How to Effectively Use Portable 1000w Laser Cleaner for Industrial Applications

Table of Contents

- Understanding the Basics of Portable 1000w Laser Cleaners

- Key Benefits of Using Laser Cleaning Technology in Industry

- Essential Safety Precautions When Operating a Laser Cleaner

- Step-by-Step Guide to Setting Up Your Portable Laser Cleaner

- Maintenance Tips for Ensuring Longevity of Your Laser Cleaning Equipment

- Common Applications of 1000w Laser Cleaners in Various Industries

- FAQS

- Conclusion

- Related Posts

The growing demand for efficient and eco-friendly cleaning solutions in industrial environments has led to the emergence of advanced technologies, with the Portable 1000w Laser Cleaner standing out in the market. According to a recent report by MarketsandMarkets, the laser cleaning industry is expected to reach a market size of USD 1.3 billion by 2025, driven by the rising need for precise and non-destructive cleaning techniques. As businesses prioritize sustainability and operational efficiency, the Portable 1000w Laser Cleaner offers a versatile solution that can easily adapt to various applications, providing effective rust removal, paint stripping, and surface preparation. Established in 2008, Maven Laser Automation Co., Ltd. is at the forefront of this technological evolution, manufacturing innovative laser systems and professional automation solutions that cater to the dynamic needs of the industry, solidifying its position as a leader in the laser market since its inception.

