Unleashing the Future of Manufacturing with Advanced Robot Welding Machines

Table of Contents

- The Evolution of Robot Welding Technology in Modern Manufacturing

- Key Advantages of Implementing Advanced Robotic Welding Solutions

- Integrating AI and Machine Learning in Welding Robotics

- Best Practices for Optimizing Robot Welding Efficiency

- Future Trends: What’s Next for Robotic Welding in Manufacturing?

- FAQS

- Conclusion

- Related Posts

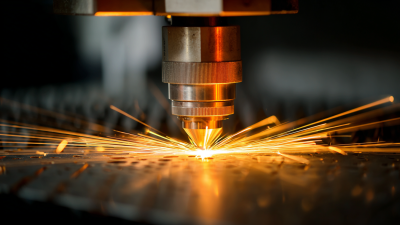

The manufacturing landscape is undergoing a significant transformation with the integration of advanced technologies, particularly Robot Welding Machines. According to a recent report by MarketsandMarkets, the global robotic welding market is projected to reach $4.51 billion by 2026, growing at a CAGR of 7.5% from 2021 to 2026. This growth is driven by the increasing need for automation in the manufacturing sector, promoting efficiency, precision, and reduced labor costs. Maven Laser Automation Co., Ltd., a leading manufacturer based in Shenzhen, China, has been at the forefront of this revolution since its inception in 2008. By leveraging cutting-edge laser systems and automation solutions, Maven Laser is positioned to enhance manufacturing processes and meet the growing demands of industries worldwide. Embracing Robot Welding Machines not only signifies a leap towards advanced manufacturing but also aligns with the industry's trend towards digital transformation and increased productivity.

The Evolution of Robot Welding Technology in Modern Manufacturing

The evolution of robot welding technology has played a pivotal role in transforming modern manufacturing. As industries face a growing demand for efficiency and quality, innovative approaches such as intelligent automation are becoming imperative. Integrating AI with robotic welding not only enhances process precision but also optimizes resource allocation, reducing waste and increasing sustainability. The advancements in robotic arms have allowed for intricate welding tasks to be completed with remarkable speed and accuracy, reinforcing the industry's commitment to maintaining high standards of production.

The evolution of robot welding technology has played a pivotal role in transforming modern manufacturing. As industries face a growing demand for efficiency and quality, innovative approaches such as intelligent automation are becoming imperative. Integrating AI with robotic welding not only enhances process precision but also optimizes resource allocation, reducing waste and increasing sustainability. The advancements in robotic arms have allowed for intricate welding tasks to be completed with remarkable speed and accuracy, reinforcing the industry's commitment to maintaining high standards of production.

Moreover, the demand for skilled labor remains a pressing issue, with a notable shortage of qualified welders across various sectors. This gap reinforces the need for automation solutions, such as collaborative robotics, which work alongside human operators to elevate productivity while ensuring safety. Companies like Maven Laser Automation Co., Ltd. are at the forefront of this evolution, providing advanced laser systems that streamline welding processes. As the industrial landscape continues to evolve, embracing these technological advancements will be critical in addressing labor challenges and driving further innovation in manufacturing.

Key Advantages of Implementing Advanced Robotic Welding Solutions

The global robotic welding market is on the rise, projected to grow from $8.1 billion in 2025 to $20.16 billion by 2032, demonstrating a robust CAGR of 13.9%. As industries seek innovative solutions to enhance efficiency and productivity, advanced robotic welding machines are becoming indispensable. These machines not only improve precision and reduce waste but also enable consistent quality in manufacturing processes.

Tips for Implementing Robotic Welding Solutions:

- Assess your production needs: Before investing in robotic welding technology, evaluate your operational requirements to ensure it aligns with your production goals.

- Train your workforce: Proper training for employees operating robotic welding machines is crucial to maximize their potential and minimize errors.

With the rise of AI and automation, the benefits of advanced robotic welding solutions extend beyond sheer efficiency. They also encompass enhanced safety, as robots can perform hazardous tasks without endangering human workers. This transformation in the manufacturing landscape ushers in not only improvements in output but also a commitment to sustainability through reduced resource consumption and minimal waste generation.

Unleashing the Future of Manufacturing with Advanced Robot Welding Machines - Key Advantages of Implementing Advanced Robotic Welding Solutions

| Key Advantage | Description | Impact on Manufacturing |

|---|---|---|

| Increased Precision | Robots perform welding with high accuracy, reducing error rates. | Enhances product quality and reduces waste. |

| Higher Speed | Robotic systems can operate continuously, increasing throughput. | Boosts production rates and meets market demands faster. |

| Labor Cost Reduction | Decreases reliance on manual labor for welding tasks. | Lowers operating costs over time. |

| Improved Safety | Reduces workers' exposure to hazardous environments. | Creates a safer workplace for employees. |

| Flexible Automation | Robots can be programmed for different welding tasks. | Supports diverse production runs and adaptability. |

Integrating AI and Machine Learning in Welding Robotics

The integration of artificial intelligence and machine learning into welding robotics is transforming the manufacturing sector. As the global AI robots market is projected to surge from $6.19 billion in 2025 to an astounding $32.26 billion, industries are reaping the benefits of enhanced productivity and efficiency. AI-enabled welding machines can adapt in real time to variations in materials and processes, improving weld quality while minimizing waste. This technological advancement not only streamlines operations but also addresses workforce shortages by allowing robots to take on complex tasks with precision.

