The Future of Affordable Laser Machine Price Innovations

Table of Contents

- The Evolution of Laser Technology and Its Impact on Affordability

- Key Factors Driving Down Laser Machine Prices

- Innovations in Material and Production Processes for Cost Reduction

- The Role of Competition in Shaping Affordable Laser Machine Markets

- Future Trends: Predicting the Demand for Budget-Friendly Laser Solutions

- FAQS

- Conclusion

- Related Posts

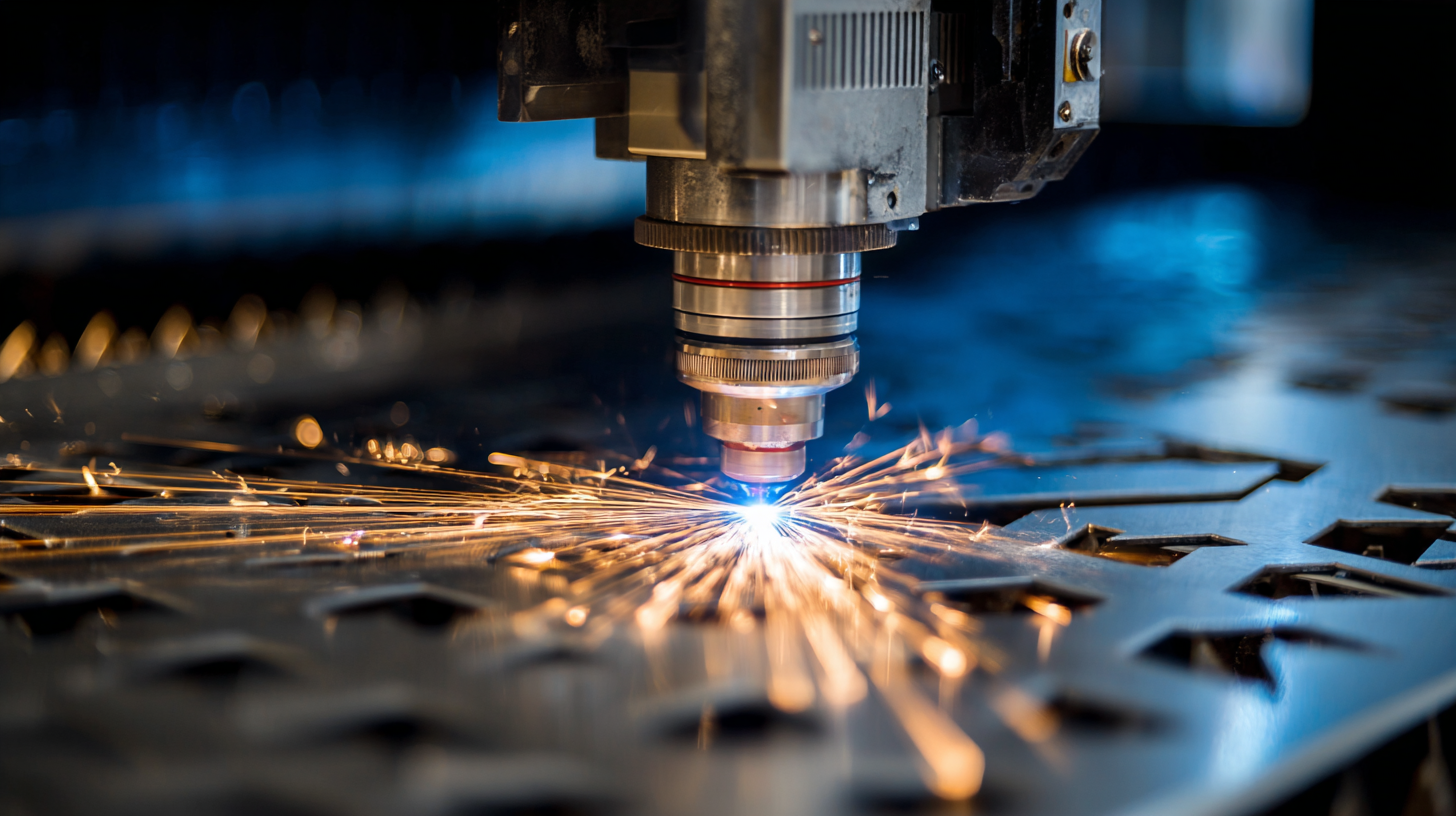

In the rapidly evolving landscape of manufacturing and automation, the quest for affordability and efficiency has led to significant innovations in laser technology. At the forefront of this revolution is Maven Laser Automation Co., Ltd., a distinguished manufacturer based in Shenzhen, China, established in 2008. Specializing in laser systems and professional automation solutions, Maven Laser has made a notable impact on the industry, beginning its journey with the design, production, and sales of laser cases.

