Ultimate Guide to Choosing the Best Fiber Laser Welding Machine for Jewelry

Table of Contents

- Understanding Fiber Laser Technology for Jewelry Welding

- Key Features to Look for in a Fiber Laser Welding Machine

- Top Brands and Models of Fiber Laser Welders for Jewelers

- Cost vs. Performance: What to Expect from Fiber Laser Welding Machines

- Maintenance Tips for Longevity of Your Fiber Laser Welder

- Common Applications of Fiber Laser Welding in Jewelry Making

- FAQS

- Conclusion

- Related Posts

In recent years, the jewelry industry has witnessed a significant transformation fueled by advancements in technology, particularly with the introduction of the Fiber Laser Welding Machine for Jewelry. According to a report by MarketsandMarkets, the laser welding market is projected to reach $6.4 billion by 2025, driven by the increasing demand for precision and efficiency in metalworking processes. Maven Laser Automation Co., Ltd., a leading manufacturer based in Shenzhen, China, has been at the forefront of this evolution since its establishment in 2008. With a focus on providing innovative laser systems and professional automation solutions, Maven Laser has enabled jewelers to enhance their craftsmanship while ensuring high-quality welds. As the market evolves, selecting the right Fiber Laser Welding Machine becomes crucial for jewelry businesses to remain competitive and maximize their production capabilities. This ultimate guide aims to help you navigate the selection process effectively.

