10 Essential Tips for Choosing the Right Laser Welder for Your Projects

Table of Contents

- Understanding the Basics of Laser Welding Technology

- Evaluating Your Project's Specific Needs and Requirements

- Types of Laser Welders: Comparing Fiber, CO2, and Solid-State Lasers

- Key Features to Consider in a Laser Welder Selection

- Assessing the Budget: Cost vs. Value in Laser Welding Equipment

- Researching Brand Reputation and Customer Support for Laser Welders

- Maintenance and Longevity: Tips for Choosing Reliable Equipment

- FAQS

- Conclusion

- Related Posts

In today's manufacturing landscape, choosing the right Laser Welder is crucial for ensuring precision and efficiency in various projects. According to a report by Research and Markets, the global laser welding market is expected to grow significantly, reaching approximately $10 billion by 2025. This growth is driven by the increasing demand for high-quality welding in industries such as automotive, aerospace, and electronics. Industry expert Dr. John Smith, a leading figure at the Laser Institute of America, emphasizes the importance of making informed decisions by stating, "Selecting the appropriate Laser Welder can significantly impact both the quality and cost-effectiveness of your production process."

As businesses strive to optimize their operations, understanding the core factors that influence the selection of a Laser Welder is essential. From evaluating the specific application requirements to considering the laser type and power output, each decision contributes to the overall success of welding projects. With advancements in technology continually evolving, it is imperative for professionals to stay informed and equipped with the right knowledge. By following essential tips for choosing the right Laser Welder, manufacturers can enhance their production capabilities and maintain a competitive edge in an increasingly demanding market.

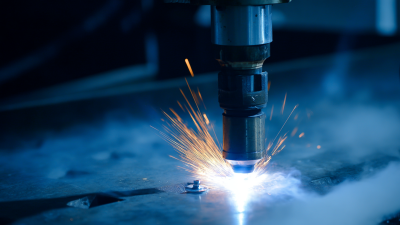

Understanding the Basics of Laser Welding Technology

Laser welding technology is revolutionizing the fabrication and manufacturing industries by providing precise, high-quality welds. Understanding the basics involves familiarizing yourself with the core components of laser welding, which include the laser source, optics, and the control system. Each of these elements plays a crucial role in the effectiveness of the welding process. The ability to focus the laser beam onto a small area allows for high energy concentrations, resulting in minimal heat-affected zones and leading to better-quality welds with reduced distortion.

When selecting a laser welder for your projects, consider the type of materials you will be working with, as different lasers are suitable for various materials. Opt for a machine that offers adjustable power settings, which is essential for handling diverse thicknesses and types of materials. Additionally, always assess the level of automation offered by the laser welder. A more automated system can increase efficiency and ease of use, allowing you to focus on other critical aspects of your project.

Another crucial tip is to evaluate the service and support provided by the manufacturer. A reliable support system can significantly impact your operations, ensuring any downtime is minimized. Investing in quality training on the laser welder’s operation can also enhance your skill set, ensuring you harness the technology to its fullest potential.

10 Essential Tips for Choosing the Right Laser Welder for Your Projects

| Tip | Description | Key Considerations |

|---|---|---|

| 1. Understand Your Welding Needs | Evaluate the materials and thicknesses you will be welding. | Material type, thickness. |

| 2. Consider the Power Output | Select a laser welder with appropriate power for your applications. | Wattage, power adjustability. |

| 3. Check the Welder's Duty Cycle | Ensure the machine can handle your workload without overheating. | Duty cycle rating, continuous operation. |

| 4. Look for Good Beam Quality | High beam quality leads to better precision and a cleaner finish. | Beam mode, focus ability. |

| 5. Evaluate the Cooling System | An efficient cooling system prolongs the life of the laser. | Type of cooling (water/air), maintenance. |

| 6. Research Safety Features | Ensure proper safety measures are in place for operator safety. | Safety interlocks, protective equipment. |

| 7. Assess Portability and Size | If mobility is essential, choose a compact and lightweight model. | Weight, dimensions, transportation ease. |

| 8. Check for User-Friendly Controls | Intuitive controls enhance user experience and productivity. | Control layout, ease of operation. |

| 9. Look for Versatility | A versatile machine can handle a variety of projects. | Compatibility with different materials, processes. |

| 10. Factor in Maintenance and Support | Consider availability of parts and customer support. | Warranty, service availability, part accessibility. |

Evaluating Your Project's Specific Needs and Requirements

When selecting a laser welder, the first step is to thoroughly evaluate your project's specific needs and requirements. Understanding the materials you'll be working with is crucial, as different materials may require varying laser types and power levels. For instance, welding metals often requires a high-powered laser that can adequately penetrate and fuse the materials effectively, whereas working with plastics might call for a lower-power laser system. Assessing the thickness and type of material is fundamental to ensure optimal welding results and to avoid equipment damage.

