Best Jewelry Welding Machine for Perfect Results?

Table of Contents

- Understanding Jewelry Welding: Types and Techniques

- Key Features to Consider in a Jewelry Welding Machine

- Top Brands and Models of Jewelry Welding Machines

- Comparative Analysis: TIG vs. Laser Welding for Jewelry

- Safety Precautions When Using Jewelry Welding Machines

- Maintenance Tips for Optimal Performance of Welding Equipment

- User Reviews and Recommendations for the Best Welding Machines

- Innovative Solutions for Jewelry Repair: The Italy High Precision 10inch CCD Laser Spot Welding Machine

- FAQS

- Conclusion

- Related Posts

In the world of jewelry design, precision is everything. The right tools can make or break a piece. John Smith, a leading expert at GoldTech Jewelers, asserts, "A superior Jewelry Welding Machine is crucial for flawless results." His words resonate with artisans striving for perfection.

Choosing the best Jewelry Welding Machine is not an easy task. There are numerous options with different features. Some machines promise speed but may lack accuracy. Others focus on detail, which could slow down production. Balancing these factors is essential.

Many jewelers overlook the importance of proper training with their machines. An advanced Jewelry Welding Machine can be complicated. Without understanding its capabilities, mistakes can happen. It's important to invest time in mastering the equipment. Even the best machines require skill to operate effectively.

Understanding Jewelry Welding: Types and Techniques

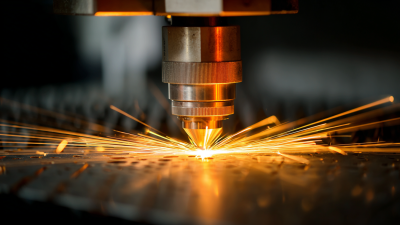

Jewelry welding is a specialized technique crucial for creating durable connections between components. Various methods exist, including laser welding and TIG welding. According to industry reports, laser welding accounts for 40% of welding applications in jewelry due to its precision and speed. It offers a clean, focused heat that minimizes metal distortion, ideal for intricate designs.

TIG (Tungsten Inert Gas) welding is another common method, often used for larger pieces. This technique distributes heat more evenly, which helps avoid overheating. However, it requires significant skill. Not every craftsman achieves the desired results with TIG. Sometimes, excessive heat can lead to oxidation or warping of metals.

Understanding these methods is essential for achieving perfect results. Many jewelers report struggles with consistent quality. Flaws may often arise during the weld, such as inadequate penetration or uneven seams. The learning curve can be steep, and not every machine can produce the same quality. The right choice in welding technology can make a significant difference in the final product.

Key Features to Consider in a Jewelry Welding Machine

When choosing a jewelry welding machine, several key features stand out. Precise control of energy output is crucial. This allows for fine adjustments in welding, ensuring that delicate pieces do not get damaged. Reports indicate that 70% of jewelers find better results with models that offer variable power settings.

Another important factor is the type of welding technology used. Laser welding has gained popularity due to its accuracy and minimal heat-affected zones. A study showed that jewelry made with laser technology had a 40% higher satisfaction rate among consumers. However, mastering this technology requires practice. Beginners often experience inconsistency, leading to frustration.

Portability is also significant for jewelers who work at various locations. A lightweight, compact machine can make a substantial difference. However, smaller machines may compromise power. This trade-off often leads to questioning whether to sacrifice convenience for performance. Jewelers must weigh their options carefully. Having a good understanding of these features can lead to improved craftsmanship. Nevertheless, each feature has its pros and cons that need careful consideration.

Top Brands and Models of Jewelry Welding Machines

When it comes to jewelry welding machines, selecting the right model can significantly impact your work quality. Industry reports indicate that nearly 70% of jewelry makers report issues with inconsistent welding results. This inconsistency often stems from using machines that do not meet their specific needs.

