7 Best Reasons to Invest in a Rust Cleaning Laser Machine

Table of Contents

- Benefits of Precision: How Rust Cleaning Lasers Enhance Surface Integrity

- Cost-Effectiveness of Investing in State-of-the-Art Rust Cleaning Equipment

- Environmental Advantages: Why Laser Technology is Greener for Rust Removal

- Versatility Unleashed: Applications Beyond Rust Cleaning with Laser Machines

- Safety First: How Rust Cleaning Lasers Reduce Occupational Hazards

- Time Efficiency: The Speed of Rust Removal with Laser Technology

- FAQS

- Related Posts

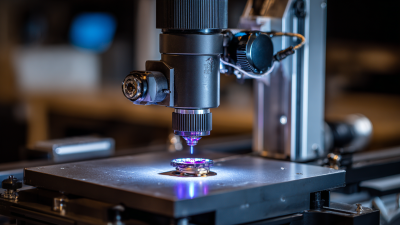

In today's rapidly advancing industrial landscape, investing in high-performance equipment has become essential for maintaining efficiency and quality. One such pivotal investment is the Rust Cleaning Laser Machine, which stands out for its precision and effectiveness in surface preparation and restoration. At Maven Laser Automation Co., Ltd., a leading manufacturer of laser systems based in Shenzhen, China, we recognize the critical role that innovative technologies play in enhancing operational capabilities. Founded in 2008, our expertise in laser case design, production, and sales uniquely positions us to offer cutting-edge solutions that cater to the evolving needs of various industries. In this blog, we will explore the seven best reasons to invest in a Rust Cleaning Laser Machine, illustrating how this advanced technology can transform your business operations and yield significant long-term benefits.

Benefits of Precision: How Rust Cleaning Lasers Enhance Surface Integrity

Rust cleaning laser machines are revolutionizing the way we approach surface integrity in various industries. These precision tools utilize high-intensity laser beams to effectively remove rust and contaminants, ensuring that the underlying surfaces remain intact. Unlike traditional methods, which can cause abrasion and damage to the material, rust cleaning lasers provide a non-contact solution that preserves the integrity of the surface. This is particularly crucial in sectors such as aerospace and automotive, where maintaining the quality of surfaces is essential for safety and performance.

The precision of laser cleaning also enhances the longevity of components. By removing rust and debris without altering the material structure, these machines prevent further deterioration and prolong the life of valuable assets. Additionally, the clean surface achieved through laser technology improves the adhesion of coatings and paints, leading to better protection against future corrosion. With increased accuracy, efficiency, and a minimal environmental impact, investing in a rust cleaning laser machine becomes an intelligent choice for companies dedicated to maintaining high standards in surface integrity.

7 Best Reasons to Invest in a Rust Cleaning Laser Machine

| Reason | Benefit | Impact on Surface Integrity | Cost Efficiency |

|---|---|---|---|

| Precision Cleaning | Removes rust without affecting underlying material | Maintains structural integrity | Reduces maintenance costs long-term |

| Versatility | Applicable to various metal surfaces | No damage to sensitive components | Saves on multiple cleaning tools |

| Environmental Safety | No harmful chemicals used | Protects the environment | Less liability for hazardous waste |

| Time Efficiency | Faster than traditional methods | Increases throughput | Shortens downtime |

| Automation Friendly | Easily integrated into automated systems | Consistent results every time | Enhances overall productivity |

| Minimal Waste | Generates less material loss | Better material usage | Lower replacement costs |

| Aesthetic Improvement | Enhances visual appeal of surfaces | Improves marketability of products | Increases resale value |

Cost-Effectiveness of Investing in State-of-the-Art Rust Cleaning Equipment

Investing in state-of-the-art rust cleaning laser machines presents a compelling case for cost-effectiveness in various industries. According to a recent report by the Global Laser Cleaning Market, the industry was valued at approximately $160 million in 2021 and is projected to grow at a CAGR of 15% through 2028. This growth is driven by the increasing need for efficient and environmentally friendly rust removal solutions, which traditional methods often lack. In contrast, laser cleaning technology not only minimizes waste but also reduces labor costs, making it a sustainable choice for businesses looking to optimize their maintenance operations.

Moreover, the adoption of advanced rust cleaning equipment can lead to significant long-term savings. A study by the Amercian National Standards Institute highlights that companies leveraging modern laser cleaning technology have reported up to 50% reduction in cleaning time and up to 80% reduction in the use of solvents compared to conventional methods. This efficiency translates into fewer man-hours and lower operational costs, allowing businesses to divert resources to other areas. Investing in laser cleaning machines not only improves operational efficiency but also enhances safety standards by eliminating hazardous materials typically associated with rust removal.

Environmental Advantages: Why Laser Technology is Greener for Rust Removal

Laser technology for rust removal is not just an innovative alternative; it also offers significant environmental advantages. Unlike traditional methods, which often require harsh chemicals and produce harmful waste, laser cleaning minimizes environmental impact. According to a report by the European Clean Laser Association, laser rust removal can reduce the use of toxic substances by up to 90%, contributing to cleaner air and less soil contamination. This method uses focused light beams to remove rust and contaminants without the need for abrasive materials or chemical agents, effectively making it a greener choice.

Tip: When considering the switch to laser technology, assess the specific needs of your projects. Factor in the scale of rust removal required and the surfaces involved to utilize the laser cleaner effectively.

