Innovative Applications of Laser Cleaner Machines in Industrial Maintenance

Table of Contents

- Understanding the Technology Behind Laser Cleaner Machines in Industrial Settings

- Key Benefits of Utilizing Laser Cleaners for Industrial Maintenance Tasks

- Step-by-Step Guide to Implementing Laser Cleaning Solutions in Factories

- Real-World Case Studies: Success Stories of Laser Cleaners in Industry

- Best Practices for Maintaining and Operating Laser Cleaner Machines

- Future Trends: Innovations in Laser Cleaning for Enhanced Industrial Maintenance

- FAQS

- Conclusion

- Related Posts

In the rapidly evolving landscape of industrial maintenance, the utilization of advanced technologies has become imperative for enhancing efficiency and sustainability. One such innovation making waves in the sector is the Laser Cleaner Machine, which offers a highly effective and eco-friendly solution for contamination removal across various surfaces. As companies strive to maintain high operational standards while minimizing environmental impact, the Laser Cleaner Machine stands out as a transformative tool. Maven Laser Automation Co., Ltd., a pioneering manufacturer of laser systems and professional automation solutions based in Shenzhen, China, has been at the forefront of this technological advancement since its inception in 2008. With a rich history in laser market design, production, and sales, Maven Laser is committed to providing cutting-edge solutions that not only improve maintenance processes but also align with the growing demand for sustainable operational practices.

Understanding the Technology Behind Laser Cleaner Machines in Industrial Settings

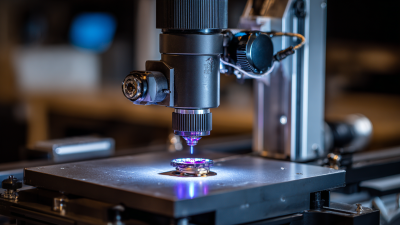

Laser cleaner machines are revolutionizing industrial maintenance by utilizing advanced laser technology to remove contaminants from surfaces. These machines operate by emitting high-intensity laser beams that ablate materials such as rust, paint, and dirt without damaging the underlying substrate. This precision allows for thorough cleaning in a variety of industrial environments, including manufacturing plants and automotive workshops. The technology also promotes sustainability, as it minimizes the need for harsh chemical cleaners and reduces waste.

Tips for using laser cleaner machines effectively include ensuring proper training for operators to maximize safety and efficiency. Always conduct a thorough assessment of the surface material to select the appropriate laser settings. Additionally, regular maintenance of the laser equipment is essential to maintain its performance and longevity, ensuring that it continues to operate at optimal levels.

As industries strive for both cleanliness and efficiency, understanding the technology behind laser cleaner machines becomes crucial. These devices not only enhance the maintenance process, but they also pave the way for new applications in various sectors, highlighting the importance of embracing innovative solutions in industrial settings.

Key Benefits of Utilizing Laser Cleaners for Industrial Maintenance Tasks

The adoption of laser cleaner machines in industrial maintenance is revolutionizing the way organizations approach cleaning and maintenance tasks. One of the key benefits of utilizing laser cleaners is their ability to significantly reduce environmental impact. Unlike traditional cleaning methods that often rely on harsh chemicals, laser cleaning offers a sustainable alternative by using high-powered beams of light to remove contaminants like rust or paint without generating toxic waste. This not only promotes a safer work environment but also aligns with the growing demand for eco-friendly practices in industrial sectors.

Additionally, laser cleaning technology enhances operational efficiency by automating maintenance processes. Companies can achieve precise and consistent results at a faster rate, leading to improved productivity and reduced downtime. The ongoing advancements in laser technology, including the recent successful trials for applications such as ship hull rust removal, demonstrate how these systems can transform maintenance tasks across various industries. As the laser cleaning market continues to grow, its integration into maintenance operations is likely to drive significant improvements in both cleanliness and efficiency.

Step-by-Step Guide to Implementing Laser Cleaning Solutions in Factories

To effectively implement laser cleaning solutions in factories, it is essential to follow a methodical step-by-step approach. First, assess the specific cleaning needs of your facility, identifying areas with significant contamination or residue. This evaluation will help determine the type of laser cleaner machine that best suits the application, whether it’s for rust removal, surface preparation, or removing paint.

Engaging with suppliers for demonstrations can also clarify capabilities and set realistic expectations.

Once the appropriate equipment is selected, the next step involves training the workforce. This training should cover both operational procedures and safety protocols, as handling laser equipment requires adherence to specific safety standards. Operators should become familiar with the machine’s functionalities, maintenance schedules, and the best practices for optimizing cleaning efficiency. Following this, pilot testing in a controlled environment allows for adjustments based on real-time feedback, ensuring that the implementation scale-up will be seamless and effective while minimizing any potential production downtime.

Real-World Case Studies: Success Stories of Laser Cleaners in Industry

Laser cleaner machines have revolutionized industrial maintenance, showcasing their effectiveness through various real-world case studies. One notable success story involves a manufacturing facility that faced persistent issues with rust and corrosion on metal components. By integrating a laser cleaning solution, they experienced a dramatic reduction in cleaning time and costs, allowing for more efficient production schedules. The laser technology not only eradicated contaminants without damaging the underlying materials but also minimized waste production, aligning with sustainable practices.

When considering implementing laser cleaners, here are a few tips: First, assess the specific cleaning needs of your operation to determine the appropriate laser type and power. Second, ensure proper training for personnel; effective usage directly correlates with the maintenance and longevity of the equipment. Lastly, consider running pilot tests in smaller areas before scaling up, as this will help identify any unforeseen challenges while maximizing your return on investment.

