Why Choose a Laser Rust Removal Machine for Your Projects?

Table of Contents

- Understanding Laser Rust Removal Technology

- Key Advantages of Using Laser Rust Removal Machines

- Comparison with Traditional Rust Removal Methods

- Applications of Laser Rust Removal in Various Industries

- Cost-Effectiveness of Laser Rust Removal Solutions

- Environmentally Friendly Aspects of Laser Rust Removal

- Future Trends in Laser Rust Removal Technology

- Exploring the Efficiency and Affordability of the 3 in 1 Handled Laser Cleaning Machine for Rust Removal

- FAQS

- Conclusion

- Related Posts

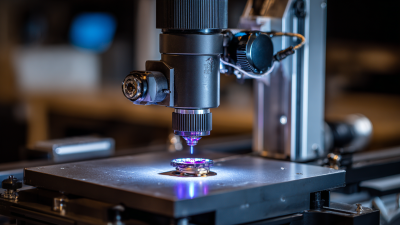

In the hectic world of industrial maintenance, picking the right tools can really make a big difference. A Laser Rust Removal Machine is definitely one of those standout options. It uses cutting-edge tech to zap away rust quickly and efficiently, leaving surfaces looking clean and smooth. Lots of industries depend on sturdy machinery, but not all rust removal methods are created equal, you know?

Traditional ways can be pretty labor-intensive and take ages, plus they can sometimes leave behind residues or even damage the material underneath. That’s where a Laser Rust Removal Machine really shines — it’s precise enough to target rust without messing up the surrounding areas. And best of all, it’s eco-friendly, which is super important these days.

Sure, buying a laser rust remover might seem expensive at first glance, but when you think about the long-term perks, the investment pays off. You get higher productivity and save on labor costs over time. Businesses that stick to old methods risk falling behind, so it’s worth considering how embracing new technology can really help elevate your work. Bottom line? It’s all about evolving and finding smarter solutions to get better results on every project.

Understanding Laser Rust Removal Technology

Laser rust removal technology is transforming the way we approach metal restoration. This technique uses focused laser beams to target rust and corrosion. The laser heats the rust quickly, causing it to break apart. The process is precise and reduces damage to the underlying metal. Unlike traditional methods, it doesn’t produce harmful dust or debris.

When using a laser rust removal machine, clarity is crucial. Ensure you adjust the settings based on the material and rust type. The speed of the laser can vary. Experimenting with different parameters can lead to optimal results.

Here’s a tip: Safety is paramount. Always wear protective gear, such as goggles and gloves. Take time to clear the area from flammable materials. Another tip is to maintain the equipment regularly. This keeps it working efficiently and extends its lifespan.

Sometimes, understanding the machine deeply can help you address minor issues before they escalate. Rust removal is a meticulous process that takes practice and patience. Each project presents unique challenges, testing your skills and knowledge.

Key Advantages of Using Laser Rust Removal Machines

Laser rust removal machines offer several advantages for various projects. One notable benefit is their precision. Laser technology focuses on specific areas, minimizing damage to the surrounding material. This ensures that the underlying surface stays intact, which is crucial for many applications. It allows for selective rust removal, meaning only the affected areas are treated.

Another important advantage is efficiency. Laser rust removal can significantly reduce the time spent on projects. Traditional methods often involve harsh chemicals and labor-intensive processes. In contrast, lasers can quickly eliminate rust without the need for extra materials. The result is a cleaner working environment and less waste generated.

However, it's essential to acknowledge some challenges. Laser systems can be expensive, requiring a significant initial investment. Training is also necessary to operate these machines safely and effectively. Not every project may justify this cost. Assessing your specific needs is vital. Make sure your choice aligns with your goals and budget constraints.

Why Choose a Laser Rust Removal Machine for Your Projects? - Key Advantages of Using Laser Rust Removal Machines

| Advantage | Description | Typical Applications |

|---|---|---|

| Environmentally Friendly | Uses no chemicals and minimizes waste, making it safe for the environment. | Industrial cleaning, automotive shops, restoration projects. |

| Precision | Provides targeted removal without damaging the underlying surface. | Metalworking, art restoration, and sensitive equipment. |

| Speed | Allows for quick processing, reducing downtime on projects. | Manufacturing lines, shipyards, large renovation projects. |

| Versatility | Can be used on various materials including metal, wood, and concrete. | Multi-material repairs, restoration of historical structures. |

| Cost-Effective | Reduces the need for abrasive media and replacement parts, lowering overall costs. | Fabrication, maintenance, and repair operations. |

