What is the Innovation Behind 100w Laser Jewelry Welder Technology

Table of Contents

- The Evolution of Laser Welding Technology in Jewelry Making

- Understanding the 100W Laser Welder: Key Features and Benefits

- How 100W Laser Welders Revolutionize Jewelry Design and Repair

- Comparative Analysis: 100W Laser Welder vs. Traditional Welding Methods

- Real-World Applications of 100W Laser Welders in the Jewelry Industry

- FAQS

- Conclusion

- Related Posts

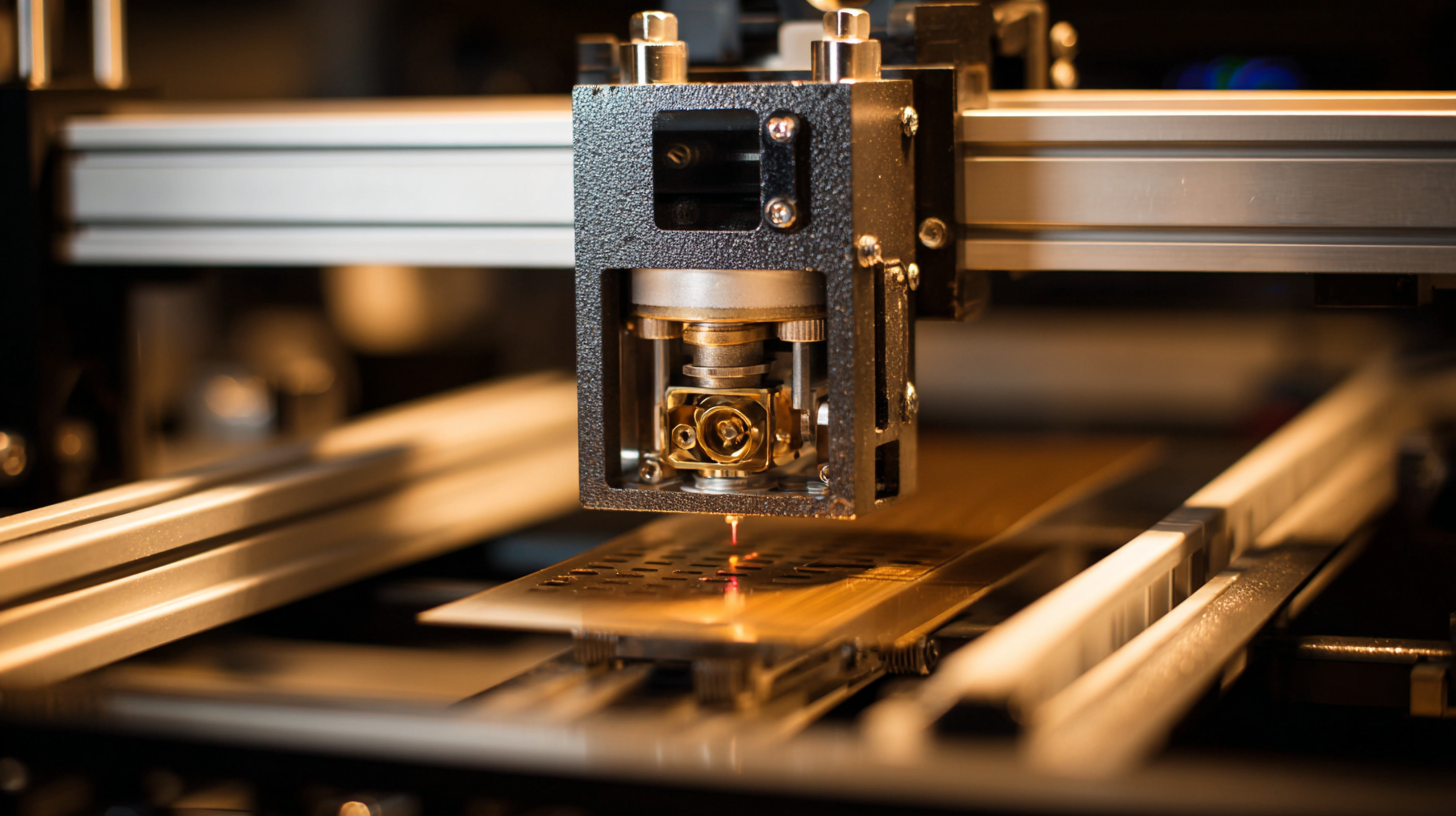

In recent years, the jewelry manufacturing industry has witnessed significant advancements in technology, particularly with the introduction of the 100w Laser Jewelry Welder. This innovative tool enhances precision and efficiency in jewelry assembly and repair, addressing the artisanal need for high-quality craftsmanship. According to a market report by Research and Markets, the global laser welding market is projected to reach $14.76 billion by 2027, driven by continuous innovations and increasing applications across various industries, including jewelry-making. At the forefront of this technological evolution is Maven Laser Automation Co., Ltd., a prominent manufacturer based in Shenzhen, China. Established in 2008, Maven Laser specializes in advanced laser systems and automation solutions, providing cutting-edge technology that empowers jewelers to create intricate designs with unparalleled accuracy. The 100w Laser Jewelry Welder exemplifies this innovation, making it an indispensable tool for modern jewelers aiming to elevate their craftsmanship and efficiency.

The Evolution of Laser Welding Technology in Jewelry Making

The evolution of laser welding technology in jewelry making has significantly transformed the way artisans create intricate designs. Laser welding, which gained momentum in the mid-1990s, has seen remarkable advancements over the years. According to a report from IBISWorld, the global jewelry manufacturing industry is projected to reach $300 billion by 2025, with laser welding playing a pivotal role in its growth. The precision and effectiveness of 100w laser jewelry welders allow jewelers to bond materials with minimal heat, reducing the risk of damage to delicate pieces and ensuring higher quality craftsmanship.

Moreover, the integration of advanced laser technology has streamlined production processes. A study published by the American Journal of Manufacturing revealed that laser welding techniques can increase efficiency by up to 30% compared to traditional methods. This time-saving aspect not only enhances productivity but also allows jewelers to explore more complex designs that were previously unattainable. As laser welding continues to evolve, its applications in jewelry making become increasingly versatile, enabling craftsmen to push the boundaries of creativity while maintaining durability and aesthetic appeal.

Innovation in 100W Laser Jewelry Welder Technology

This chart illustrates key performance metrics associated with the innovation in 100W laser jewelry welder technology, demonstrating the combination of power output, speed, cost efficiency, heat affected zone, and user adoption rates that define its advancement in jewelry making.

