What is the Importance of Industrial Laser Cleaning Machine in Modern Manufacturing

Table of Contents

- The Evolution of Industrial Cleaning Techniques in Manufacturing

- Key Advantages of Laser Cleaning Machines Over Traditional Methods

- Applications of Laser Cleaning in Various Industries

- How Laser Cleaning Enhances Product Quality and Sustainability

- The Economic Impact of Adopting Laser Cleaning Technology in Factories

- Future Trends and Innovations in Industrial Laser Cleaning Machines

- FAQS

- Conclusion

- Related Posts

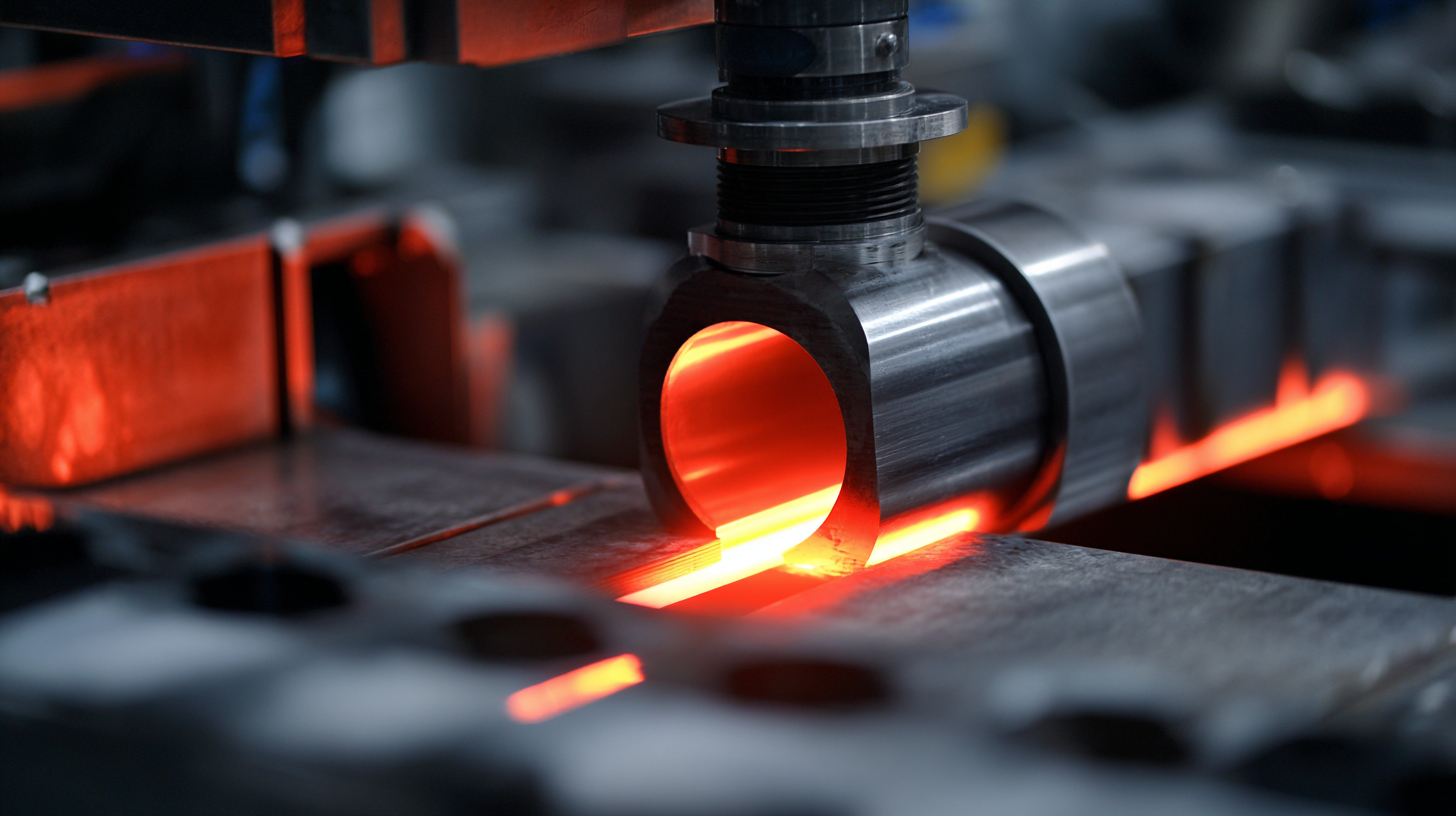

In today's rapidly evolving manufacturing landscape, the significance of the Industrial Laser Cleaning Machine cannot be overstated. As reported by industry analysts, the global laser cleaning market is expected to witness substantial growth, reaching approximately $1.5 billion by 2025, driven by the increasing demand for efficient and environmentally friendly cleaning solutions. Manufacturers like Maven Laser Automation Co., Ltd., established in 2008 in Shenzhen, China, are at the forefront of this transformation, providing advanced laser systems that enhance operational efficiency and reduce environmental impact.

The integration of laser cleaning technology in industrial processes not only ensures superior cleaning results but also minimizes downtime and operating costs, making it a vital asset in modern manufacturing practices. In this blog, we will explore the importance of Industrial Laser Cleaning Machines and how they can revolutionize manufacturing operations.

The Evolution of Industrial Cleaning Techniques in Manufacturing

The evolution of industrial cleaning techniques in manufacturing has undergone substantial transformation over the past few decades, fueled by the quest for efficiency and sustainability. Historically, methods such as sandblasting and chemical cleaning posed significant safety and environmental risks. However, the advent of industrial laser cleaning machines represents a paradigm shift, offering a cleaner, safer alternative. According to a report by Markets and Markets, the global laser cleaning market is projected to grow from USD 385 million in 2020 to USD 905 million by 2025, indicating a robust shift towards laser technology in manufacturing processes.

