What is an Automatic Laser Welding Machine and How Does It Work?

Table of Contents

- What is an Automatic Laser Welding Machine?

- Key Components of Automatic Laser Welding Machines

- How Automatic Laser Welding Machines Work

- Types of Laser Technology Used in Welding

- Applications of Automatic Laser Welding Machines

- Benefits of Using Automatic Laser Welding Machines

- Future Trends in Laser Welding Technology

- FAQS

- Conclusion

- Related Posts

The Automatic Laser Welding Machine is really changing the game in manufacturing. It uses focused laser beams to join materials quickly and with incredible precision. Honestly, this tech has totally transformed industries like automotive and electronics. Companies like ABC Laser Technologies are really leading the way with top-notch solutions.

Compared to the old-school welding methods, this laser thing gives you cleaner, stronger welds. Plus, it cuts down on heat-affected zones, so there's less worry about warping or distortion. But, fair warning, it’s not perfect for every application. Some materials or thicknesses still do better with traditional techniques.

As more industries jump on board with this advanced tech, there are still some hurdles. You really need skilled operators to fine-tune the machine settings and get the best results. Investing in proper training is a must. Also, it’s important for companies to think carefully about how this fits into their existing workflows. Mastering the Automatic Laser Welding Machine might just be the key to staying ahead in the future of manufacturing.

What is an Automatic Laser Welding Machine?

An automatic laser welding machine is a powerful tool used in various manufacturing processes. It employs focused laser beams to join materials, mainly metals. The speed and precision of this technology stand out. This machine can effectively produce high-quality welds with minimal distortion. The heat generated by the laser is intense and very controlled.

Working with an automatic laser welding machine involves careful setup. Operators must ensure proper alignment of the materials. If the positioning is incorrect, the weld could be compromised. This mistake can lead to weak joints. Regular maintenance is crucial to avoid unexpected breakdowns. Calibration of the laser settings is also essential for consistent results.

Tips: Always check the focus of the laser before starting. A misaligned beam can waste materials. Practice on scrap pieces to perfect your technique. Understand that errors might occur, so keep a positive mindset for improvement. The learning curve can be challenging but rewarding. Adapting to this technology requires patience and persistence.

Automatic Laser Welding Machine Usage Statistics

Key Components of Automatic Laser Welding Machines

Automatic laser welding machines are transforming manufacturing. They provide precision and efficiency. Understanding their key components is essential for effective operations.

A laser source creates a focused beam of light. This beam is directed to the workpieces through optical fibers. The welding head plays a crucial role. It focuses the laser beam onto the material to achieve the desired weld quality. Proper alignment is vital here. Users often overlook this, leading to inconsistent results.

Cooling systems also matter. They maintain the correct temperature during operations. If the machine overheats, it can damage both the equipment and the workpieces. Regular maintenance is key for longevity.

Tips: Always check the alignment before starting your welding tasks. This simple step can save you time and materials. Make sure to inspect the cooling system regularly. A small flaw can lead to significant issues. Understanding these components can optimize your welding process. Consider scheduling routine training for your team. Familiarity boosts productivity and reduces mistakes.

How Automatic Laser Welding Machines Work

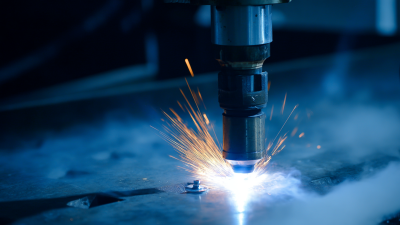

Automatic laser welding machines utilize high-intensity laser beams to join materials together. They focus on a small area, generating heat that melts the material. This process is fast and precise, making it ideal for various industries. The machine uses a controlled movement to ensure accuracy during welding. This precision minimizes defects and ensures a strong bond.

When working with laser welding machines, it is crucial to understand their settings. Adjusting the power and speed can greatly affect weld quality. Not enough heat may result in weak joints. Too much heat can cause warping or burn-through. Finding the right balance takes practice and careful observation.

Tips: Always conduct a test weld before starting a large project. This will help identify the optimal parameters for your specific materials. Regular maintenance of the machine is essential, as worn or damaged components can lead to inconsistent results. Keep the work area clean to avoid contamination, which can also compromise weld quality.

Types of Laser Technology Used in Welding

Laser welding technology is transforming the manufacturing landscape. Different types of laser technologies cater to various welding needs. Solid-state lasers, fiber lasers, and CO2 lasers are commonly used in this process. Each type has unique advantages, suitable for specific materials and applications.

Solid-state lasers rely on crystal media. They produce high-quality beams, making them ideal for precise welding tasks. On the other hand, fiber lasers use optical fibers for light amplification, leading to lower operational costs and greater energy efficiency. They excel in welding thin materials and are increasingly popular in automation.

CO2 lasers, the oldest among these, offer high power and versatility. However, they require more maintenance and are less efficient than their counterparts. As manufacturers adopt automation, the choice of laser technology becomes critical. Each option demands careful consideration to ensure optimal performance and efficiency. Many still grapple with selecting the right technology for their specific needs.

Applications of Automatic Laser Welding Machines

Automatic laser welding machines are transforming industries with their precision and efficiency. These machines are extensively used in automotive manufacturing, aerospace, and electronics. In automotive applications, laser welding provides seamless joints in bodywork. This process enhances overall vehicle safety and reduces weight. According to a recent industry report, the automotive sector accounts for nearly 35% of laser welding use.