As we look to the future, the discussion surrounding Laser Machine Price becomes increasingly relevant, prompting us to explore how technological advancements and strategic innovations can make high-quality laser machines more accessible to a broader range of industries. This blog will delve into the anticipated developments and innovative solutions aimed at reducing costs while maintaining performance, making laser technology an attainable resource for businesses of all sizes.

The Evolution of Laser Technology and Its Impact on Affordability

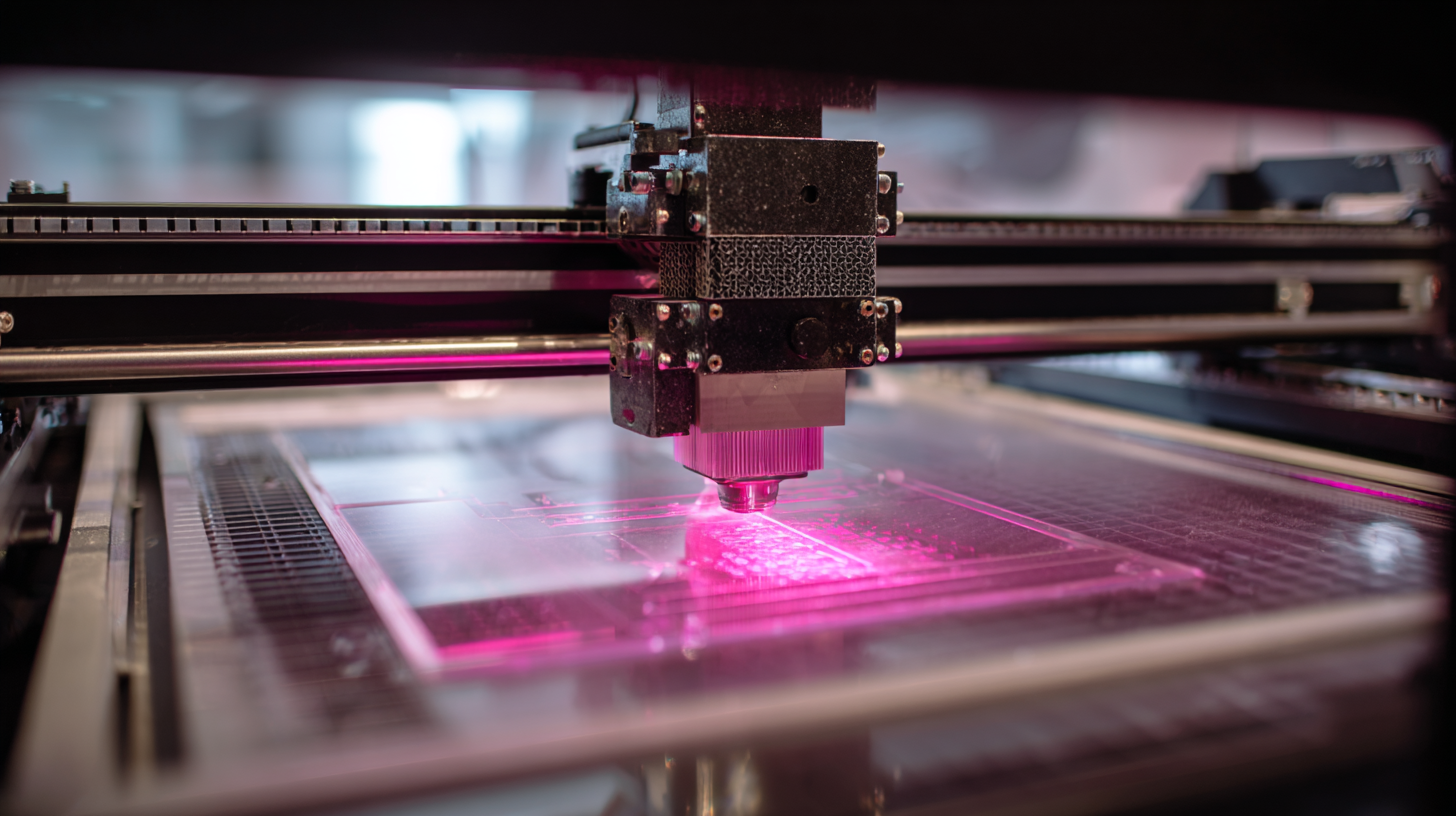

The rapid evolution of laser technology has transformed its accessibility and affordability significantly. With innovations such as the integrated 3D mapping solutions that leverage both laser radar and visual algorithms, costs have dramatically decreased, making advanced laser systems more accessible for various industries. For instance, new systems priced in the range of a few thousand units are capable of covering areas exceeding one million square meters, showcasing how these advancements can deliver high precision at a fraction of the previous cost.