Laser cleaning technology employs high-intensity lasers to remove contaminants like rust, paint, and dirt without the need for harsh chemicals or abrasive materials. This not only ensures a safer workplace but also minimizes waste, aligning with the growing emphasis on green manufacturing practices. A study by the European Commission revealed that adopting cleaner technologies could reduce operational costs by up to 30%. The precision and efficiency of laser cleaning allow manufacturers to maintain high standards of cleanliness, ultimately leading to enhanced product quality and reduced downtime, which are crucial in today’s competitive market. As industrial laser cleaning continues to evolve, it is set to play an essential role in modern manufacturing strategies.

Key Advantages of Laser Cleaning Machines Over Traditional Methods

Industrial laser cleaning machines are transforming modern manufacturing by introducing efficiencies that traditional methods struggle to match. According to a recent report by Grand View Research, the global laser cleaning market is expected to reach USD 2.77 billion by 2025, driven by the increasing adoption of this technology due to its superior performance. Unlike conventional cleaning methods that often rely on harsh chemicals or abrasive techniques, laser cleaning utilizes focused light to remove contaminants, offering a more environmentally-friendly solution that reduces waste and minimizes the risk of damaging surfaces.

One of the key advantages of laser cleaning machines is their precision. The ability to target specific areas allows for selective removal of contaminants without impacting the substrate material. Research published in the Journal of Manufacturing Processes indicates that laser cleaning can achieve cleanliness levels of up to 99%, a significant improvement compared to traditional methods that often leave residues behind. Additionally, laser cleaning eliminates the need for drying times associated with wet cleaning processes, thus enhancing operational efficiency and reducing downtime in manufacturing environments. As industries increasingly prioritize sustainability and efficiency, the shift towards laser technologies in cleaning processes is undeniably on the rise.

Applications of Laser Cleaning in Various Industries

Industrial laser cleaning machines have revolutionized surface preparation in various sectors, offering precise solutions for the removal of contaminants like rust, paint, and other residues. In the automotive industry, for instance, a report by the International Journal of Advanced Manufacturing Technology noted that laser cleaning can improve surface quality by up to 80%, significantly enhancing adhesion for subsequent coatings. This efficiency translates to reduced material wastage and lower costs, reinforcing the laser's role in modern manufacturing practices.