Understanding Fiber Laser Technology for Jewelry Welding

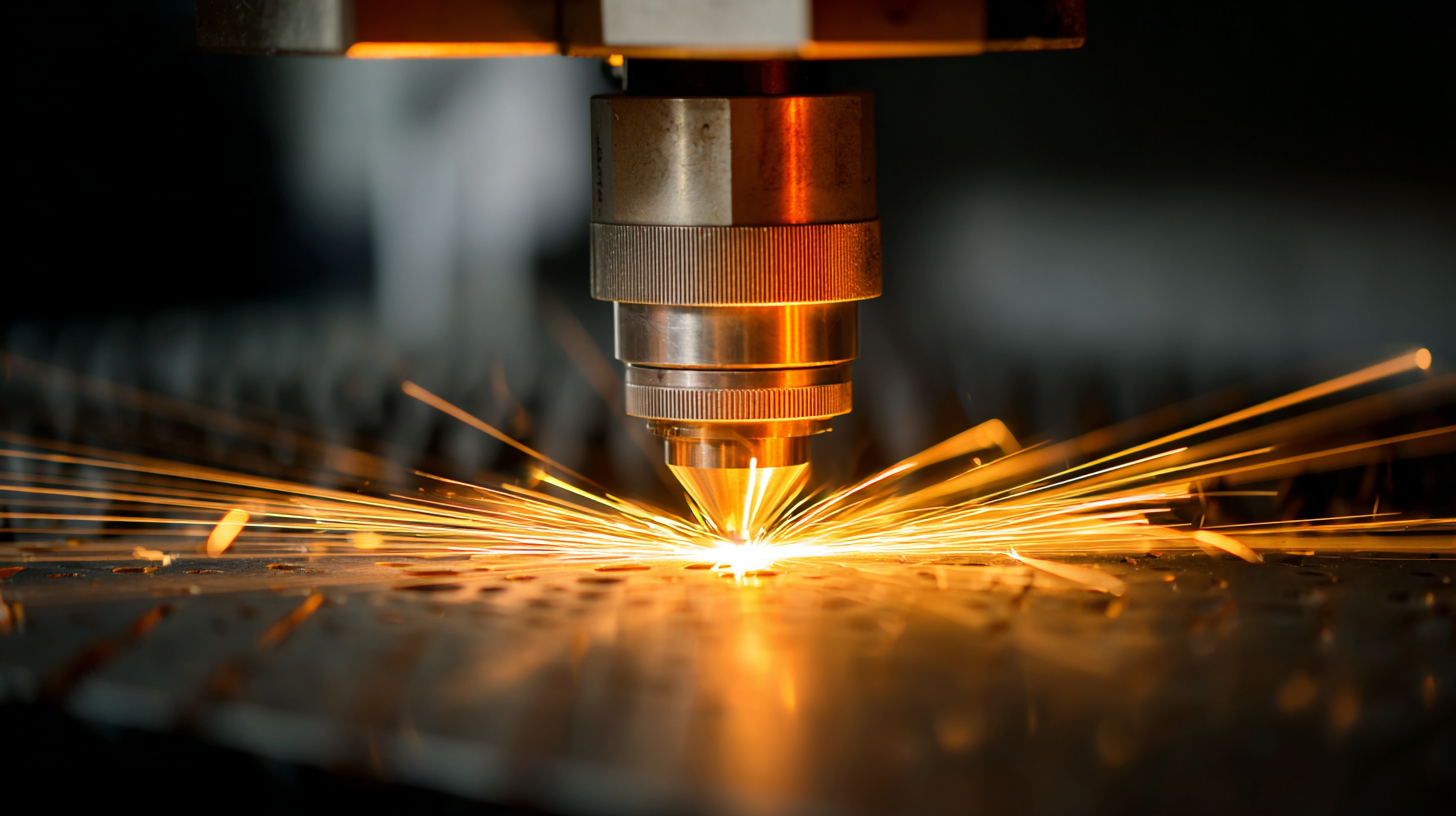

When it comes to jewelry welding, understanding fiber laser technology is crucial for making informed decisions on machinery. Fiber lasers have revolutionized the welding process, offering high precision and efficiency, particularly suited for delicate materials often used in jewelry making. The strength and focus of fiber lasers allow them to produce clean and precise welds, which is essential for maintaining the visual appeal and quality of the finished pieces. As the global demand for laser welding machines continues to rise—projected to grow significantly from USD 2.9 billion in 2025 to USD 4.5 billion by 2034—investing in a fiber laser welding machine can be a game-changer for jewelers.

Recent advancements in multi-beam technology further enhance the cost efficiency of fiber laser welding machines. This innovation allows multiple laser beams to work simultaneously, increasing throughput and reducing production time. For businesses looking to streamline their operations while maintaining top-notch quality, this technology represents a significant competitive advantage. Companies like Maven Laser Automation Co., Ltd. are at the forefront of developing these systems, ensuring that jewelers have access to the latest technology tailored to their specific needs, from design to the final production phase. As the market evolves, staying informed about these advancements will empower jewelers to choose the right equipment for their craft.

