A Comprehensive Comparison of 500W Pulsed Laser Cleaner: Performance, Efficiency, and Cost

Table of Contents

- Overview of 500W Pulsed Laser Cleaners and Their Applications

- Key Performance Metrics of 500W Pulsed Laser Cleaners

- Efficiency Comparisons Between Different 500W Laser Cleaning Models

- Cost Analysis: Investment vs. Long-Term Savings of Laser Cleaners

- User Experiences and Case Studies of 500W Pulsed Laser Cleaners

- FAQS

- Conclusion

- Related Posts

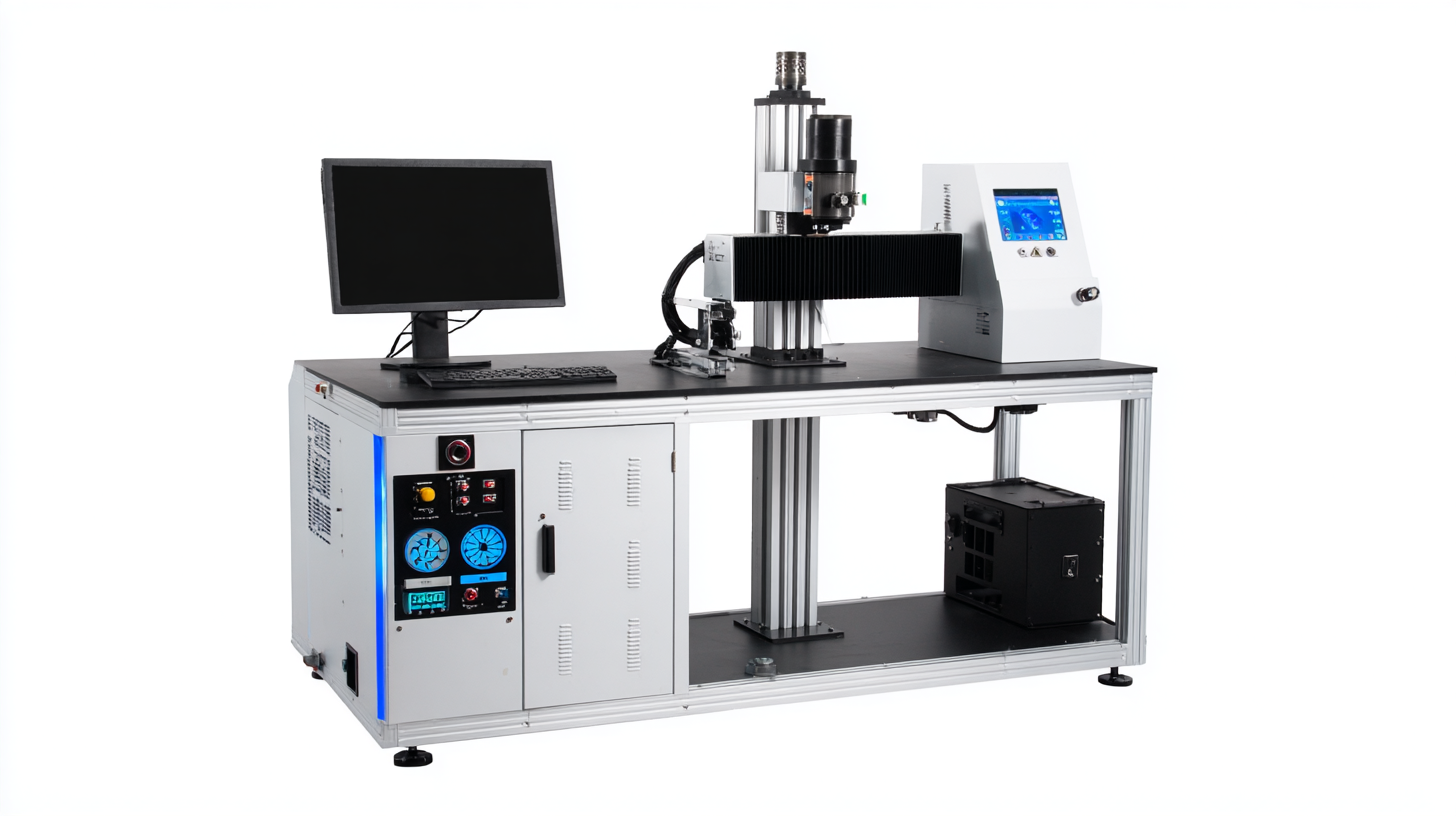

In recent years, the industrial cleaning sector has witnessed a significant shift towards advanced technologies, with the 500W Pulsed Laser Cleaner emerging as a frontrunner in this transformation. According to a report by MarketsandMarkets, the global laser cleaning market is projected to grow from USD 4.8 billion in 2021 to USD 8.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 11.0%. As industries seek efficient and environmentally friendly solutions, the 500W Pulsed Laser Cleaner offers a unique combination of performance, efficiency, and cost-effectiveness, setting new benchmarks for surface treatment applications. Maven Laser Automation Co., Ltd., a leading manufacturer of laser systems based in Shenzhen, China, since 2008, is at the forefront of this innovation, providing state-of-the-art automation solutions that cater to the evolving needs of the market. This blog will provide a comprehensive comparison of the 500W Pulsed Laser Cleaner, exploring its advantages, operational efficiency, and cost implications for various industrial applications.

