7 Expert Tips for Choosing the Best Laser For Rust Removal

Table of Contents

- Understanding Different Types of Lasers for Rust Removal

- Evaluating Laser Power and Its Impact on Rust Removal Efficiency

- Considering Portability and Ease of Use in Laser Selection

- Assessing Safety Features and Protective Gear for Laser Operations

- Budgeting for Your Laser Purchase: Cost vs. Quality Considerations

- Researching Customer Reviews and Expert Opinions on Laser Models

- FAQS

- Conclusion

- Related Posts

In today’s industrial landscape, rust removal has become a crucial aspect of maintenance and upkeep for a variety of applications, from automotive to manufacturing. According to recent industry reports, the market for laser technology, particularly for rust removal, is projected to grow significantly, with laser systems increasingly recognized for their efficiency and precision. As a leading manufacturer of laser systems, Maven Laser Automation Co., Ltd. is well-positioned to address these needs, offering innovative solutions since its establishment in 2008. The adoption of Laser For Rust Removal not only enhances the quality of surface treatment but also improves operational effectiveness, making it an attractive alternative to traditional methods. As industries seek to optimize their processes, understanding the nuances of choosing the right laser technology becomes paramount in achieving desired outcomes and maximizing return on investment.

Understanding Different Types of Lasers for Rust Removal

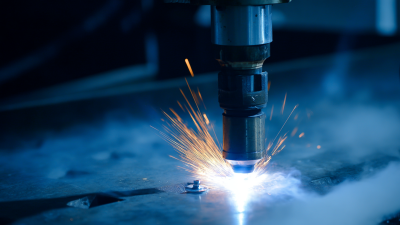

When it comes to rust removal, selecting the right type of laser is crucial for achieving optimal results. There are various lasers available, each designed for different applications and materials. Fiber lasers, for instance, are highly effective for removing rust from metal surfaces due to their precision and efficiency. They generate a concentrated beam of light that can quickly vaporize rust, making them an ideal choice for heavy-duty tasks.

Another option is CO2 lasers, which are more suited for softer materials but can still aid in rust removal when used with the right settings. These lasers excel in cutting and engraving, and while they may not be as powerful as fiber lasers for rust removal, they can be effective in less severe rust scenarios. It’s essential to consider the specific needs of your project and the material you are working with to choose the best laser.

When selecting your laser, it's vital to consult with experts who can guide you based on your particular requirements. Moreover, always evaluate the maintenance and operational costs associated with the laser type to ensure it aligns with your budget. Understanding these factors will help you make an informed decision, ensuring a successful rust removal process.

Evaluating Laser Power and Its Impact on Rust Removal Efficiency

When it comes to choosing a laser for rust removal, evaluating the laser power is crucial for ensuring efficiency and effectiveness. Studies from the Laser Institute of America indicate that lasers with power levels between 100 to 400 watts are generally optimal for rust removal, striking a balance between speed and substrate safety. Higher-powered lasers can remove rust more quickly but may require more careful handling to avoid unwanted damage to the underlying material.

Additionally, the wavelength of the laser plays a significant role in penetrating rust layers. Research highlighted in the Journal of Materials Processing Technology indicates that lasers with a wavelength of around 1064 nm, such as fiber and Nd:YAG lasers, are particularly effective because they can penetrate deeper and interact more efficiently with rust particles. This ability not only enhances the removal process but also reduces the risk of re-oxidation on the treated surfaces, ultimately leading to longer-lasting results. Thus, understanding these technical specifications is vital for selecting the right laser for rust removal tasks.

Laser Power Impact on Rust Removal Efficiency

Considering Portability and Ease of Use in Laser Selection

When selecting a laser system for rust removal, portability and ease of use are critical considerations. A recent industry report indicates that over 60% of professionals prioritize these factors when investing in laser cleaning technologies. This demand is primarily driven by the need for efficient and versatile solutions in various environments, including onsite service applications and hard-to-reach areas.

Maven Laser Automation Co., Ltd., a leader in the laser industry since its establishment in 2008, offers a range of portable laser systems that cater to these needs. Designed with user-friendliness in mind, Maven’s lasers demonstrate that efficient rust removal does not have to come at the expense of convenience. The integration of advanced automation solutions further simplifies operation, enabling technicians to focus on results rather than complicated machine settings. With robust performance metrics, these systems ensure that users can achieve optimal cleaning results while minimizing downtime, making them an excellent investment for businesses seeking to enhance productivity in rust removal operations.

Assessing Safety Features and Protective Gear for Laser Operations

When considering the use of lasers for rust removal, assessing safety features and protective gear is paramount. According to the National Institute for Occupational Safety and Health (NIOSH), laser operations pose inherent risks such as eye damage and skin burns, making proper safety measures critical. Operators should invest in high-quality laser goggles that meet ANSI Z87.1 standards to ensure adequate eye protection against the specific wavelength of the laser being utilized. Furthermore, a lab report by the Laser Institute of America emphasizes that using proper shielding and barriers can significantly reduce the risk of unintended exposure during operations.

In addition to personal protective equipment, it's essential to integrate comprehensive safety protocols into laser operations. A survey from the Occupational Safety and Health Administration (OSHA) found that workplaces implementing structured safety training programs have seen a 30% reduction in accidents related to laser equipment. This emphasizes the importance of using protective gear such as gloves, aprons, and even respirators in certain environments. By prioritizing safety features and equipping operators with the right protective gear, companies can not only comply with regulatory requirements but also foster a safer working environment.