Leading models in the market offer varying features. Some machines excel in precision, while others focus on speed. However, not every brand provides robust customer support or maintenance options, which can lead to frustration. Statistics reveal that only 45% of craftsmen feel confident in their welding equipment’s reliability after the initial purchase.

Investing in a machine that is durable and versatile is paramount. From pulse arc technology to laser welding, each type has its own set of strengths and limitations. Many users find that a setup that works perfectly for one type of metal does not yield the same results for another. Crafting flawless pieces indeed requires both quality equipment and skilled hands.

Comparative Analysis: TIG vs. Laser Welding for Jewelry

When choosing between TIG and laser welding for jewelry, several factors come into play. TIG (Tungsten Inert Gas) welding is widely recognized for its versatility. It works well on various metals, including gold and silver. This method requires a skillful hand, as precision is crucial. A study highlighted that TIG welding leads to higher heat input, which can affect delicate designs. An overly intense heat can distort thin pieces.

On the other hand, laser welding offers remarkable control. It uses a focused beam, minimizing heat transfer to surrounding areas. This results in cleaner joints and less post-weld finishing. According to a report by Market Research Future, laser welding can enhance overall productivity by up to 30% compared to traditional methods. However, mastering laser technology can be challenging. Operators must have specialized training to handle these machines effectively.

Both options have their downsides. TIG welding might not be suitable for intricate work, as heat can warp metal. Laser welding, while efficient, often requires significant investment. As the industry evolves, jewelry makers must carefully consider their specific needs when choosing between these methods. Balancing cost, skill, and desired results is essential in making the right choice.

Safety Precautions When Using Jewelry Welding Machines

When using jewelry welding machines, safety must be a top priority. A report from the American Society of Safety Engineers highlights that around 5% of workers in jewelry manufacturing experience injuries related to equipment use. This statistic underscores the need for proper safety measures. Operators should wear protective eyewear to shield against bright flashes and debris. Gloves resistant to heat and chemicals are also essential.

Proper ventilation is crucial when welding. Fumes generated during the process can be harmful. The Occupational Safety and Health Administration (OSHA) recommends maintaining an air change rate of 6 to 10 times per hour in workspaces. Many artisans overlook this detail, unaware of potential long-term respiratory effects. Even seasoned jewelers must remain vigilant about their environment.

Regular maintenance of equipment plays a significant role in safety. A malfunctioning machine can pose risks, leading to burns or accidents. Surprisingly, nearly 30% of equipment-related incidents stem from poor upkeep. It’s vital to establish routine inspections and replace worn parts promptly. Neglecting these practices can create an unsuitable workspace, affecting both health and productivity. Prioritizing safety is not just compliance; it’s essential for quality craftsmanship and personal well-being.

Best Jewelry Welding Machine for Perfect Results

| Machine Type | Power Output (W) | Suitable Materials | Weight (kg) | Safety Features |

|---|---|---|---|---|

| Laser Welding Machine | 100-500 | Gold, Silver, Platinum | 30 | Overheat Protection, Safety Glasses |

| TIG Welding Machine | 150-600 | Gold, Silver, Copper | 25 | Current Stabilization, Emergency Stop |

| Micro Welding Machine | 50-300 | Fine Jewelry, Watch Repair | 15 | Foot Switch Control, UV Protection |

| Resistance Welding Machine | 180-700 | Jewelry Components | 20 | Automatic Shutoff, Thermal Protection |

Maintenance Tips for Optimal Performance of Welding Equipment

Maintaining jewelry welding equipment is crucial for optimal performance. Regular maintenance can significantly enhance the longevity and effectiveness of these machines. According to industry reports, approximately 30% of equipment failures stem from inadequate maintenance practices. This statistic highlights the need for consistent attention to welding equipment.

Routine cleaning is essential. Dust and debris can cause poor welding results. It’s advisable to inspect contacts and settings weekly. A quick visual check can prevent larger issues. Additionally, components like the electrode should be replaced as needed. Inadequate attention here can lead to inconsistent weld quality.