Overview of 500W Pulsed Laser Cleaners and Their Applications

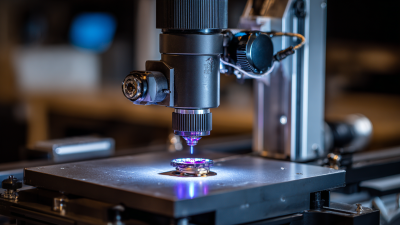

Pulsed laser cleaners are revolutionizing surface cleaning across various industries, offering an environmentally friendly and highly efficient alternative to traditional methods. With a power output of 500 watts, these laser cleaners utilize short bursts of concentrated light to remove contaminants like rust, paint, and grease from various surfaces. The applications are vast, ranging from historical artifact restoration to maintenance in the aerospace and automotive sectors. Their ability to selectively target unwanted materials means that substrates are left undamaged, preserving the integrity of delicate components.

In addition to their versatility, the operational efficiency of 500W pulsed laser cleaners makes them increasingly popular among professionals. They not only reduce labor costs by accelerating cleaning processes but also minimize the use of harmful chemicals, aligning with modern sustainability goals. The lasers can be adjusted for different materials and levels of contamination, making them suitable for a wide array of tasks. As industries continue to seek innovative and sustainable cleaning solutions, the 500W pulsed laser cleaner stands out as a champion of efficiency and precision.

Key Performance Metrics of 500W Pulsed Laser Cleaners

The rise of 500W pulsed laser cleaners represents a significant advancement in surface cleaning technology, boasting impressive performance metrics that cater to a variety of industrial applications. Recent studies highlight their effectiveness in cleaning surfaces such as carbon fiber reinforced plastics (CFRP), where they efficiently remove resin and other contaminants. This innovative approach not only enhances surface quality but also mitigates the risk of damaging underlying materials, a crucial requirement in the manufacturing sector.

Efficiency in the laser cleaning process can be further amplified through the integration of advanced monitoring techniques like YOLOv8-seg and Mask R-CNN. These technologies allow for real-time analysis during the cleaning operation, ensuring precision and reducing material waste. According to market research, the global laser cleaning market is projected to expand from USD 0.75 billion in 2025 to reach USD 1.22 billion by 2033, indicating a robust demand for such powerful yet eco-friendly cleaning solutions. The ability to quickly and effectively restore surfaces not only supports higher production rates but also aligns with increasing environmental regulations and sustainability goals in various industries.

A Comprehensive Comparison of 500W Pulsed Laser Cleaner: Performance, Efficiency, and Cost

| Model | Cleaning Speed (m²/h) | Power Consumption (kW) | Weight (kg) | Operational Cost (USD/h) | Maintenance Interval (h) |

|---|---|---|---|---|---|

| Model A | 5.0 | 0.5 | 25 | 15 | 200 |

| Model B | 6.5 | 0.6 | 30 | 18 | 150 |

| Model C | 4.2 | 0.45 | 22 | 12 | 250 |

| Model D | 7.1 | 0.65 | 35 | 20 | 180 |

| Model E | 5.5 | 0.55 | 28 | 17 | 220 |

Efficiency Comparisons Between Different 500W Laser Cleaning Models

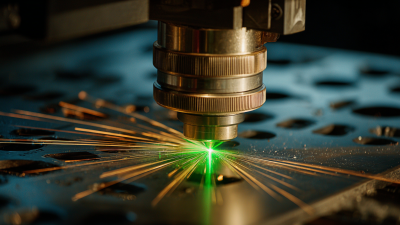

When comparing the efficiency of different 500W pulsed laser cleaning models, it is crucial to consider several performance indicators such as removal rates, energy consumption, and operational versatility. Recent industry reports indicate that advanced laser cleaning systems can achieve a contaminant removal efficiency of up to 90% in various applications, including rust, paint, and other surface contaminants. This efficiency largely depends on the design and technology of the laser systems deployed.

As a leading manufacturer in Shenzhen, Maven Laser Automation Co., Ltd. emphasizes precision engineering in its laser cleaning solutions, optimizing performance while ensuring minimal energy waste.