Tips for manufacturers considering this shift include investing in training programs to help workers understand and collaborate with AI-driven systems. Additionally, it's crucial to choose the right technology partners who have a solid track record in robotics and AI, ensuring a smooth integration into existing systems. Emphasizing a culture of continuous improvement will also help organizations fully leverage the capabilities of next-generation welding robotics, driving innovation and maintaining a competitive edge in an increasingly automated landscape.

Best Practices for Optimizing Robot Welding Efficiency

Advanced robotic welding machines are at the forefront of enhancing manufacturing efficiency and productivity. As the reliance on automation in manufacturing grows, optimizing robot welding processes becomes essential. Studies have shown that integrating intelligent algorithms like the Physics-informed Hybrid Optimization framework can significantly elevate welding performance, minimizing rework while maximizing output. This data-driven approach leverages real-time monitoring and machine learning to adapt welding parameters dynamically, leading to substantial improvements in quality and speed.

Furthermore, the implementation of path optimization techniques, such as the advanced Ant Colony Approach, allows for more efficient routing in the welding process. By reducing travel time and optimizing the sequence of operations, manufacturers can significantly lower energy consumption and operational costs. A report by the International Federation of Robotics indicated that the adoption of collaborative robots can enhance workflows by up to 30%, illustrating the transformative impact of smart automation in welding applications. As industries advance into a future characterized by smart factories, the emphasis on optimizing robot welding will play a critical role in achieving higher efficiency standards and sustainability goals.

Future Trends: What’s Next for Robotic Welding in Manufacturing?

The future of robotic welding in manufacturing is set to undergo a significant transformation driven by advanced technologies and evolving industry needs. By 2030, the robotic welding market is projected to reach astonishing heights, with a substantial increase in both welding robots and cobots. A recent analysis indicates that the market size for robotic welding could exceed $10 billion, reflecting an increasing demand in sectors like automotive, aerospace, and construction. The integration of AI-driven systems is expected to enhance precision and efficiency, addressing challenges in complex welding environments while ensuring quality control.

Tips: When considering the adoption of robotic welding systems, manufacturers should assess their specific production needs and workflow to maximize productivity. Collaborating with technology providers can offer tailored solutions that better fit operational requirements.

Moreover, as the supply chain dynamics continue to evolve, manufacturers must remain agile. The rise of digital transformation paves the way for resilient logistics and automation strategies. By embracing these trends, companies can fill labor gaps and elevate throughput, ultimately driving innovation in the welding industry.

Tips: Regularly updating training programs and involving employees in the transition process can ease the adoption of robotic technologies, fostering a culture of continuous improvement.

FAQS

: The global robotic welding market is projected to grow from $8.1 billion in 2025 to $20.16 billion by 2032.

Key benefits include improved precision, reduced waste, consistent quality in manufacturing processes, and enhanced safety by performing hazardous tasks without endangering workers.

Proper training is crucial to maximize the potential of robotic welding machines and minimize errors during operation.

AI-enabled welding machines can adapt in real time to variations in materials and processes, improving weld quality while minimizing waste.

Manufacturers should invest in training programs for workers and choose technology partners with a strong track record in robotics and AI to ensure smooth integration.

These solutions reduce resource consumption and generate minimal waste, thereby supporting sustainability initiatives in manufacturing.

Robotics can address workforce shortages by taking on complex tasks with precision, allowing manufacturers to maintain productivity levels.

Organizations should emphasize a culture of continuous improvement to drive innovation and maintain a competitive edge.

Industries should assess their production needs to ensure that robotic welding technology aligns with their operational requirements.

The robotic welding market is growing alongside the expansion of the AI robots market, reflecting a broader trend toward automation that enhances efficiency and productivity across industries.

Conclusion

The article "Unleashing the Future of Manufacturing with Advanced Robot Welding Machines" explores the significant advancements in robot welding technology that are transforming modern manufacturing. It discusses the evolution of these machines, highlighting their key advantages such as increased precision, efficiency, and cost-effectiveness. The integration of AI and machine learning into welding robotics is a game-changer, enabling smarter decision-making and enhanced automation capabilities. Additionally, the article outlines best practices for optimizing robot welding efficiency to maximize productivity in manufacturing environments.

Looking ahead, the future trends in robotic welding suggest a continued evolution, with innovations likely to further streamline production processes. As a leader in laser systems and automation solutions, Maven Laser Automation Co., Ltd. recognizes the potential of robot welding machines to revolutionize the industry, aligning with its commitment to cutting-edge technology and excellence in manufacturing solutions.

Related Posts

-

Revolutionizing Manufacturing: How Robot Welding Machines Enhance Efficiency and Precision

-

7 Tips for Choosing the Best Pulse Laser Cleaning Machine for Rust Removal

-

5 Best Techniques Using Aser Cleaning Machine to Effectively Remove Paint from Wood

-

Ultimate Guide to Choosing the Best Fiber Laser Welding Machine for Jewelry

-

Mastering the Best Optical Fiber Laser Cutting Machine: A Comprehensive Tutorial for Global Buyers

-

The Ultimate Guide to Choosing the Best Laser Welder for Your Mold Repair Needs

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top