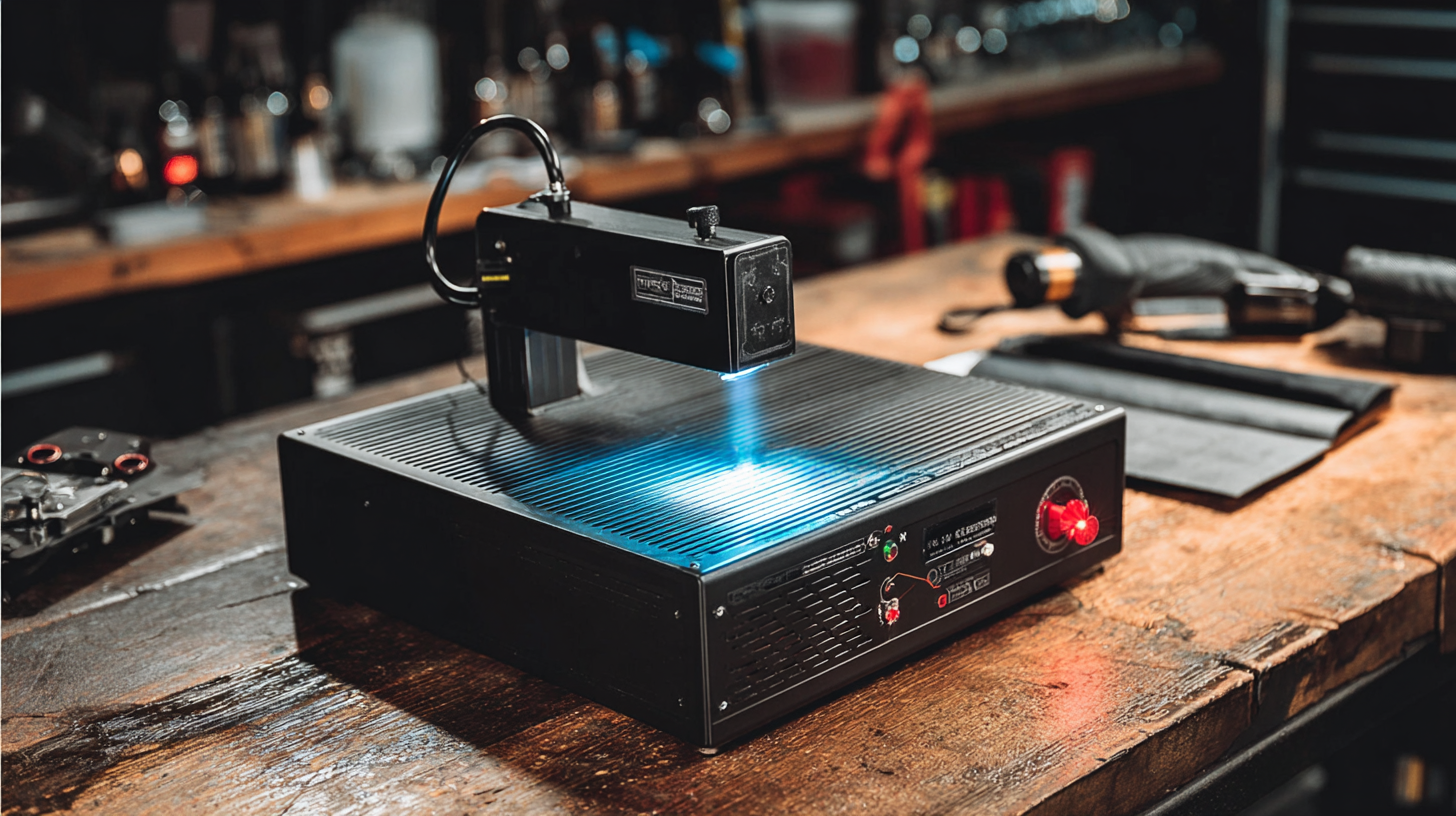

Understanding the Basics of Portable 1000w Laser Cleaners

Portable 1000w laser cleaners are transforming industrial cleaning processes, offering a non-contact solution that is not only effective but also environmentally friendly. These devices utilize focused laser beams to remove contaminants such as rust, paint, and pollutants from various surfaces. According to industry reports, the market for laser cleaning technology is expected to grow significantly, projecting a compound annual growth rate (CAGR) of around 10% over the next five years. This growth is attributed to the rising demand for efficient and eco-friendly cleaning solutions in manufacturing, automotive, and aerospace sectors.

Understanding the basics of how these portable units operate is crucial for optimizing their use. The 1000w power output allows for effective cleaning while minimizing surface damage, a critical factor when dealing with delicate components. Moreover, portable laser cleaners can be easily maneuvered, addressing hard-to-reach areas without the need for excessive equipment or setup time. Recent analyses highlight that using such systems can reduce cleaning times by up to 75% compared to traditional methods, translating to significant labor cost savings and enhanced productivity for industrial operations.

How to Effectively Use Portable 1000w Laser Cleaner for Industrial Applications

| Application | Material | Cleaning Time (min) | Power Consumption (kw) | Advantages |

|---|---|---|---|---|

| Rust Removal | Steel | 5 | 1.0 | Eco-friendly, fast processing |

| Paint Stripping | Aluminum | 8 | 1.0 | No chemical waste, high precision |

| Surface Preparation | Titanium | 10 | 1.0 | Improves adhesion, clean finish |

| Graffiti Removal | Concrete | 6 | 1.0 | Non-abrasive, no surface damage |

| Weld Spatter Removal | Stainless Steel | 4 | 1.0 | Enhances aesthetic, quick cleanup |

Key Benefits of Using Laser Cleaning Technology in Industry

The integration of laser cleaning technology in industrial applications has revolutionized the way manufacturers approach surface preparation and maintenance. One of the significant advantages of using a portable 1000w laser cleaner is its ability to remove contaminants from surfaces without the need for harsh chemicals or additional abrasives. According to a report by MarketsandMarkets, the global laser cleaning market is expected to reach USD 1.07 billion by 2025, driven primarily by the increasing demand for environmentally friendly cleaning solutions in various sectors, including aerospace, automotive, and heritage conservation.

Maven Laser Automation Co., Ltd., a leading manufacturer based in Shenzhen, China, has been at the forefront of this technological advancement since its establishment in 2008. Their portable 1000w laser cleaners not only enhance cleaning efficiency but also reduce downtime, as they can easily be maneuvered in various settings. Studies show that laser cleaning can improve productivity by up to 30% compared to traditional cleaning methods. With the potential to minimize ecological impact, organizations can meet sustainability goals while optimizing their operations. The versatility and effectiveness of laser cleaning make it an increasingly important tool in modern industrial processes.

Essential Safety Precautions When Operating a Laser Cleaner

Operating a portable 1000w laser cleaner in industrial applications can greatly enhance efficiency and precision in cleaning processes. However, safety must remain a top priority when working with such powerful equipment. Before starting, ensure that all operators are adequately trained in laser safety protocols. This includes wearing appropriate personal protective equipment (PPE) such as safety goggles, gloves, and protective clothing to shield against potential hazards. Additionally, it is crucial to establish a clear operational zone, marking areas where the laser may be in use and keeping unauthorized personnel at a safe distance.

At Maven Laser Automation Co., Ltd., we emphasize the importance of safety in every aspect of our laser systems. With over a decade of experience in the laser market, we are dedicated to designing robust and safe laser solutions tailored to industrial needs. Operators should conduct a thorough risk assessment before commencing work and maintain awareness of the laser's operational mechanics. Regular maintenance checks are also essential to ensure that safety features are functioning correctly, further minimizing risks associated with the use of portable laser cleaners. By adhering to these safety precautions, users can effectively leverage the power of laser technology while maintaining a secure working environment.

Step-by-Step Guide to Setting Up Your Portable Laser Cleaner

Setting up a portable 1000w laser cleaner for industrial applications can greatly enhance efficiency and cleaning precision. To begin, ensure you have a clean, well-lit workspace. Position the machine on a stable surface and check that all safety features, such as emergency stops and safety goggles, are in place. A survey by the International Journal of Advanced Manufacturing Technology indicates that using laser cleaning can reduce cleaning time by up to 90% compared to conventional methods, making the right setup essential for achieving optimal results.

When connecting the laser cleaner, follow the manufacturer’s guidelines carefully. Ensure that the power supply is suitable and that all connections are secure. It’s advisable to practice controlling the laser with a focus on the distance and speed adjustments, as variations can significantly affect cleaning outcomes. According to a study from the Society of Manufacturing Engineers, maintaining the correct focal distance can improve cleaning efficiency by 40%.

Tip: Always conduct a test run on a small area to determine the right settings and adjust based on material response.