Comparison with Traditional Rust Removal Methods

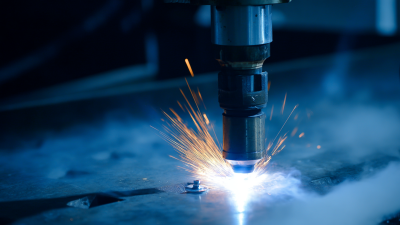

When evaluating rust removal methods, laser rust removal machines present a significant advantage over traditional techniques. According to a recent industry report, approximately 40% of abrasive blasting operations result in surface damage. This can be costly. In contrast, laser technology uses focused light to target rust without harming the underlying metal.

Another aspect to consider is efficiency. Traditional methods, like chemical stripping or sanding, can take hours or even days. Laser removal typically completes the task in a fraction of that time. A study indicated that laser removal can be up to 5 times faster than conventional techniques. Yet, the initial investment in laser machines may deter some businesses.

Moreover, traditional methods often involve extensive cleanup and disposal of hazardous materials. Laser machines produce minimal waste. However, training is necessary to operate these machines effectively. This can pose a challenge for teams initially unfamiliar with the technology. While laser rust removal machines offer numerous benefits, careful consideration of both costs and training needs is essential.

Applications of Laser Rust Removal in Various Industries

Laser rust removal technology has gained traction across various industries, offering precision and efficiency. This method is particularly useful in automotive manufacturing, where rust can affect structural integrity. According to a recent report by Grand View Research, the global laser cleaning market is expected to grow by over 20% annually. This growth is driven by the demand for cleaner, safer production processes.

In shipbuilding, laser rust removal enhances operational efficiency. It significantly reduces surface preparation time compared to traditional methods. A study published in the Journal of Cleaner Production noted that laser cleaning can cut prep time by up to 50%. However, operators must beware of safety protocols. Each machine requires proper training. Inadequate training can lead to accidents or inefficient use of the technology. These challenges highlight that while laser rust removal offers numerous benefits, successful implementation needs careful consideration and planning.

Construction projects also benefit greatly from this technology. Rust on steel structures can lead to costly repairs. By using lasers, teams can maintain structural health efficiently. Yet, cost remains a concern for many businesses. Initial investments can be high. Some companies might underestimate ongoing maintenance needs as well. Balancing cost and efficiency remains crucial for expanding laser rust removal's applications across multiple sectors.

Cost-Effectiveness of Laser Rust Removal Solutions

Laser rust removal machines offer substantial cost-effectiveness for numerous projects. They eliminate the need for harsh chemicals and labor-intensive processes, saving both time and money. Investing in such technology can significantly reduce maintenance costs in the long run. For businesses dealing with rust regularly, this machinery pays off quickly.

When considering this technology, it's crucial to analyze your specific needs. Not all projects require powerful lasers. Sometimes, a less intense option may suffice. Understand the scale of your rust issues before making a purchase. This can help avoid overspending on unnecessary capabilities.

Tips: Regular maintenance of the laser machine is vital. Keeping it in top shape ensures optimal performance. Also, consider the training for your staff. Proper usage can greatly enhance efficiency and effectiveness in rust removal. Remember, the goal is to minimize downtime and maximize productivity.

Environmentally Friendly Aspects of Laser Rust Removal

Laser rust removal machines offer a cleaner, greener alternative for maintenance and restoration projects. Traditional rust removal methods often generate toxic waste. According to a 2021 industry report from the Environmental Protection Agency, over 1.5 million tons of hazardous waste stems from chemical rust removal processes annually. This highlights the pressing need for sustainable options.

Laser technologies utilize focused light to eliminate rust. This process produces minimal waste and no harmful chemicals. A study by the International Journal of Advanced Manufacturing Technology revealed that laser cleaning reduces environmental contamination by up to 90%. The energy consumption of laser systems tends to be lower than that of conventional methods, promoting sustainability. Users can tackle rust without leaving behind environmentally harmful residues.

Still, this technology is not without challenges. Initial costs for laser systems can be high, which may deter some users. Furthermore, operators must undergo proper training to maximize efficiency and safety. These factors can lead to slower adoption rates. Yet, as awareness grows, many may reflect on the long-term benefits of shifting to greener technology. Embracing these innovations is crucial for our planet’s future.

