5 Effective Rust Removalaser Strategies to Enhance Your Industrial Efficiency

Table of Contents

- Understanding the Impact of Rust on Industrial Equipment Performance

- Top Strategies for Identifying Rust in Your Industrial Operations

- Best Practices for Preventing Rust Formation in Industrial Settings

- Innovative Rust Removal Techniques to Boost Productivity

- Integrating Regular Maintenance to Combat Rust Issues Effectively

- FAQS

- Conclusion

- Related Posts

In the competitive landscape of industrial efficiency, rust removal plays a crucial role in maintaining equipment longevity and operational effectiveness. According to a recent market analysis, the global rust removal market is projected to reach $1.5 billion by 2025, highlighting the increasing demand for effective solutions in various sectors.

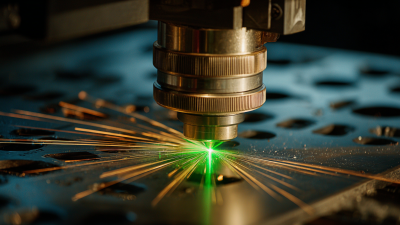

One innovative approach that has gained traction is the use of Rust Removalaser technology, which leverages precision lasers to eliminate corrosion without damaging underlying materials. Maven Laser Automation Co., Ltd., a leading manufacturer of laser systems and professional automation solutions since 2008, has positioned itself at the forefront of this technological advancement. Located in Shenzhen, China, Maven Laser specializes in creating tailored solutions that not only enhance rust removal processes but also improve overall industrial efficiency.

This blog will explore five effective strategies utilizing Rust Removalaser technology to transform your operations and drive maximum productivity.

Understanding the Impact of Rust on Industrial Equipment Performance

Rust is more than just an aesthetic issue for industrial equipment; it significantly affects performance and operational efficiency. When rust develops on machinery, it leads to increased friction, reduced productivity, and can even result in catastrophic failures. Understanding how rust impacts your equipment is crucial in maintaining optimal functionality and prolonging the lifespan of assets.

To combat the detrimental effects of rust, implementing effective rust removal strategies is essential. One vital tip is to conduct regular inspections and maintenance, as catching rust in its early stages can prevent extensive damage. Furthermore, utilizing protective coatings can create a barrier between metal surfaces and moisture, significantly reducing the likelihood of rust formation.

Another approach is to ensure proper storage conditions for equipment, such as maintaining low humidity levels and shielding machinery from rain or excess moisture. Additionally, adopting a routine cleaning regimen using rust inhibitors can be beneficial in preserving the integrity of equipment and enhancing overall industrial efficiency. Empowering your maintenance team with these strategies will drive performance improvements and ultimately lead to cost savings.

Top Strategies for Identifying Rust in Your Industrial Operations

In industrial operations, identifying rust is crucial to maintaining equipment efficiency and safety. Early detection of rust can significantly reduce repair costs and operational downtime. Implementing effective inspection routines can help pinpoint areas vulnerable to rust formation. Regular visual inspections should be conducted to catch signs of discoloration or flaking, which are early indicators of rust.

Moreover, incorporating technology like ultrasonic thickness gauges can provide precise measurements of corrosion levels. These tools can detect rust beneath coatings, ensuring that hidden issues are addressed before they escalate. Establishing a routine maintenance schedule that includes these inspections can lead to more reliable equipment performance and extended lifespan.

Another tip is to promote a culture of awareness among staff regarding the signs of rust. Training team members to recognize and report potential rust formation can facilitate swift intervention, enhancing overall efficiency. Additionally, utilizing moisture control methods, such as dehumidifiers, can create an environment less conducive to rust development, further protecting valuable machinery.

Best Practices for Preventing Rust Formation in Industrial Settings

In industrial settings, preventing rust formation is crucial for maintaining equipment efficiency and longevity. One effective tip for prevention is to ensure regular maintenance of machinery and tools. By conducting routine inspections and applying protective coatings, you can significantly reduce the likelihood of rust developing on metal surfaces.

Additionally, creating a clean work environment free from moisture and contaminants will help keep rust at bay.

Another best practice involves the use of advanced protective materials. Implementing choices like stainless steel or galvanized metal in your equipment design can provide a natural resistance to corrosion. Moreover, consider using rust inhibitors in your cleaning processes, as these chemicals can create a protective barrier that prevents moisture from reaching the metal's surface.

Lastly, incorporating climate control measures in your industrial space can play a vital role in rust prevention. Maintaining optimal humidity levels and ensuring proper ventilation can drastically diminish the conditions conducive to rust formation. By following these strategies, you can enhance your industrial efficiency and extend the lifespan of your machinery.