Understanding the 100W Laser Welder: Key Features and Benefits

The 100W laser jewelry welder technology has revolutionized the way jewelers approach metal joining processes. One of its key features is the precision it offers, allowing jewelers to work on intricate designs without the risk of damaging surrounding materials. The focused beam of the laser can melt metal with pinpoint accuracy, enabling seamless connections between different metal parts. This level of control makes it ideal for repairing delicate pieces or creating complex designs, where traditional methods might fail or result in an uneven finish.

Another significant benefit of the 100W laser welder is its speed and efficiency. The technology allows for rapid welding, significantly reducing production times. Jewelers can complete tasks that once took hours in mere minutes, leading to increased productivity. Additionally, the low heat input minimizes distortion and reduces the risk of warping metals, which is crucial when working with precious materials. As a result, the investment in a 100W laser welder enhances not only the quality of craftsmanship but also the overall workflow of jewelry production.

How 100W Laser Welders Revolutionize Jewelry Design and Repair

The advancements in laser welding technology, particularly the innovative 100W laser welders, have significantly transformed jewelry design and repair. These powerful tools allow jewelers to execute intricate designs with precision and minimal heat distortion, which is particularly crucial for delicate materials like gold and platinum. A recent industry report highlights a staggering growth rate of approximately 15% in the adoption of laser technologies within the jewelry sector. This shift not only enhances craftsmanship but also ensures that repairs are seamless, preserving the integrity of timeless pieces.

Moreover, the integration of 3D printing in jewelry production exemplifies this revolution further. As jewelers embrace direct metal 3D printing, they are capable of creating complex designs that were previously unattainable with traditional methods. This fusion of 3D printing and laser welding allows for greater creativity and efficiency. While there is a concern about losing traditional craftsmanship, the evolution of technology is enabling artisans to enhance their work without compromising artistic expression. Techniques like laser engraving are also gaining traction, allowing for personalization of pieces with intricate details that cater to modern consumers' tastes. The jewelry industry is poised at a unique intersection of innovation and tradition, paving the way for a more dynamic future.

Comparative Analysis: 100W Laser Welder vs. Traditional Welding Methods

The emergence of 100W laser jewelry welder technology marks a significant breakthrough in the jewelry manufacturing industry, particularly when compared to traditional welding methods. Laser welders utilize focused laser beams to create precise and strong joints in metal pieces, offering enhanced control over the welding process. This results in cleaner seams and reduced heat-affected zones, which is crucial for delicate materials often used in jewelry.