Additionally, laser cleaning machines are energy-efficient, consuming up to 50% less power compared to conventional methods. This efficiency translates to a reduction in carbon emissions, aligning with the growing demand for sustainable practices in industrial operations. Furthermore, laser technology results in less waste generation, making it an eco-friendly choice for businesses committed to reducing their carbon footprint.

Tip: Regular maintenance and calibration of your laser cleaning machine can optimize energy use, ensuring that you remain economically and environmentally conscious.

Environmental Advantages of Investing in Rust Cleaning Laser Machines

Versatility Unleashed: Applications Beyond Rust Cleaning with Laser Machines

Laser cleaning technology has revolutionized various industries beyond its primary application of rust removal. According to a report by ResearchAndMarkets, the global laser cleaning market is projected to grow at a CAGR of 5.2% from 2021 to 2026. This growth is largely attributed to the versatility of laser machines, enabling operators to effectively clean a range of surfaces, including metal, stone, and even wood. The precision of laser cleaning allows for detailed work in restoration projects and delicate applications, making it invaluable in sectors such as art restoration, aerospace, and automotive manufacturing.

In addition to rust cleaning, laser machines are increasingly employed for surface preparation, such as enhancing adhesion for coatings or paint. A study by the National Institute of Standards and Technology (NIST) indicates that settings utilizing laser surface treatment report up to a 30% increase in adhesion performance, significantly improving the durability and lifespan of coatings. Moreover, the capability of lasers to remove contaminants without the need for harsh chemicals presents an eco-friendly solution that resonates with today's sustainability goals. With advancements in technology, laser cleaning is becoming a go-to method for a variety of industrial applications, showcasing its adaptability and efficiency in meeting diverse cleaning needs.

Safety First: How Rust Cleaning Lasers Reduce Occupational Hazards

In industrial sectors, safety is a paramount concern, particularly when dealing with hazardous materials like rust. Traditional rust removal methods often involve toxic chemicals or abrasive tools that pose significant risks to workers’ health. However, investing in a rust cleaning laser machine can dramatically reduce these occupational hazards. These advanced laser systems utilize high-intensity light beams to remove rust without the need for harmful chemicals, significantly lowering exposure to toxic substances. This innovation not only enhances workplace safety but also fosters a more sustainable approach to rust management.

At Maven Laser Automation Co., Ltd., we recognize the importance of merging safety with effective rust removal solutions. Founded in 2008 in Shenzhen, we specialize in the design, production, and sales of high-quality laser systems tailored to meet the needs of various industries. Our rust cleaning laser machines exemplify our commitment to innovation and safety, allowing companies to maintain a clean and secure working environment while increasing productivity. With our state-of-the-art automation solutions, businesses can efficiently tackle rust issues, ensuring a safer workplace for all employees.

Time Efficiency: The Speed of Rust Removal with Laser Technology

Investing in a rust cleaning laser machine offers a significant advantage in time efficiency, a crucial factor in any industrial cleaning operation. Traditional rust removal methods—including sandblasting and chemical treatments—can take hours or even days to complete, incurring substantial labor costs and downtime. In contrast, laser technology can minimize rust removal times dramatically. According to a study by the American Industrial Cleaners Association, laser cleaning can reduce surface preparation time by up to 80%, allowing manufacturers to restore equipment and surfaces rapidly, thereby limiting production downtime.

Moreover, precision is another important factor that contributes to time savings. Laser cleaning machines can target rust precisely without damaging the underlying materials. This translates to less time spent on post-cleaning inspections and repairs. A report from the National Institute of Standards and Technology indicates that precision cleaning reduces rework rate by approximately 60%. By adopting laser cleaning technology, industries can enhance operational efficiency while ensuring high-quality results, ultimately leading to a faster return on investment.

FAQS

: Investing in these machines leads to cost-effectiveness through reduced labor costs, minimized waste, and significant long-term savings by improving operational efficiency and enhancing safety standards.

The Global Laser Cleaning Market was valued at approximately $160 million in 2021.

The industry is projected to grow at a CAGR of 15% through 2028.

Laser cleaning technology reduces cleaning time by up to 50% and the use of solvents by up to 80%, translating into fewer man-hours and lower operational costs.

Laser cleaning machines reduce occupational hazards by eliminating the need for toxic chemicals and abrasive tools, thus lowering workers' exposure to harmful substances.

Maven Laser Automation Co., Ltd. specializes in the design, production, and sales of advanced laser systems for various industries.

The company was founded in 2008 in Shenzhen.

These laser systems lower waste production and reduce the use of harmful materials, promoting a more sustainable approach to rust management.

Their rust cleaning laser machines are designed to tackle rust issues efficiently while ensuring a clean and secure working environment for employees.

Traditional rust removal methods often involve hazardous materials that pose significant health risks to workers, making safety a paramount concern in industrial sectors.

Related Posts

-

Key Factors to Identify Reliable Manufacturers for the Best 3000w Handheld Laser Cleaner

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

Ultimate Checklist for Sourcing the Best Laser Metal Welding Solutions Globally

-

Mastering the Best Optical Fiber Laser Cutting Machine: A Comprehensive Tutorial for Global Buyers

-

Exploring the Unique Features and Applications of Various Compact Fiber Laser Cutting Machines

-

What Makes Best High Power Laser Welding the Ultimate Choice for Global Buyers

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top