In the aerospace sector, laser cleaning technology benefits from its ability to preserve underlying substrates while effectively removing surface impurities. According to a study by the Aerospace Industries Association, using laser cleaning can increase operational efficiency by up to 30% during maintenance cycles compared to traditional methods. Additionally, in the electronics industry, laser cleaning ensures that sensitive components remain intact, which is crucial for maintaining performance standards. As industries continue to adopt these advanced technologies, the applications of laser cleaning are set to expand, driving innovation and sustainability across the manufacturing landscape.

In the aerospace sector, laser cleaning technology benefits from its ability to preserve underlying substrates while effectively removing surface impurities. According to a study by the Aerospace Industries Association, using laser cleaning can increase operational efficiency by up to 30% during maintenance cycles compared to traditional methods. Additionally, in the electronics industry, laser cleaning ensures that sensitive components remain intact, which is crucial for maintaining performance standards. As industries continue to adopt these advanced technologies, the applications of laser cleaning are set to expand, driving innovation and sustainability across the manufacturing landscape.

How Laser Cleaning Enhances Product Quality and Sustainability

In modern manufacturing, laser cleaning technology has emerged as a pivotal innovation that significantly enhances product quality and sustainability. According to a report by MarketsandMarkets, the global market for laser cleaning equipment is projected to reach $1.4 billion by 2026, demonstrating a growing recognition of its benefits. One of the key advantages of laser cleaning is its ability to effectively remove contaminants without damaging base materials. This precision not only improves the performance and longevity of products but also minimizes the need for rework and waste, leading to more efficient manufacturing processes.

Moreover, the sustainability aspect of laser cleaning cannot be overlooked. Traditional cleaning methods often rely on harsh chemicals and generate considerable waste, both of which are detrimental to the environment. In contrast, laser cleaning utilizes light energy to achieve the desired results, relying solely on water or dry air as an auxiliary medium in some cases. Research from the International Journal of Advanced Manufacturing Technology highlights that laser cleaning can reduce waste generation by up to 90%, significantly contributing to green manufacturing initiatives. By adopting laser cleaning technologies, manufacturers can enhance product quality while simultaneously aligning with sustainable practices that reduce their ecological footprint.

The Importance of Industrial Laser Cleaning Machines in Modern Manufacturing

This chart illustrates the impact of industrial laser cleaning machines on product quality and sustainability in modern manufacturing. The data reflects improvements in various metrics due to the adoption of laser cleaning technology.

The Economic Impact of Adopting Laser Cleaning Technology in Factories

In modern manufacturing, the adoption of laser cleaning technology presents a transformative economic advantage for factories. Unlike traditional cleaning methods that rely on harsh chemicals or abrasive techniques, laser cleaning provides an efficient, eco-friendly solution. This not only reduces operational costs associated with material usage and waste management but also minimizes downtime, enabling quicker turnaround times in production cycles. By integrating laser cleaning systems into their processes, companies can improve product quality and extend the lifespan of machinery, leading to significant long-term savings.

Maven Laser Automation Co., Ltd., a leading manufacturer based in Shenzhen, China, exemplifies the potential of laser technology in industrial applications. Founded in 2008, Maven Laser specializes in delivering advanced automation solutions and laser systems tailored to enhance manufacturing efficiency. As factories increasingly turn to laser cleaning machines, they benefit from reduced labor costs and enhanced safety protocols, thus fostering a more sustainable manufacturing environment. The economic impact of such technological adoption is clear: investments in laser cleaning not only optimize production but also contribute to a more competitive market stance in the rapidly evolving industrial landscape.

Future Trends and Innovations in Industrial Laser Cleaning Machines

The advent of industrial laser cleaning machines marks a significant shift in modern manufacturing, driven by the demand for more efficient and environmentally friendly cleaning solutions. Future trends indicate that these machines will become more integrated with robotics and automation, enabling seamless workflow in manufacturing processes. As industries seek to enhance productivity, laser cleaning technology will play a crucial role in surface preparation, maintenance, and product lifecycle prolongation.

When considering an industrial laser cleaning machine, it is essential to keep a few tips in mind. First, assess the specific requirements of your manufacturing process to select the appropriate power and wavelength of the laser that suits your cleaning needs. Secondly, look for machines equipped with advanced monitoring systems that ensure consistent performance and reduce downtime. Emphasizing sustainability, future innovations may also include more energy-efficient models that utilize renewable energy sources, aligning manufacturing practices with global environmental goals.