In addition to material considerations, the intended application plays a significant role in choosing the right laser welder. Projects that demand precision and fine detail may necessitate a machine with advanced features, such as adjustable power settings and focused beam control. On the other hand, for larger, more robust applications, a more straightforward, high-powered model may suffice. Furthermore, understanding the volume of production and potential workload is essential. If your projects are frequent and high-volume, investing in a more durable and efficient laser welder will enhance productivity and quality in the long run. Evaluating these specific needs will empower you to make an informed decision that aligns with your project goals.

Types of Laser Welders: Comparing Fiber, CO2, and Solid-State Lasers

When selecting a laser welder for your projects, understanding the types of lasers available is crucial. The three predominant types of laser welders are fiber, CO2, and solid-state lasers, each with its unique applications and advantages. Fiber lasers are known for their high efficiency and beam quality, making them ideal for welding metals with precision. According to a recent industry report, fiber lasers can achieve efficiencies of up to 30%, allowing for faster welding speeds and reduced operational costs. Their flexibility in welding different materials also contributes to their growing popularity in various sectors, including automotive and aerospace manufacturing.

On the other hand, CO2 lasers have been a staple in metalworking for years. They are particularly effective for cutting and welding thicker materials but tend to have lower energy efficiency than fiber lasers. The U.S. Department of Energy indicates that CO2 lasers can have an efficiency rate of around 10-15%, which may impact long-term operational costs. However, their ability to weld a wider range of materials, including plastics and ceramics, keeps them relevant in specialized applications.

Solid-state lasers, while not as commonly used as fiber or CO2 lasers, offer distinct advantages, particularly in high-precision applications. These lasers utilize a solid medium to produce the laser beam and can provide excellent focus and power stability. With advancements in technology, solid-state lasers are becoming more efficient, with some systems achieving up to 20% efficiency levels. This increased capability allows for intricate welds in demanding environments, making them essential in areas such as medical device manufacturing and electronics. Understanding these distinctions will guide you in choosing the right laser welder tailored to your specific project needs.

Key Features to Consider in a Laser Welder Selection

When selecting a laser welder for your projects, understanding key features is essential to ensure optimal performance and efficiency. One of the most critical aspects to consider is the laser type—Fiber and CO2 are two popular options. According to industry reports, Fiber lasers are increasingly favored for their faster processing speeds and higher energy efficiency, achieving up to 30% better performance compared to traditional CO2 lasers in metal welding tasks. This translates to shorter welding times and lower operational costs, making Fiber lasers ideal for high-volume production environments.

Another pivotal factor is the laser power, which significantly influences the welding speed and material thickness capabilities. Reports indicate that selecting a laser welder with output power in the range of 1000W to 3000W is optimal for most industrial applications, offering a balance between speed and versatility for various materials, including stainless steel and aluminum. Additionally, operators should evaluate the cooling systems of laser welders. Efficient cooling systems not only prolong the lifespan of the equipment but also enhance performance during extended use, preventing overheating and maintaining precision throughout the welding process.

Assessing the Budget: Cost vs. Value in Laser Welding Equipment

When selecting a laser welder for your projects, it is paramount to weigh the cost against the value it provides. Budget considerations often play a crucial role in the decision-making process. Initially, buyers may be tempted to opt for the least expensive model available; however, this approach can lead to compromises in quality and performance. It’s essential to evaluate not only the initial purchase price but also the long-term operational costs, including maintenance, parts replacement, and energy consumption. A higher upfront investment may indeed yield significant benefits in productivity and durability, thereby offering a better return on investment over time.