Key Features to Look for in a Fiber Laser Welding Machine

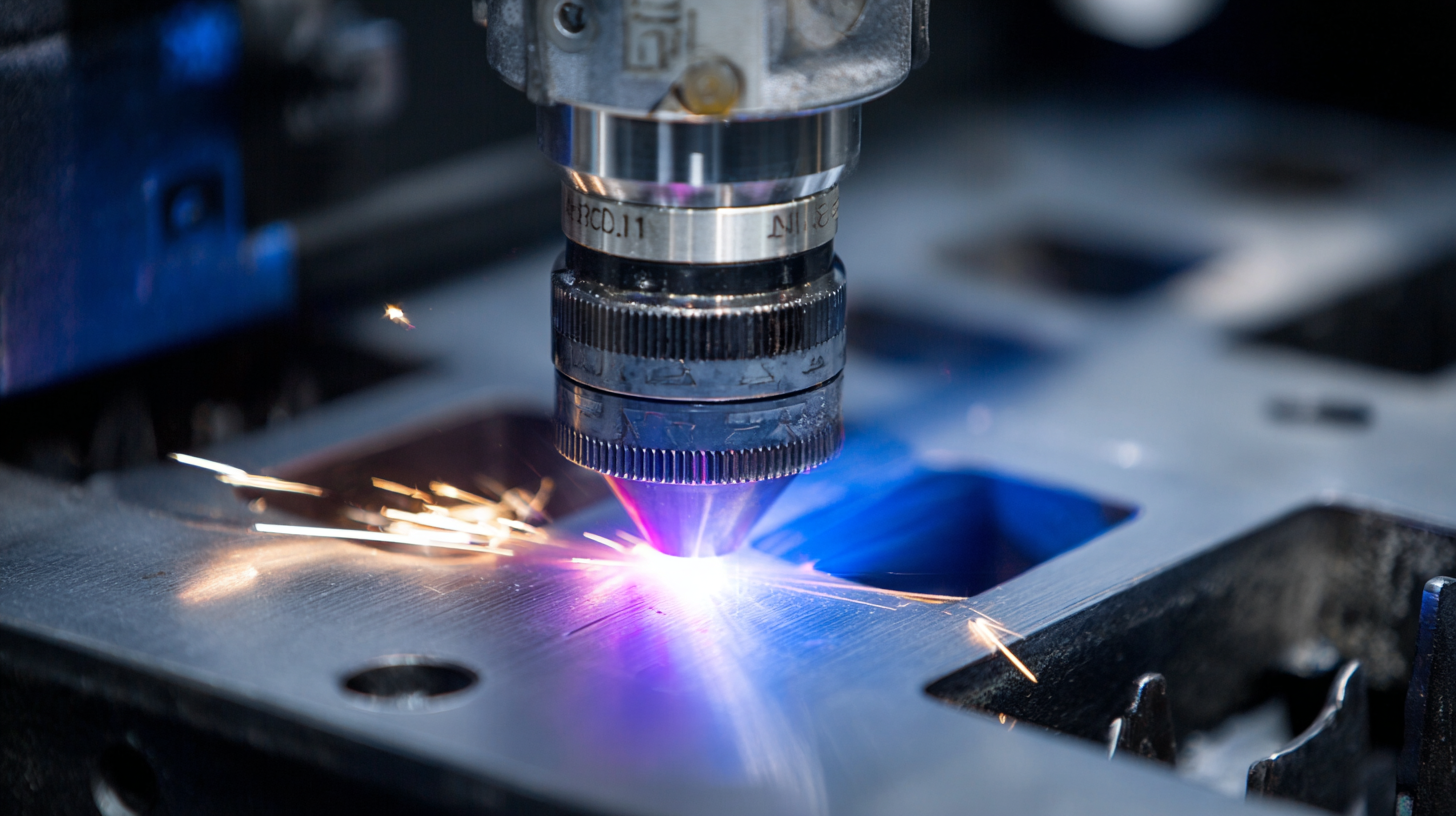

When selecting the best fiber laser welding machine for jewelry, it's essential to focus on key features that enhance performance and compatibility with various tasks. Fiber lasers offer distinct advantages, including superior beam quality, remarkable precision, and exceptional energy efficiency. According to industry reports, fiber lasers can achieve up to 90% efficiency compared to traditional laser systems, making them ideal for intricate jewelry applications where detail is paramount.

Tips: When evaluating fiber laser welding machines, consider the wavelength, as it affects material interaction. A wavelength around 1064 nm is preferable for metals, ensuring optimal absorption and minimal thermal distortion. Additionally, look for machines with adjustable pulse duration and power settings to accommodate different materials and thicknesses.

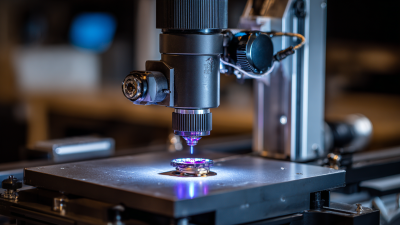

It's also crucial to assess the machine's cooling system and portability. Efficient cooling systems help maintain consistent performance during prolonged use, while a compact design can benefit both hobbyists and professionals. Investing in a machine like the latest X1 Pro model, designed for versatility in welding, cutting, and cleaning tasks, ensures that it meets a wide range of jewelry-making needs efficiently.