As businesses explore the most effective perception solutions, the debate between laser radar and visual algorithms continues. The high-resolution point cloud generated by laser systems provides unparalleled accuracy, while visual algorithms enhance operational flexibility. Companies in automation, like Maven Laser Automation, are at the forefront, delivering professional solutions that adapt to these evolving needs, ultimately enhancing productivity and efficiency across sectors.

Tip: When considering laser technology for your business, evaluate both cost-efficiency and the specific requirements of your applications. Investing in a versatile solution that combines both laser and visual elements can provide a competitive edge. Additionally, stay informed about emerging trends to ensure your business leverages the latest advancements in laser automation technologies.

Key Factors Driving Down Laser Machine Prices

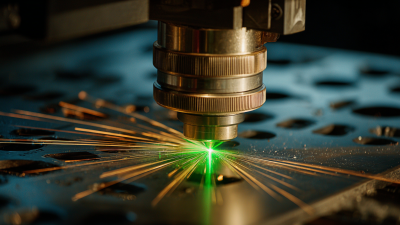

The landscape of laser machining is rapidly evolving, driven by several key factors that are significantly reducing prices. Technological advancements in laser technology have led to the development of more efficient machines that require less maintenance and energy, making them more cost-effective for manufacturers. Innovations in materials and components also contribute to lowered production costs, allowing suppliers to pass these savings onto consumers. As competition in the market intensifies, manufacturers are prompted to innovate further, driving a cycle of improved affordability and accessibility.

Tip: When considering investment in a laser machine, evaluate the long-term costs versus initial price. Sometimes a higher initial investment may lead to greater savings over time due to lower operational costs.

Additionally, increased demand for precision cutting and engraving across various industries, including automotive and aerospace, is pushing manufacturers to scale operations. This surge in demand encourages mass production, which can drive economies of scale that reduce overall prices. Coupling this with a growing number of new entrants into the market introduces diverse pricing strategies that further promote affordability.

Tip: Stay informed on industry trends and emerging technologies, as these can affect machine pricing and availability, ensuring you make well-timed purchasing decisions.

The Future of Affordable Laser Machine Price Innovations - Key Factors Driving Down Laser Machine Prices

| Dimension | 2021 Price (USD) | 2022 Price (USD) | 2023 Price (USD) | Price Change (%) |

|---|---|---|---|---|

| Entry-Level Laser Cutter | $3,500 | $3,200 | $2,800 | -20% |

| Mid-Range Laser Engraver | $10,000 | $9,500 | $8,000 | -20% |

| Industrial Laser Cutter | $50,000 | $47,500 | $40,000 | -20% |

Innovations in Material and Production Processes for Cost Reduction

The rapid evolution of laser machine technology has led to significant innovations in material selection and production processes, ultimately driving down costs. Recent industry reports indicate that laser cutting equipment prices could decrease by up to 20% over the next five years, primarily due to advancements in fiber laser technology and manufacturing efficiencies. These innovations not only enhance the performance of laser machines but also allow for the use of less expensive materials without sacrificing quality.

To capitalize on these advancements, businesses should consider upgrading their equipment to take advantage of the latest technologies, such as automation in production processes, which can reduce labor costs by approximately 30%. Investing in training for staff on these new systems can further enhance efficiency.

**Tip:** When evaluating new laser systems, prioritize those with integrated software that allows for easy material adjustments and efficiency tracking.

Moreover, the development of alternative materials—such as composites and lower-cost metals—has opened new avenues for production, reducing waste and improving overall operational costs. Adopting these materials can significantly lower the cost per unit while maintaining the integrity of the final product.

**Tip:** Regularly assess supplier offers for new material options to find cost-effective alternatives that meet your production needs.