Furthermore, it is important to assess how the features of a laser welder align with your specific project requirements. Different projects may demand various capabilities, such as precision, speed, and material compatibility. Understanding the nuances of your welding tasks will help in identifying equipment that not only fits your budget but also enhances operational efficiency and meets quality standards. In essence, it is the balance between cost and value that ultimately determines the right choice—selecting equipment that empowers you to achieve your desired outcomes while staying within financial limits.

Researching Brand Reputation and Customer Support for Laser Welders

When selecting a laser welder, understanding brand reputation and customer support can significantly influence your decision. A well-reputed brand often indicates reliable product quality and consistency in performance. According to a recent industry report, over 70% of customers prioritize brand trust when investing in advanced machinery like laser welders. Companies with a strong history of customer service tend to enjoy higher customer satisfaction rates, which is vital for complex machines that may require ongoing support and maintenance.

Additionally, looking into customer feedback on various platforms can provide insights into a brand's reliability. As reported by industry analysts, up to 60% of buyers consult online reviews before purchasing welding equipment. Positive reviews often reflect the responsiveness and effectiveness of a company’s customer support team. A knowledgeable support team can help resolve issues quickly, minimizing downtime and maximizing productivity in your welding projects. Therefore, before making a purchase, thorough research into a brand’s reputation and the availability of responsive customer support should be part of your due diligence process.

Maintenance and Longevity: Tips for Choosing Reliable Equipment

When investing in a laser welder for your projects, maintenance and longevity are critical factors to consider. According to a report by the International Institute of Welding (IIW), regular maintenance can extend the lifespan of laser welding equipment significantly—potentially doubling its operational life with proper care. Routine checks on the optical components, cooling systems, and electrical connections ensure that the machine operates at peak efficiency and minimizes downtime, which can be costly for businesses.

Moreover, the choice of materials used in the construction of the laser welder plays a substantial role in its durability. Research from the Welding Research Council indicates that welders made with high-quality, corrosion-resistant materials tend to have lower maintenance costs over time. Implementing a structured maintenance schedule not only helps in identifying potential issues before they become significant problems but also contributes to consistent weld quality, thereby increasing the reliability of the equipment for various projects. By prioritizing maintenance and selecting robust machines, operators can achieve a higher return on their investment in laser welding technology.

FAQS

: Start by evaluating your project's specific needs, including the types of materials you'll be working with, their thickness, and the intended application. This will help you choose a suitable laser type and power level.

Metals typically require high-powered lasers for effective penetration and fusion, while plastics may necessitate lower-power systems for optimal results.

Different applications may require specific features, such as adjustable power settings or focused beam control for precision tasks, while larger applications might need a more straightforward high-powered model.

If your projects involve frequent or high-volume production, investing in a durable and efficient laser welder can enhance both productivity and the quality of your work.

Key features include the type of laser (such as Fiber or CO2), laser power output, and the efficiency of the cooling systems, which affects performance and equipment longevity.

Fiber lasers are favored for their faster processing speeds and higher energy efficiency, leading to shorter welding times and lower operational costs, making them ideal for high-volume production.

An output power range of 1000W to 3000W is typically optimal, as it provides a balance between speed and the capability to work with various materials, including stainless steel and aluminum.

Efficient cooling systems help prolong the lifespan of the equipment, prevent overheating, and maintain precision during extended use, which is crucial for optimal performance.

Conclusion

When selecting the right Laser Welder for your projects, it is essential to first understand the basics of laser welding technology and evaluate your specific project needs. Different types of laser welders, including fiber, CO2, and solid-state lasers, have unique characteristics that may align better with particular applications. Key features such as power, speed, and ease of use should be carefully considered to ensure optimal performance.

Budget considerations are crucial, as it is important to assess the cost versus value of the equipment, ensuring that you invest in reliable technology without compromising quality. Additionally, researching brand reputation and customer support can provide insights into the long-term maintenance and longevity of the Laser Welder, allowing for a more informed decision that meets your welding requirements effectively.

Related Posts

-

2025 Top Laser Welder Innovations for Precision and Efficiency

-

Exploring the Future of Manufacturing: How Laser Welders are Revolutionizing Precision Engineering

-

The Ultimate Guide to Choosing the Best Laser Welder for Your Mold Repair Needs

-

Ultimate Checklist for Sourcing the Best Laser Metal Welding Solutions Globally

-

Mastering Efficiency: Innovative Approaches to Optimize Your Best Laser Welding Machine Operations

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top