As manufacturers explore these futuristic innovations, the focus will shift towards developing machines that are more user-friendly with enhanced safety features. Understanding the ongoing advancements in laser technology will empower businesses to optimize their cleaning processes, resulting in improved operational efficiency and reduced costs.

What is the Importance of Industrial Laser Cleaning Machine in Modern Manufacturing - Future Trends and Innovations in Industrial Laser Cleaning Machines

| Application | Industry | Advantages | Future Trend |

|---|---|---|---|

| Surface Preparation | Manufacturing | High precision, eco-friendly | Integration with robotics |

| Rust Removal | Automotive | Time-efficient, reduces waste | Advanced AI for automated cleaning |

| Coating Removal | Aerospace | Non-destructive, customizable | Smart sensors for precision |

| Deburring | Electronics | Improves surface finish, reduces labor | Higher efficiency through automation |

| Historical Restoration | Cultural Heritage | Gentle on surfaces, precise | Innovative laser technologies |

FAQS

: Historically, methods such as sandblasting and chemical cleaning were commonly used in manufacturing, but these posed significant safety and environmental risks.

Laser cleaning utilizes high-intensity lasers to remove contaminants without the need for harsh chemicals or abrasive materials, offering a safer and more environmentally-friendly solution compared to traditional methods.

Key advantages include precision in targeting specific contaminants, achieving cleanliness levels of up to 99%, no drying times required, and the elimination of harmful waste generated by traditional cleaning methods.

Laser cleaning improves product quality by effectively removing contaminants without damaging the base materials, which enhances product performance and longevity and minimizes the need for rework.

The global laser cleaning market is projected to grow significantly, from USD 385 million in 2020 to USD 905 million by 2025, indicating a robust shift towards laser technology in manufacturing processes.

Laser cleaning contributes to sustainability by reducing waste generation by up to 90%, relying mainly on light energy and minimal auxiliary materials, thereby aligning with green manufacturing practices.

Laser cleaning enhances operational efficiency by reducing downtime, as it eliminates the drying times associated with wet cleaning processes and allows for immediate processing after cleaning.

By eliminating the use of harsh chemicals and generating less hazardous waste, laser cleaning poses reduced environmental risks compared to traditional cleaning techniques.

The global market for laser cleaning equipment is projected to reach $1.4 billion by 2026, reflecting an increased recognition of its benefits in manufacturing.

Adopting cleaner technologies like laser cleaning can reduce operational costs by up to 30%, providing economic benefits alongside improved sustainability and efficiency.

Conclusion

Industrial Laser Cleaning Machines have revolutionized the manufacturing landscape, marking a significant evolution in industrial cleaning techniques. Compared to traditional cleaning methods, laser cleaning offers key advantages such as enhanced precision, reduced environmental impact, and decreased operational costs. These systems are highly effective in various applications, from automotive to aerospace and beyond, providing manufacturers with a viable solution that not only improves product quality but also promotes sustainability.

As industries continue to adopt this advanced technology, the economic impact is becoming increasingly evident, leading to improved efficiency and reduced downtime. Looking ahead, innovations in Industrial Laser Cleaning Machines promise to further enhance their capabilities, solidifying their role as essential tools in modern manufacturing. At Maven Laser Automation Co., Ltd., we are proud to contribute to this transformation, delivering state-of-the-art laser systems designed to meet the evolving needs of the market.

Related Posts

-

What is a Laser Cleaning Head With Beam Adjustment and How Does It Work

-

7 Tips for Choosing the Best Pulse Laser Cleaning Machine for Rust Removal

-

Unmatched Quality in Laser Cleaning for Wood Trim from China's Leading Manufacturer

-

Key Factors to Identify Reliable Manufacturers for the Best 3000w Handheld Laser Cleaner

-

Unmatched Manufacturing Excellence in China Featuring the Best Laser Cleaning Head With Advanced Operating Modes

-

How to Effectively Use Portable 1000w Laser Cleaner for Industrial Applications

Blog Tags:

Olivia

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top