Another example comes from the automotive industry, where a laser cleaner was deployed to restore engine parts affected by carbon buildup. The results were impressive, with a noticeable enhancement in performance and a reduction in overall downtime. This case underscores the versatility of laser cleaning technology, which can be tailored for various applications across different sectors.

Innovative Applications of Laser Cleaner Machines in Industrial Maintenance - Real-World Case Studies

| Industry | Application | Results Achieved | Cost Savings (%) | Reduction in Downtime (Hours) |

|---|---|---|---|---|

| Automotive | Removal of paint and rust | Improved surface quality; ready for repainting | 30% | 5 |

| Aerospace | Cleaning of turbine blades | Enhanced performance and efficiency | 25% | 3 |

| Manufacturing | Deburring of metal components | Increased production speed | 20% | 4 |

| Marine | Hull cleaning | Improved fuel efficiency | 15% | 10 |

| Construction | Removal of concrete residues | Increased lifespan of equipment | 10% | 6 |

Best Practices for Maintaining and Operating Laser Cleaner Machines

When it comes to maintaining and operating laser cleaner machines, best practices are crucial for maximizing their efficacious use in industrial maintenance. According to a report by MarketsandMarkets, the global market for laser cleaning is expected to reach USD 1.1 billion by 2025, growing at a CAGR of 5.8%. This surge indicates not only the increasing adoption of laser cleaning technology but also underscores the necessity for effective operational strategies to ensure longevity and efficiency.

One essential practice includes regular maintenance checks on the laser system, focusing on components such as the lens and coolant systems. Keeping these parts clean and functional can prevent performance degradation and enhance precision during cleaning operations. Moreover, operators should undergo thorough training to familiarize themselves with the machine's capabilities and safety protocols.

Data from the Laser Institute of America suggests that proper operator training can improve productivity by up to 30%, reducing downtime and increasing the safety of the workplace. By implementing these best practices, businesses can optimize their laser cleaning operations, contributing to smoother maintenance processes and reduced operational costs.

Future Trends: Innovations in Laser Cleaning for Enhanced Industrial Maintenance

The innovative applications of laser cleaning technology are transforming industrial maintenance, offering a glimpse into the future trends of enhanced maintenance practices. Recent advancements have highlighted the development of portable laser cleaning machines, which improve equipment flexibility and ease of use. This new design, featuring easy-to-operate wheels and hinge components, ensures safe mobility while maintaining device stability. Such innovations not only enhance operational efficiency but also reflect the growing demand for versatile maintenance solutions in a dynamic industrial landscape.

According to market reports, the global laser cleaning system market is projected to grow significantly, from a value of $721.2 million in 2025 to an estimated $971.9 million by 2033, with a compound annual growth rate (CAGR) of 3.8%. This growth underscores the industrial sector's shift towards laser cleaning as a preferred method for efficient surface preparation and maintenance. As highlighted in discussions at recent industry forums, laser cleaning is increasingly recognized as a leading trend in industrial maintenance, showcasing its potential to revolutionize cleaning processes through enhanced efficiency and reduced environmental impact.

FAQS

: Laser cleaner machines are used to remove contaminants from surfaces, such as rust, paint, and dirt, without damaging the underlying material, making them ideal for various industrial environments.

Laser cleaning minimizes the need for harsh chemical cleaners and reduces waste, offering a more sustainable alternative to traditional cleaning methods that can produce toxic waste.

Operators should undergo proper training to understand operational procedures and safety protocols, should assess the surface material to select the appropriate laser settings, and conduct regular maintenance on the equipment.

Laser cleaners significantly reduce environmental impact, enhance operational efficiency by automating processes, and provide precise and consistent cleaning results at a faster rate.

Companies should start by assessing their specific cleaning needs, selecting the appropriate laser cleaning equipment, training the workforce, and conducting pilot testing to ensure effective implementation.

Consider the specific cleaning applications required, such as rust removal or surface preparation, and engage with suppliers for demonstrations to understand the capabilities of different machines.

Regular maintenance is essential to sustain the performance and longevity of the laser cleaning equipment, ensuring it operates at optimal levels over time.

Training is crucial for operators to familiarize themselves with the machine functionalities, maintenance schedules, and best practices, which in turn enhances safety and cleaning efficiency.

Yes, laser cleaning technology has applications across various sectors, including manufacturing and automotive, as it improves maintenance processes and meets evolving industry demands.

Conduct pilot testing in a controlled environment to gather real-time feedback and make necessary adjustments, ensuring a seamless and effective scale-up while minimizing production downtime.

Conclusion

In recent years, the innovative applications of Laser Cleaner Machines have transformed industrial maintenance practices. These advanced machines leverage cutting-edge technology to provide efficient cleaning solutions, significantly reducing the need for traditional chemical methods. Understanding the mechanisms behind laser cleaning highlights the key benefits, such as improved safety, enhanced precision, and cost-effectiveness in maintenance tasks.

Maven Laser Automation Co., Ltd., a pioneer in the laser systems market, emphasizes the importance of implementing these solutions systematically in factories. Their success stories, drawn from real-world case studies, showcase how Laser Cleaner Machines have revolutionized operations across industries. Furthermore, best practices for operating and maintaining these machines ensure optimal performance, while future trends indicate continued innovations that will further streamline industrial maintenance processes.

Related Posts

-

5 Essential Tips for Optimizing Your Laser Cleaning Head Rack Performance

-

Discover the Finest Laser Cleaner: Premium Quality from China's Leading Manufacturing Factory

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

Maximizing Value with Best Portable Laser Cleaner With Battery Through Cost Effective Maintenance and Support

-

7 Best Reasons to Invest in a Rust Cleaning Laser Machine

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top