Regular maintenance checks, including lens cleaning and system diagnostics, are crucial. A well-maintained laser cleaner not only extends its lifespan but also keeps efficiency high. Remember, safety first—wear protective equipment at all times and ensure adequate ventilation in your workspace.

Tip: Utilize digital monitoring tools to track the performance and usage of your laser cleaner—this can identify potential issues before they become significant problems.

Maintenance Tips for Ensuring Longevity of Your Laser Cleaning Equipment

To ensure the longevity of your portable 1000w laser cleaner, regular maintenance is essential. First, ensure that the optical components are kept clean and free from dust or debris. Use a soft, lint-free cloth to gently wipe the lens and mirrors, as even minor contaminants can affect performance and output quality. Additionally, routinely check for any signs of wear or damage to the components, as early detection can prevent costly repairs or replacements down the line.

Another important aspect of maintenance involves proper storage and handling. When not in use, store the laser cleaner in a dry, dust-free environment to prevent corrosion and contamination. Regularly inspect the equipment's cables and connections to ensure they remain intact and functional. Employing a checklist for routine inspections can help streamline this process and provide peace of mind that your laser cleaner is operating at its best, which is crucial for maintaining efficiency in industrial applications. By following these maintenance tips, you can maximize the lifespan of your laser cleaning equipment and enhance its performance.

Common Applications of 1000w Laser Cleaners in Various Industries

The 1000w laser cleaner is rapidly gaining traction across various industries due to its efficiency and minimal environmental impact. One notable application is in the manufacturing sector, particularly for removing rust, paint, and contaminants from metal surfaces. Reports indicate that traditional cleaning methods can consume significant energy and generate harmful waste, whereas laser cleaning significantly reduces both energy consumption and environmental footprint. For instance, a study revealed that laser cleaning processes can cut down energy usage by up to 90%, showcasing a stark contrast to conventional methods.

In the automotive industry, the 1000w laser cleaner is increasingly utilized for surface preparation and restoration of components, ensuring optimal adhesion for coatings and paints. This technology not only enhances the quality of finished products but also reduces the need for harmful chemical solvents. Additionally, as industries pivot toward sustainability, the implementation of laser cleaning aligns with evolving regulations aimed at minimizing ecological impact. With the advancement of materials like gallium nitride and silicon carbide, cleaner and more efficient power devices are emerging, further emphasizing the significance of energy-efficient solutions in modern industrial practices.

FAQS

: Laser cleaning technology enhances surface preparation and maintenance by removing contaminants without harsh chemicals or abrasives, leading to improved productivity and a reduced ecological impact.

The global laser cleaning market is expected to reach USD 1.07 billion by 2025, driven by the demand for environmentally friendly cleaning solutions across various sectors.

Studies indicate that laser cleaning can improve productivity by up to 30% compared to traditional methods, and it can reduce cleaning time by up to 90%.

Operators should wear personal protective equipment, establish clear operational zones, and conduct thorough risk assessments to ensure safety while using laser cleaning equipment.

Regular maintenance checks, including lens cleaning and system diagnostics, ensure the laser cleaner remains efficient and prolongs its lifespan.

Set up in a clean, well-lit workspace on a stable surface, ensure all safety features are in place, connect the power supply securely, and adjust settings based on material response.

Yes, by minimizing ecological impact and improving operational efficiency, laser cleaning supports organizations in achieving their sustainability objectives.

Conducting a test run helps determine the appropriate settings for different materials, ensuring optimal cleaning results.

Proper training in laser safety protocols is essential for operators to handle the equipment safely and effectively, reducing the risk of accidents.

Digital monitoring tools help track the performance and usage of laser cleaners, allowing for the identification of potential issues before they develop into significant problems.

Conclusion

The blog titled "How to Effectively Use Portable 1000w Laser Cleaner for Industrial Applications" provides comprehensive insights into harnessing the power of this advanced cleaning technology. It begins by explaining the fundamentals of portable 1000w laser cleaners and highlights their numerous benefits in industrial settings, such as efficiency and eco-friendliness. Safety precautions when operating this equipment are crucial, ensuring user protection while maximizing performance.

Additionally, the blog offers a detailed step-by-step guide for setting up the laser cleaner and includes essential maintenance tips to prolong its lifespan. Finally, it explores various applications across industries, showcasing how Maven Laser Automation Co., Ltd., a leading manufacturer in the field, contributes to modernizing cleaning processes with its innovative laser solutions. This resource serves as a valuable tool for industries looking to optimize their cleaning practices using portable 1000w laser cleaners.

Related Posts

-

Key Factors to Identify Reliable Manufacturers for the Best 3000w Handheld Laser Cleaner

-

7 Tips for Choosing the Best Pulse Laser Cleaning Machine for Rust Removal

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

China's Commitment to Excellence in Manufacturing the Best Fiber Laser Marking Machine 100w

-

Future Market Trends for Best Fiber Laser Engraving Machines Towards 2025 with Real World Applications

-

How to Choose the Best 100w Fiber Laser Engraving Machine for Your Business

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top