Top Brands and Models of Fiber Laser Welders for Jewelers

When selecting a fiber laser welding machine for jewelry, it's essential to consider top brands and models that cater specifically to the needs of jewelers. According to a recent report by Research and Markets, the global fiber laser market is projected to grow at a CAGR of 9.3% through 2027, highlighting the increasing adoption of this technology across various industries. Leading manufacturers like Trumpf, IPG Photonics, and Han's Laser are recognized for their advanced fiber laser systems, which offer precision and versatility, crucial for intricate jewelry designs.

For jewelers, models such as the Trumpf TruLaser 1040 and the IPG Photonics LightWELD 150 provide excellent features that enhance productivity and quality. The TruLaser series is known for its user-friendly interface and exceptional speed, allowing jewelers to weld delicate pieces without compromising structural integrity. Meanwhile, the LightWELD system incorporates innovative cooling technology, which maintains low heat input, thereby preserving the finish of fine jewelry. These brands set the standard in the industry, ensuring that jewelers can achieve superior results with their laser welding operations.

Ultimate Guide to Choosing the Best Fiber Laser Welding Machine for Jewelry

| Model | Wattage | Max Welding Thickness | Welding Speed | Cooling System | Weight | Price Range |

|---|---|---|---|---|---|---|

| Model A | 100W | 1.5 mm | 50 mm/s | Water Cooling | 60 kg | $3,000 - $4,500 |

| Model B | 200W | 2 mm | 70 mm/s | Air Cooling | 75 kg | $5,000 - $6,800 |

| Model C | 300W | 2.5 mm | 90 mm/s | Chiller Cooling | 80 kg | $7,000 - $9,000 |

| Model D | 400W | 3 mm | 100 mm/s | Water Cooling | 95 kg | $10,000 - $12,500 |

Cost vs. Performance: What to Expect from Fiber Laser Welding Machines

When it comes to selecting the ideal fiber laser welding machine for jewelry, understanding the balance between cost and performance is crucial. According to a report by MarketsandMarkets, the global fiber laser market is expected to reach $2 billion by 2025, driven by increasing applications in precision manufacturing. For jewelry makers, investing in a high-quality fiber laser welding machine can significantly enhance the quality of welds, reduce material waste, and improve overall production efficiency.

Performance parameters such as laser power, speed, and precision are vital. A machine offering at least 100 to 200 watts of laser power is generally recommended for jewelry applications, as it provides enough intensity to handle various metals, including gold and silver, with minimal heat distortion. Also, consider that machines with higher efficiency can reduce operational costs in the long run. For instance, a well-optimized fiber laser welding machine can save up to 30% in energy consumption compared to traditional welding methods, thus providing a compelling argument for higher upfront investments.

Maintenance Tips for Longevity of Your Fiber Laser Welder

When investing in a fiber laser welding machine for jewelry production, maintenance is crucial to ensure longevity and optimal performance. According to a report by the International Laser Manufacturing Society, proper maintenance can extend the lifespan of laser machines by up to 30%. Regularly scheduled servicing, including cleaning the optics and checking the cooling system, can prevent overheating and ensure consistent welding quality.

Moreover, using high-quality consumables and following the manufacturer’s guidelines can significantly reduce wear and tear. A study published in the Journal of Laser Applications indicates that machines that adhere to routine maintenance schedules experience lower failure rates—often saving manufacturers up to 20% in annual repair costs. Keeping the fiber cable free from contamination and ensuring that the machine operates in a stable environment can further enhance its reliability, allowing jewelers to produce intricate designs with precision while maximizing their investment in technology.

Common Applications of Fiber Laser Welding in Jewelry Making

In the jewelry-making industry, fiber laser welding machines have become increasingly vital for creating intricate designs with precision and efficiency. One of the most common applications of these advanced machines is in the crafting of delicate jewelry pieces where heat control is crucial. The laser's capability to produce focused energy enables jewelers to join metals without affecting the surrounding materials, resulting in cleaner, more aesthetically pleasing joints. This application is particularly beneficial in the assembly of intricate components, such as settings for gemstones, where structural integrity and visual quality are paramount.