Budgeting for Your Laser Purchase: Cost vs. Quality Considerations

When considering a laser for rust removal, budgeting is essential, balancing cost with quality to ensure effective results. Industry reports indicate that high-quality laser systems can range from $5,000 to over $100,000 depending on the technology and expertise required. For instance, the American Laser Institute highlights that investing in a more robust system can save costs in the long run by minimizing maintenance and downtime, showcasing a potential decrease in operational costs by 30% over five years.

Moreover, it's crucial to assess the output power and efficiency of the laser. According to a study by the International Society of Laser Applications, lasers with a minimum output of 100 watts are recommended for effective rust removal. Though initial expenses for such equipment might be higher, the improved performance can lead to significant productivity gains. For example, machines that are designed specifically for industrial applications can operate at speeds up to 20 square meters per hour, cutting labor costs significantly. Thus, while it may be tempting to choose a lower-priced option, understanding the long-term value based on performance is key to making an informed decision.

7 Expert Tips for Choosing the Best Laser For Rust Removal - Budgeting for Your Laser Purchase: Cost vs. Quality Considerations

| Feature | Description | Cost Range | Quality Rating (1-5) |

|---|---|---|---|

| Power | Higher power lasers remove rust quicker but can be more expensive. | $500 - $5,000 | 4 |

| Wavelength | The wavelength affects absorption and performance on various material types. | $400 - $3,500 | 5 |

| Portability | Consider whether you need a stationary or mobile laser for your work. | $300 - $4,000 | 3 |

| Ease of Use | A user-friendly interface can save time and reduce errors. | $200 - $2,500 | 4 |

| Maintenance | Some lasers require more upkeep than others. | $100 - $1,000/year | 3 |

| Durability | Built to last even with frequent heavy use. | $600 - $5,500 | 5 |

| Support & Training | Consider the availability of customer support and training. | $0 - $500 | 4 |

Researching Customer Reviews and Expert Opinions on Laser Models

When it comes to selecting the best laser for rust removal, researching customer reviews and expert opinions on various laser models can significantly influence your decision. Customers often share firsthand experiences that provide insight into the effectiveness, ease of use, and durability of different products. These reviews can highlight how well a certain laser removes rust, its compatibility with various surfaces, and any maintenance issues that might arise. By paying close attention to the feedback from actual users, you can more accurately gauge how a model performs in real-world conditions.

Additionally, expert opinions can guide you in navigating the technical specifications and features of laser systems. Professionals in the field can provide valuable insights into which laser types are best suited for specific applications, helping you understand the advantages of different wavelengths, power outputs, and automation capabilities. As a leading manufacturer of laser systems, Maven Laser Automation Co., Ltd. emphasizes the importance of combining customer feedback with expert advice to develop products that meet industry needs. By considering both perspectives, you can make a more informed choice that aligns with your rust removal objectives.

FAQS

: Portability is important because over 60% of professionals prioritize it when investing in laser cleaning technologies, as it allows for efficient work in various environments, including onsite services and hard-to-reach areas.

Maven Laser Automation Co., Ltd. offers a range of portable laser systems designed with user-friendliness in mind, integrating advanced automation solutions that simplify operation for technicians.

A key consideration is balancing cost with quality to ensure effective results, especially since high-quality laser systems can range from $5,000 to over $100,000 depending on technology and expertise.

Investing in a more robust system can minimize maintenance and downtime, potentially decreasing operational costs by 30% over five years.

Lasers with a minimum output of 100 watts are recommended for effective rust removal, as indicated by a study from the International Society of Laser Applications.

High-quality laser systems designed for industrial applications can operate at speeds up to 20 square meters per hour, significantly cutting labor costs.

Advanced automation solutions simplify machine operations, allowing technicians to focus on results rather than complex settings, leading to optimal cleaning results and minimized downtime.

Buyers should avoid opting for lower-priced options without considering long-term value and performance, as a more expensive, higher-quality system may offer better efficiency and cost savings in the long run.

Conclusion

When selecting the best laser for rust removal, it's essential to understand the various types of lasers available and how their power affects rust removal efficiency. Portability and ease of use should also be key considerations, especially for users who need flexibility in their operations. Additionally, safety features and appropriate protective gear are critical for ensuring safe usage in any environment.

Budgeting wisely is crucial, as one must balance cost considerations with quality to ensure a worthwhile investment. Lastly, researching customer reviews and expert opinions on different laser models can provide valuable insights to help make an informed decision. At Maven Laser Automation Co., Ltd., we take pride in offering advanced laser systems, ensuring that our customers can find the perfect laser for rust removal that meets their specific needs and standards.

Related Posts

-

Comprehensive Solutions for Efficient Rust Removal with the Best 3000W 4-In-1 Laser Cleaning Machine

-

How to Select the Best Fiber Laser Cutting Machine Manufacturers: Key Industry Insights

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

-

7 Best Reasons to Invest in a Rust Cleaning Laser Machine

-

5 Essential Tips for Using Pulse Laser Cleaning Machine for Rust Removal

-

Maximizing Value with Best Portable Laser Cleaner With Battery Through Cost Effective Maintenance and Support

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top