Industry analysis indicates that the fiber laser market is expected to grow significantly, with projections suggesting a substantial shift towards low-power outputs, particularly within the range of 100W. This trend highlights the shift in preference from traditional welding methods, which often produce larger heat dispersions and can compromise the integrity of finer pieces. By utilizing 100W laser technology, jewelers can achieve higher precision and efficiency, leading to increased productivity and reduced material waste.

Comparative studies reveal that the advantage of using a 100W laser welder lies in its ability to operate at lower power while still delivering powerful results. The latest data suggests that the fiber laser segment, specifically low-power solutions, will dominate the market share by 2032, confirming a growing confidence in laser technology as a reliable alternative to conventional methods. This transformation in jewelry welding not only reflects advancements in technology but also the evolving needs of the industry for precision and efficiency.

Real-World Applications of 100W Laser Welders in the Jewelry Industry

The 100W laser welder technology is transforming the jewelry industry with its precision and efficiency, making it a game-changer for jewelers. One notable application of this innovation is its ability to repair delicate pieces without compromising their integrity. Jewelers can now perform intricate repairs on fine jewelry, such as reattaching small stones or reinforcing solder joints, all while minimizing heat exposure to surrounding settings. This helps preserve the overall quality and craftsmanship of each piece, ensuring that jewelry maintains its beauty for years to come.

Moreover, the 100W laser welder facilitates creativity and versatility in design. Jewelers are leveraging this technology to create unique custom pieces that were once challenging to produce. With the ability to work on various metals and intricate designs, artisans can push the boundaries of traditional jewelry-making. As visible in the story of Tracy Beamon, who embodies the spirit of resilience while welding happiness into each creation, this technology not only strengthens the craft but also enriches the emotional narratives behind jewelry. The impact of 100W laser welders is profound, ensuring both quality and artistry flourish in the jewelry world.

FAQS

: Laser welding technology involves using focused laser beams to bond materials in jewelry making, leading to intricate designs and high-quality craftsmanship.

Laser welding technology gained momentum in the mid-1990s and has undergone significant advancements since then.

Laser welding offers enhanced precision and control, resulting in cleaner seams and reduced heat-affected zones, which is essential for delicate materials used in jewelry.

A 100W laser welder allows jewelers to achieve higher precision, increase efficiency by up to 30%, and reduce material waste compared to conventional welding methods.

Laser welding technology has transformed production processes, enabling artisans to explore complex designs while maintaining durability and aesthetic appeal, contributing to industry growth projected at $300 billion by 2025.

Low-power fiber laser technology, particularly 100W solutions, is gaining preference due to its ability to operate effectively at lower power levels, ensuring high precision and reduced heat dispersions for finer pieces.

The fiber laser market is projected to grow significantly, with low-power solutions expected to dominate market share by 2032.

By streamlining production processes, laser welding techniques can enhance productivity, allowing jewelers to focus on more complex and creative designs that were previously unattainable.

Studies show that laser welding can increase efficiency by up to 30% compared to traditional methods, making it a more effective option for jewelry manufacturing.

Advancements in laser welding technology reflect the evolving needs of the jewelry industry for precision and efficiency, indicating a significant transformation in how jewelry is produced.

Conclusion

The blog titled "What is the Innovation Behind 100W Laser Jewelry Welder Technology" explores the transformative impact of laser welding technology in the jewelry industry. It outlines the evolution of laser welding, highlighting how the 100W Laser Jewelry Welder stands out with its advanced features and numerous benefits. This technology not only enhances the design and repair processes of jewelry but also presents a significant improvement when compared to traditional welding methods.

Furthermore, the blog discusses real-world applications of the 100W Laser Jewelry Welder, showcasing how it is revolutionizing craftsmanship in the jewelry sector. As a leading manufacturer in laser systems, Maven Laser Automation Co., Ltd. plays a crucial role in advancing this technology, enabling jewelers to achieve precision and efficiency in their work.

Related Posts

-

How to Effectively Use Portable 1000w Laser Cleaner for Industrial Applications

-

How to Select the Best Fiber Laser Cutting Machine Manufacturers: Key Industry Insights

-

Top Strategies for Choosing the Best Co2 Laser Engraver for Your Business

-

Exploring Top Alternatives to the Best Fiber Laser Machine for Your Business Needs

-

Excellence in Manufacturing with the Best Mini Fiber Laser Machine from China to the World

-

Key Factors to Identify Reliable Manufacturers for the Best 3000w Handheld Laser Cleaner

Blog Tags:

Olivia

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top