In electronics, laser welding is crucial for assembling components. It's used to join delicate parts like circuit boards without causing damage. This is vital, as reported in industry studies, indicating a growing demand in electronics has led to a 20% increase in laser welding techniques over the past year. However, the transition to laser welding is not always smooth. Companies face challenges in training staff and integrating new technologies.

Moreover, while the efficiency of these machines is impressive, some businesses report initial setup costs can be high. Ongoing maintenance and calibration are essential for optimal performance. This highlights the need for careful planning and budget allocation in adopting laser welding solutions. In summary, the applications of automatic laser welding machines offer revolutionary benefits, but they come with challenges that require thoughtful consideration.

What is an Automatic Laser Welding Machine and How Does It Work? - Applications of Automatic Laser Welding Machines

| Application Area | Material Types | Advantages | Typical Industries |

|---|---|---|---|

| Automotive Manufacturing | Steel, Aluminum | High speed, precision | Car manufacturers |

| Electronics | Copper, Gold | Minimal heat affected zone, fine welds | Consumer electronics, Aerospace |

| Medical Devices | Stainless Steel, Titanium | Sterile, non-contact welding | Medical tooling, Surgical implants |

| Jewelry Manufacturing | Gold, Silver | No additional material needed, aesthetic finish | Jewelry designers, Artisans |

| Aerospace | Aluminum Alloys, Composites | Lightweight, low distortion | Aircraft manufacturers, Spacecraft assemblies |

Benefits of Using Automatic Laser Welding Machines

Automatic laser welding machines are revolutionizing the manufacturing process. These machines utilize a high-powered laser beam to join materials together. The precision of the laser allows for clean and efficient welds, minimizing the need for extensive post-welding work. This means higher productivity and reduced operational costs.

One significant benefit of using these machines is their capability to weld complex geometries effortlessly. They can easily adapt to various shapes and sizes. This flexibility enables manufacturers to innovate without being hindered by traditional welding methods. Additionally, laser welding reduces distortion and heat-affected zones, improving the final quality of welded products.

Tips: Always ensure proper alignment of parts before welding. Misalignment can lead to weak joints. Also, consider the thickness of the materials being welded; adjustments may be necessary. Lastly, regular maintenance of the machine is critical. It prolongs the lifespan and ensures consistent operation.

Investing in an automatic laser welding machine can enhance production efficiency. However, training for operators is essential. Understanding how to set parameters correctly is key. Small errors can lead to significant defects. Reflecting on machine performance regularly can identify areas for improvement. This proactive approach can save time and costs in the long run.

Future Trends in Laser Welding Technology

The future of laser welding technology is poised for exciting advancements. According to a recent market report, the laser welding market is expected to grow at a compound annual growth rate (CAGR) of over 5% by 2028. This growth is largely driven by the increasing demand for automation in manufacturing processes. Industries are recognizing the need for precision and efficiency in welding applications.

Emerging trends include the integration of artificial intelligence (AI) and machine learning into laser welding systems. These technologies enable machines to learn from previous welding tasks and adapt in real-time, which can significantly improve welding quality and reduce error rates. Additionally, smaller and more compact laser systems are being developed, allowing for easier integration into existing production lines, creating flexible manufacturing environments.

Despite these advancements, challenges remain. The initial investment costs for advanced laser systems can be prohibitive for smaller manufacturers. There is also a steep learning curve associated with the implementation of new technologies. Industry professionals often report difficulties in adapting their workforce to new processes. These factors highlight the need for ongoing training and support in laser welding technology.

FAQS

: This product aims to enhance user experience with specific features and benefits.

Follow the guidelines provided to maximize effectiveness. Proper usage details are crucial.

Some users have reported minor effects. It's important to monitor your own experience.

Yes, but listen to your body. Adjust usage based on personal comfort levels.

Generally safe, but consult a professional if you have health concerns. Individual sensitivities vary.

Results may vary. Some notice changes within days, while others need more time.

If you’re unhappy, consider reaching out for assistance. Reflect on your experience for insights.

Mixing products can be tricky. Assess compatibility carefully before trying.

Don’t stress too much. Regular consistency helps but missing a few times won’t be detrimental.

Yes, a return policy exists. Review it carefully to understand the terms and conditions.

Conclusion

An Automatic Laser Welding Machine is a highly advanced tool that utilizes laser technology for precision welding applications. This machine is composed of key components such as a laser source, optics, control systems, and welding heads that work together to create strong and precise welds on various materials. The operation of an Automatic Laser Welding Machine involves focusing a high-energy laser beam onto the workpiece, generating intense heat that causes the materials to melt and fuse together.

Different types of laser technology, including fiber lasers and CO2 lasers, are used depending on the specific welding requirements. These machines are widely employed in industries such as automotive, aerospace, and electronics, where high-speed and high-quality welding are essential. The benefits of using Automatic Laser Welding Machines include faster production rates, minimized thermal distortion, and enhanced weld quality. As advancements continue, the future trends in laser welding technology promise even greater efficiency and capabilities.

Related Posts

-

Comprehensive Guide to Selecting the Ideal Laser Welding Machine for Various Mold Applications

-

Ultimate Checklist for Sourcing the Best Laser Metal Welding Solutions Globally

-

Revolutionizing Precision: The Science Behind Laser Welding Machines Explained

-

2025 Top 10 Laser Welding Robots: Revolutionizing Industrial Automation

-

What is the Efficiency of 200w Pulse Laser Cleaning Machine for Wood Applications

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top