Innovative Rust Removal Techniques to Boost Productivity

In today’s industrial landscape, rust removal plays a critical role in maintaining equipment efficiency and prolonging asset lifespan. Innovative rust removal techniques have been shown to significantly boost productivity in manufacturing environments. According to a report by the NACE International Institute, corrosion costs U.S. industries approximately $279 billion annually, underscoring the need for effective rust management strategies. Implementing advanced rust removal methods not only reduces downtime but also enhances operational efficiency.

One of the most effective strategies involves the utilization of eco-friendly rust removers that minimize environmental impact while delivering strong results. A study from the American Coatings Association indicated that biodegradable rust removal solutions can achieve efficiency rates of up to 95%, compared to traditional methods. Additionally, automated blasting techniques that streamline the rust removal process can result in 30% faster cleaning times, leading to a quicker turnaround in production cycles. By integrating these innovative techniques, industries can achieve substantial improvements in output while safeguarding their equipment from the detrimental effects of rust.

5 Effective Rust Removal Strategies to Enhance Your Industrial Efficiency

Integrating Regular Maintenance to Combat Rust Issues Effectively

Rust can pose a significant threat to industrial efficiency, leading to costly repairs and downtime. To effectively combat rust issues, integrating regular maintenance into your operational routine is crucial. Establishing a systematic maintenance schedule allows for early detection of rust formation, enabling teams to address potential problems before they escalate. Routine inspections of machinery and tools can help identify vulnerable areas, while cleaning and protective coatings can be applied to mitigate corrosion risks.

In addition to scheduled maintenance, employee training is essential to ensure that staff are aware of rust prevention strategies. Empowering your workforce with the knowledge of proper handling and storage techniques can significantly reduce rust occurrences. Furthermore, utilizing advanced materials and rust-resistant coatings can offer an extra layer of protection, enhancing the longevity of equipment. By prioritizing regular maintenance and fostering a culture of awareness around rust prevention, industries can boost their efficiency, minimize operation interruptions, and ultimately save money in the long run.

FAQS

: Identifying rust is crucial because early detection can significantly reduce repair costs and operational downtime, ensuring equipment efficiency and safety.

Signs of discoloration or flaking on metal surfaces are early indicators of rust that should be caught during regular visual inspections.

Ultrasonic thickness gauges provide precise measurements of corrosion levels and can detect rust beneath coatings, allowing for the identification of hidden issues.

A routine maintenance schedule should include regular visual inspections and the use of technology such as ultrasonic thickness gauges to monitor equipment conditions.

Training team members to recognize and report signs of rust can facilitate swift intervention, improving overall efficiency and minimizing damage.

Utilizing moisture control methods, such as dehumidifiers, can create an environment less conducive to rust development, protecting valuable machinery.

Applying protective coatings during routine maintenance can significantly reduce the likelihood of rust developing on metal surfaces.

Using advanced materials like stainless steel or galvanized metal in equipment design provides natural resistance to corrosion, helping to prevent rust formation.

Maintaining a clean work environment free from moisture and contaminants is essential to keeping rust at bay.

Maintaining optimal humidity levels and ensuring proper ventilation can drastically reduce conditions that are conducive to rust formation.

Conclusion

In today's industrial landscape, addressing rust formation is crucial for maintaining equipment performance and enhancing overall productivity. Our blog, "5 Effective Rust Removalaser Strategies to Enhance Your Industrial Efficiency," explores the significant impact of rust on industrial operations and provides actionable insights to combat this pervasive issue. We discuss top strategies for identifying rust early, best practices for prevention, and innovative rust removal techniques utilizing cutting-edge Rust Removalaser technology that can significantly boost operational efficiency.

Additionally, we emphasize the importance of integrating regular maintenance practices to effectively combat rust issues. With a focus on solutions provided by Maven Laser Automation Co., Ltd., as a leader in laser systems and automation solutions, our strategies aim to equip industries with the necessary tools to minimize downtime and maximize productivity. Implementing these strategies will not only improve equipment longevity but also ensure a smoother operational workflow in your industrial settings.

Related Posts

-

Comprehensive Solutions for Efficient Rust Removal with the Best 3000W 4-In-1 Laser Cleaning Machine

-

5 Essential Tips for Using Pulse Laser Cleaning Machine for Rust Removal

-

Revolutionary Applications of the 200W Laser Cleaner for Wood Restoration and Maintenance

-

Mastering Laser Welder Cutter Cleaner Techniques for Optimal Performance and Efficiency in Your Workshop

-

7 Best Reasons to Invest in a Rust Cleaning Laser Machine

-

The Future of Affordable Laser Machine Price Innovations

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top