The Role of Competition in Shaping Affordable Laser Machine Markets

The competitive landscape within the laser machine market plays a pivotal role in driving affordability and innovation. Recent market analyses, such as the report from MarketsandMarkets, have projected that the global laser cutting machine market is expected to reach approximately $5 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth trajectory indicates that as more players enter the market, the competition intensifies, prompting manufacturers to optimize their production processes and reduce costs, ultimately benefiting consumers with more affordable options.

Moreover, the advent of technologies such as fiber lasers and advancements in manufacturing techniques has created a ripple effect across the industry. According to a study by Grand View Research, the fiber laser segment is anticipated to dominate the market share with rapid technological advancements enabling lower operational costs. As established companies and innovative startups compete for market share, they not only push for price reductions but also enhance the overall quality and functionality of laser machines. This dynamic interaction ensures that the end-users can access high-quality, cost-effective solutions, thereby expanding the applications of laser machinery in various sectors, from manufacturing to healthcare.

Future Trends: Predicting the Demand for Budget-Friendly Laser Solutions

As the laser technology sector continues to evolve, the demand for budget-friendly laser solutions is gaining momentum. According to a recent report by ResearchAndMarkets, the global laser market is projected to reach $18.7 billion by 2026, with a significant portion of this growth driven by small and medium-sized enterprises (SMEs) seeking affordable options. This trend indicates that businesses looking to enhance their operational efficiency without heavy financial investment are increasingly turning to laser systems that offer high-performance capabilities at lower price points.

Moreover, the rise of technological innovations, such as fiber laser technology, is playing a crucial role in making laser machines more accessible. A report from MarketsandMarkets states that the fiber laser segment is expected to grow from $3.6 billion in 2021 to $8.1 billion by 2026, highlighting the shrinking gap between cost and performance. As manufacturers streamline production processes and harness advancements in materials and engineering, the affordability of laser machines will not only satisfy existing demand but also encourage new sectors to embrace these cutting-edge solutions.

The Future of Affordable Laser Machine Innovations

FAQS

: Recent advancements in fiber laser technology and manufacturing efficiencies are projected to decrease laser cutting equipment prices by up to 20% over the next five years.

Upgrading to the latest technologies, including automation, can reduce labor costs by approximately 30% and improve overall production efficiency.

The adoption of alternative materials, such as composites and lower-cost metals, can significantly lower the cost per unit while maintaining product integrity.

Investing in staff training on new systems can enhance efficiency and ensure that the equipment is utilized to its fullest potential.

Businesses should prioritize laser systems with integrated software that facilitates easy material adjustments and efficiency tracking.

Increased competition in the laser machine market encourages manufacturers to optimize production processes and reduce costs, benefiting consumers with more affordable options.

The global laser cutting machine market is expected to reach approximately $5 billion by 2025, growing at a CAGR of 6.5%.

The fiber laser segment is anticipated to dominate market share due to rapid technological advancements enabling lower operational costs.

As established companies and startups compete for market share, they focus on price reductions while also enhancing the quality and functionality of laser machines.

Regularly assessing supplier offers can help businesses find cost-effective alternatives that meet their production needs, further optimizing operational costs.

Conclusion

The blog "The Future of Affordable Laser Machine Price Innovations" explores the transformative journey of laser technology and its implications for cost-effectiveness. It discusses the evolution of laser systems and highlights key factors driving down laser machine prices, such as advancements in materials and production processes. Furthermore, the piece examines how competition among manufacturers, like Maven Laser Automation Co., Ltd., fosters a market that prioritizes budget-friendly solutions.

In addition, the blog emphasizes future trends in the laser industry, predicting a rising demand for affordable laser solutions that cater to a broader audience. As a leading manufacturer in this field, Maven Laser Automation, established in 2008, plays a crucial role in shaping the landscape of laser technology, ensuring that innovations not only enhance performance but also make laser machines more accessible to businesses of all sizes.

Related Posts

-

Maximizing Value with Best Portable Laser Cleaner With Battery Through Cost Effective Maintenance and Support

-

China's Commitment to Excellence in Manufacturing the Best Fiber Laser Marking Machine 100w

-

5 Reasons Why the Portable Pulse Laser Cleaner is Essential for Modern Manufacturing

-

Excellence in Manufacturing with the Best Mini Fiber Laser Machine from China to the World

-

Revolutionary Applications of the 200W Laser Cleaner for Wood Restoration and Maintenance

-

Revolutionizing Manufacturing: The Future of Robotic Arm Welding and Its Impact on Industry Growth

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top