Future Trends in Laser Rust Removal Technology

Laser rust removal technology is experiencing rapid advancements. As industries seek efficient and eco-friendly solutions, lasers are becoming popular. These machines work by emitting concentrated light beams. This targets rust particles effectively while preserving underlying surfaces. The precision of lasers minimizes damage. This technology enhances the longevity of machinery and vehicles.

Tips for using laser rust removal:

- Always wear protective gear.

- A clear workspace improves safety.

- Regular maintenance of your machine ensures optimal performance.

- Adjust the laser settings based on the surface type.

- Higher power might not always be best.

Emerging trends show a rise in automation. Automated systems can efficiently remove rust with minimal human intervention. This reduces labor costs and increases productivity. Artificial intelligence is also stepping in. Machines learn from past jobs, improving outcomes. These trends suggest a promising future for laser rust removal. However, the initial costs may raise concerns. Investing in technology needs careful evaluation.

Exploring the Efficiency and Affordability of the 3 in 1 Handled Laser Cleaning Machine for Rust Removal

The 3 in 1 Handled Laser Cleaning Machine represents a significant advancement in rust removal technology, merging efficiency and affordability in an impressively flexible device. By integrating laser cutting, welding, and cleaning functionalities, this machine provides a comprehensive solution tailored for diverse industrial applications. The capability to perform rust removal effectively is attributed to the high energy density of the laser beam, which can penetrate and evaporate rust without damaging the underlying material. According to a recent report from a leading manufacturing research organization, laser cleaning technology can achieve up to 95% efficiency in rust removal compared to traditional methods, underscoring the economic benefits and time-saving potential for industries reliant on metal substrates.

The portable nature of this machine transforms on-site maintenance and repair processes. Unlike conventional systems that require the workpiece to be fixed on a platform, the handheld design allows operators to navigate large structures and complex geometries effortlessly. This flexibility not only enhances productivity but also reduces the downtime associated with transporting materials to fixed welding sites. Statistics indicate that more than 60% of maintenance operations in manufacturing environments can be performed with portable laser technologies, reflecting the growing trend towards automation and versatility in rust removal practices.

Moreover, the cost-effectiveness of the 3 in 1 Handled Laser Cleaning Machine positions it as an attractive investment for businesses looking to optimize their operations. Analysis suggests that transitioning to laser cleaning solutions can lead to reductions in labor costs and improved operational efficiencies, with a reported 30% decrease in total cleaning time. As industries increasingly prioritize sustainability and cost-saving methods, adopting innovative technologies such as this laser cleaning system is critical for staying competitive in a rapidly evolving market.

FAQS

: The service aims to connect users efficiently. It focuses on enhancing communication among individuals.

You can sign up easily online. Provide basic details like name and email address.

There are various pricing plans available. Some may offer free trials or basic access options.

Yes, you can add personal details and preferences. It helps tailor the experience to your needs.

Technical support is available. Report the issues, and the team usually responds quickly.

User data privacy is a priority. Measures are in place to protect your information from unauthorized access.

Yes, you have the option to delete your account. Consider the consequences before doing so.

Content updates vary. Some features may refresh regularly, while others might need more frequent reviews.

Feedback is welcome and encouraged. It helps improve the overall experience for everyone involved.

There may be limits based on your plan. Review the terms carefully to avoid unexpected restrictions.

Conclusion

The article explores the advantages of using a Laser Rust Removal Machine in various projects, highlighting how this technology operates and its effectiveness in removing rust without damaging the underlying material. The key benefits include precision, reduced need for harmful chemicals, and minimal surface abrasion, making it superior to traditional rust removal methods.

Furthermore, the Laser Rust Removal Machine has diverse applications across industries such as automotive, manufacturing, and restoration, demonstrating its versatility and efficiency. It is also cost-effective and environmentally friendly, aligning with growing sustainability goals in industrial processes. As technology advances, the future of laser rust removal promises innovations that will further enhance its capabilities and applications.

Related Posts

-

Unlocking the Power of Laser Rust Removal Machines: A Comprehensive Guide to Rust-Free Surfaces

-

5 Essential Tips for Optimizing Your Laser Cleaning Head Rack Performance

-

Discover the Finest Laser Cleaner: Premium Quality from China's Leading Manufacturing Factory

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top