulse Laser Cleaner Industry at China Import and Export Fair 2025

-

Comprehensive Solutions for Efficient Rust Removal with the Best 3000W 4-In-1 Laser Cleaning Machine

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top