In the jewelry-making industry, fiber laser welding machines have become increasingly vital for creating intricate designs with precision and efficiency. One of the most common applications of these advanced machines is in the crafting of delicate jewelry pieces where heat control is crucial. The laser's capability to produce focused energy enables jewelers to join metals without affecting the surrounding materials, resulting in cleaner, more aesthetically pleasing joints. This application is particularly beneficial in the assembly of intricate components, such as settings for gemstones, where structural integrity and visual quality are paramount.

Moreover, the market for laser welding machines is witnessing significant growth, valued at USD 2.7 billion in 2024, with projections to reach USD 4.5 billion by 2034. This growth is driven by an increasing demand for automation and precision in manufacturing, coupled with the rising trend of bespoke jewelry designs. Robotic and laser welding technologies are not only streamlining production processes but also enhancing customization capabilities in jewelry making. As these technologies advance, traditional craftsmanship is being augmented, allowing jewelers to push the boundaries of design while maintaining high standards of quality and efficiency.

FAQS

: Fiber laser technology is a welding method that utilizes highly focused laser beams to produce clean and precise welds, making it particularly suitable for the delicate materials often used in jewelry making. It offers high precision, efficiency, and helps maintain the visual appeal and quality of finished pieces.

The global demand for laser welding machines is expected to grow significantly, with projections increasing from USD 2.9 billion in 2025 to USD 4.5 billion by 2034.

Multi-beam technology allows multiple laser beams to work simultaneously, which increases throughput and reduces production time, enhancing cost efficiency and providing a competitive advantage for businesses.

Important features to consider include beam quality, precision, energy efficiency, adjustable pulse duration and power settings, as well as the machine’s cooling system and portability.

The wavelength affects how materials interact with the laser. A wavelength around 1064 nm is preferable for metals, as it ensures optimal absorption and minimizes thermal distortion during the welding process.

Fiber lasers can achieve up to 90% efficiency, making them ideal for intricate applications in jewelry making where detail is critical.

An efficient cooling system helps maintain consistent performance during prolonged use, which is vital for ensuring high-quality welds and prolonging the machine's lifespan.

The X1 Pro model is designed for versatility in welding, cutting, and cleaning tasks, making it suitable for a wide range of jewelry-making needs efficiently.

Staying informed about technological advancements enables jewelers to make informed decisions when investing in equipment, ensuring they select the right tools to enhance their craft and improve operational efficiency.

Conclusion

When choosing a Fiber Laser Welding Machine for Jewelry, it's essential to understand the underlying technology and its benefits for precision welding. Fiber lasers offer superior beam quality and efficiency, making them ideal for intricate jewelry designs. Key features to consider include welding speed, the range of power settings, and user-friendly controls. Popular brands like Maven Laser Automation Co., Ltd., known for its innovation and quality in laser systems since 2008, provide trusted options.

Additionally, while evaluating the cost versus performance, one should consider not only the initial investment but also long-term operational costs. Proper maintenance is crucial for maximizing the lifespan and functionality of your welding machine. With a clear understanding of common applications in jewelry making, jewelers can make informed decisions to enhance their craftsmanship and production efficiency with the best Fiber Laser Welding Machine for Jewelry.

Related Posts

-

Ultimate Guide to Mastering the 200w Jewelry Spot Welder for Perfect Joints

-

5 Reasons Why the Portable Pulse Laser Cleaner is Essential for Modern Manufacturing

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

How to Select the Best Fiber Laser Cutting Machine Manufacturers: Key Industry Insights

-

Discover the Finest Laser Cleaner: Premium Quality from China's Leading Manufacturing Factory

-

How to Choose the Best 100w Fiber Laser Engraving Machine for Your Business

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top