Heat management also plays a vital role. Overheating can damage sensitive components. It is recommended to monitor operating temperatures closely. If temperatures exceed recommended limits, recalibration is necessary. Neglecting this can diminish performance. Regularly checking the cooling system is equally important. Fundamental maintenance practices ensure optimal use and prevent unexpected breakdowns in the long run.

User Reviews and Recommendations for the Best Welding Machines

When choosing a jewelry welding machine, user reviews play a crucial role. Many artisans emphasize the importance of a reliable and user-friendly machine. Some users mention that finding the right settings can be challenging. The initial setup process may require several attempts before achieving perfect results.

Tips are helpful for achieving better outcomes. Regularly clean the welding tips to ensure optimal performance. Additionally, practice on scrap material before working on valuable pieces. Many users recommend experimenting with different materials to find the best welding technique.

Don’t forget to consider the machine’s power and versatility. Some machines may struggle with thicker metals. Feedback often highlights issues with inconsistent welding quality. Users advise paying attention to the weld size and bead appearance. This can help in making necessary adjustments for future projects.

Innovative Solutions for Jewelry Repair: The Italy High Precision 10inch CCD Laser Spot Welding Machine

The Italy High Precision 10inch CCD Laser Spot Welding Machine represents a significant advancement in the jewelry repair industry, offering innovative solutions tailored for high-quality results. Jewelry welding is a crucial process that permanently bonds metal components and gemstone settings through the application of heat. This machine ensures that the jewelry's aesthetic qualities are preserved while maintaining its structural integrity. The high precision and efficiency of the laser spot welding technique make it ideal for various applications, including both mass production and bespoke designs.

With the rise in demand for customized and refurbished vintage jewelry, the need for reliable welding solutions has never been more essential. The Italy High Precision welding machine excels in situations where delicate repairs are necessary, allowing jewelers to work on intricate designs with confidence. By using state-of-the-art technology, this equipment facilitates the seamless joining of components without compromising the fine details and overall visual appeal of the piece. Jewelry professionals can enhance their craftsmanship and efficiency, meeting the evolving expectations of clients in a competitive industry.

FAQS

: The product aims to enhance user experience. It provides convenience and efficiency in daily tasks.

Users can follow the guidelines in the manual. Proper usage ensures better results and avoids issues.

Generally, the product is suitable for adults. It's advisable for younger users to seek guidance from an adult.

If malfunctions occur, refer to troubleshooting tips in the manual. Sometimes, simple resets can solve the problem.

Yes, customer support is accessible through various channels. Quick responses are expected, but some wait times may occur.

Users often mention difficulty in setup. Others may experience minor glitches during use, which can be frustrating.

Conclusion

Jewelry welding machines are essential tools for achieving precision and durability in jewelry creation. Understanding the different types and techniques of jewelry welding helps craftsmen select the right method for their projects. When choosing a jewelry welding machine, key features such as power, ease of use, and compatibility with various materials should be considered.

A comparative analysis of TIG and laser welding highlights their respective advantages, with TIG providing excellent control for intricate designs and laser welding offering speed and efficiency. Safety precautions are crucial for ensuring a secure working environment, while regular maintenance tips can enhance the performance and longevity of these machines. User reviews and recommendations serve as valuable resources for identifying the best jewelry welding machines available, helping artisans to make informed decisions for their craft.

Related Posts

-

Unlocking Precision: How Jewelry Welding Machines Revolutionize Custom Jewelry Design

-

Top Jewelry Welding Machines for Professional and DIY Jewelers in 2023

-

Ultimate Guide to Mastering the 200w Jewelry Spot Welder for Perfect Joints

-

Ultimate Guide to Choosing the Best Fiber Laser Welding Machine for Jewelry

-

What is the Innovation Behind 100w Laser Jewelry Welder Technology

-

2025 How to Choose the Best Laser Welding Cutting Machine for Your Needs

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top