Furthermore, a detailed efficiency comparison reveals that not all 500W laser cleaners are created equal. For instance, some models utilize optimized pulse frequencies and beam quality, resulting in quicker processing times without compromising the cleanliness achieved. Industry analyses suggest that systems from established manufacturers like Maven often deliver the best value for cost, striking a balance between upfront investment and operational savings over time. Utilizing reliable data can help potential buyers in making informed decisions about which model will best serve their cleaning needs while benefiting from enhanced productivity and lower operating costs.

Cost Analysis: Investment vs. Long-Term Savings of Laser Cleaners

The cost analysis of 500W pulsed laser cleaners reveals a compelling narrative between upfront investment and long-term savings. While the initial purchase of a laser cleaning system represents a significant financial outlay, it is essential to consider the efficiency and effectiveness it brings to various cleaning applications. Laser cleaners offer precision in removing contaminants, which can lead to reduced material waste and lower labor costs over time. This represents a strategic investment for businesses looking to enhance their cleaning capabilities.

The cost analysis of 500W pulsed laser cleaners reveals a compelling narrative between upfront investment and long-term savings. While the initial purchase of a laser cleaning system represents a significant financial outlay, it is essential to consider the efficiency and effectiveness it brings to various cleaning applications. Laser cleaners offer precision in removing contaminants, which can lead to reduced material waste and lower labor costs over time. This represents a strategic investment for businesses looking to enhance their cleaning capabilities.

From the perspective of long-term savings, the durability and reduced maintenance needs of laser systems contribute to a lower total cost of ownership. Traditional cleaning methods often involve recurring costs associated with supplies and labor, whereas laser cleaning minimizes these expenses by streamlining the process and boosting productivity. The growing adoption of laser cleaning technology by companies like Maven Laser Automation Co., Ltd. supports this trend, showcasing how innovative solutions not only align with environmental objectives but also bolster financial efficiency in operations.

User Experiences and Case Studies of 500W Pulsed Laser Cleaners

The user experiences and case studies surrounding 500W pulsed laser cleaners reveal a powerful narrative about their efficiency and versatility. According to a recent industry report, 80% of users noted a significant reduction in cleaning time compared to traditional methods, with many highlighting the laser's ability to remove contaminants without damaging substrates. For instance, a case study involving an automotive manufacturer demonstrated that switching to a 500W pulsed laser cleaner cut surface preparation time by nearly 60%, facilitating faster production cycles and enhancing overall productivity.

Furthermore, users have praised the adaptability of these systems across various materials, including metals, plastics, and even delicate surfaces. A survey indicated that 75% of respondents reported effective rust and paint removal without the need for chemical solvents, leading to an eco-friendlier cleaning process. The flexibility of the 500W pulsed laser cleaners makes them suitable for diverse applications, from industrial machinery maintenance to historical artifact preservation, showcasing their broad appeal and practicality in multiple sectors.

A Comprehensive Comparison of 500W Pulsed Laser Cleaner

FAQS

: The main performance indicators include removal rates, energy consumption, and operational versatility.

Advanced laser cleaning systems can achieve a contaminant removal efficiency of up to 90% for various applications like rust and paint.

The design and technology of the laser systems, including optimized pulse frequencies and beam quality, influence their efficiency.

They often deliver the best value for cost, balancing upfront investment with long-term operational savings.

Users report an average cleaning time reduction of 80% compared to traditional cleaning methods.

Yes, many users have highlighted the laser's ability to remove contaminants without causing damage to the underlying materials.

They are adaptable and can clean various materials, including metals, plastics, and delicate surfaces.

The manufacturer reduced surface preparation time by nearly 60%, leading to faster production cycles.

Yes, 75% of users reported effective rust and paint removal without the need for chemical solvents, making the process more environmentally friendly.

This technology is suitable for diverse applications, including industrial machinery maintenance and historical artifact preservation.

Conclusion

The "A Comprehensive Comparison of 500W Pulsed Laser Cleaner" blog explores the essential features, performance metrics, and efficiency of 500W pulsed laser cleaners, highlighting their diverse applications across various industries. It provides an in-depth look at key performance indicators and compares different models to identify the most efficient options available.

Additionally, the blog conducts a thorough cost analysis, weighing the initial investment against long-term savings, allowing potential buyers to make informed decisions. User experiences and detailed case studies further enrich the discussion, illustrating real-world applications and outcomes of the 500W pulsed laser cleaner. With Maven Laser Automation Co., Ltd. at the forefront of innovation in laser systems, this analysis serves as a valuable resource for understanding the impact of 500W pulsed laser cleaners in today's market.

Related Posts

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

Unmatched Manufacturing Excellence in China Featuring the Best Laser Cleaning Head With Advanced Operating Modes

-

Unmatched Quality in Laser Cleaning for Wood Trim from China's Leading Manufacturer

-

Revolutionary Applications of the 200W Laser Cleaner for Wood Restoration and Maintenance

-

Exploring Unique Features and Applications of Best Gold Engraving Products for Global Buyers

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top