Why Invest in Industrial Laser Equipment for Enhanced Precision and Efficiency?

Table of Contents

- Overview of Industrial Laser Equipment and Its Applications

- The Importance of Precision in Modern Manufacturing Processes

- Benefits of Enhanced Efficiency with Laser Technology

- Key Features of Industrial Laser Equipment

- Comparative Analysis: Lasers vs. Traditional Cutting Tools

- Cost-Effectiveness of Investing in Laser Solutions

- Future Trends in Industrial Laser Technology and Applications

- FAQS

- Conclusion

- Related Posts

In recent years, the adoption of Industrial Laser Equipment has surged, driven by the demand for enhanced precision and efficiency across various manufacturing sectors. According to a report by MarketsandMarkets, the global industrial laser market is projected to reach $13.2 billion by 2026, with an annual growth rate of over 5%. This staggering growth underscores the critical role that advanced laser technologies play in shaping the future of manufacturing, from automotive to electronics.

Experts like Dr. Michael Schmid, a renowned authority in the field of laser technology, emphasize the transformative impact of these tools: "Investing in Industrial Laser Equipment allows manufacturers to achieve unparalleled accuracy in their processes, reducing waste and increasing production efficiency." This sentiment captures the essence of why industries are increasingly pivoting towards laser solutions — the ability to meet the high-precision demands of modern manufacturing while also optimizing operational efficiency.

As industries continue to evolve, the integration of Industrial Laser Equipment signifies not just an upgrade in technology but a strategic move towards sustainable manufacturing practices. By harnessing state-of-the-art laser systems, manufacturers can improve productivity, enhance product quality, and ultimately drive their competitive edge in the global market.

Overview of Industrial Laser Equipment and Its Applications

Industrial laser equipment has become a cornerstone in various manufacturing processes, known for its precision and efficiency across multiple applications. In sectors such as automotive, aerospace, and electronics, lasers are utilized for cutting, welding, engraving, and marking materials with exceptional accuracy. According to a market research report by MarketsandMarkets, the global industrial laser market is projected to grow from USD 4.3 billion in 2020 to USD 7.3 billion by 2025, highlighting the increasing demand for advanced technologies that elevate production standards.

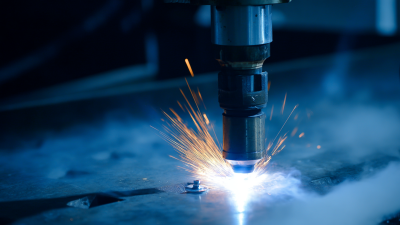

One significant application of industrial lasers is in metal fabrication, where they facilitate the cutting of complex shapes with minimal waste. Lasers provide a non-contact method, which not only reduces the likelihood of material distortion but also enhances the overall quality of the final product. Additionally, in the electronics manufacturing sector, laser marking has taken precedence due to its ability to produce high-resolution codes and graphics that comply with stringent regulatory standards.

Tip: When considering investing in industrial laser equipment, assess the specific needs of your manufacturing process to ensure you choose the right type of laser technology, whether fiber, CO2, or solid-state, to maximize productivity and reduce operational costs. Furthermore, training your workforce to efficiently handle these advanced tools can further optimize their use and ensure safety standards are met.

The Importance of Precision in Modern Manufacturing Processes

In modern manufacturing processes, precision is not merely a luxury but a fundamental requirement. The rise of industrial laser equipment has revolutionized how manufacturers approach the quest for precision. With the ability to cut, engrave, and mark materials with incredible accuracy, lasers ensure that components meet the strict tolerances needed for high-quality production. This level of precision leads to fewer errors, less waste, and enhanced product reliability, ultimately contributing to a more efficient manufacturing workflow.

Tips for achieving enhanced precision include investing time in proper setup and calibration of laser equipment. Regular maintenance checks can help prevent malfunctions and ensure that the laser operates at optimal levels. Furthermore, conducting thorough training sessions for operators will reduce human error and facilitate a better understanding of the technology's capabilities. Emphasizing a culture of precision throughout the organization can ultimately lead to improved outcomes and customer satisfaction.

Incorporating industrial laser technology also opens up opportunities for innovation. As manufacturers learn to harness the full potential of lasers, they can explore new designs and applications that were previously unattainable. This adaptability to newer technology empowers businesses to stay competitive in a rapidly evolving market.

Benefits of Enhanced Efficiency with Laser Technology

The adoption of laser technology in industrial applications has revolutionized the way manufacturers approach precision and efficiency. One of the key benefits of enhanced efficiency with laser equipment is its ability to perform high-speed operations without compromising accuracy. Unlike traditional cutting or engraving methods, lasers can execute intricate designs and patterns at remarkable speeds, significantly reducing production times while maintaining the integrity of the material. This level of precision minimizes waste and maximizes resource utilization, leading to cost savings and improved overall productivity.

Additionally, laser technology offers unparalleled flexibility across various materials, making it adaptable to multiple manufacturing processes. Whether it’s cutting metal, engraving wood, or marking plastics, the versatile nature of lasers allows for quick adjustments and reconfigurations, accommodating different project requirements with ease. This adaptability not only streamlines operations but also enhances the capacity for innovation, enabling manufacturers to explore new design possibilities and respond swiftly to market demands. By integrating laser technology, businesses can optimize their workflows and refine their production processes, further driving efficiency in their operations.

Key Features of Industrial Laser Equipment

Industrial laser equipment is equipped with several key features that contribute significantly to enhanced precision and efficiency in manufacturing processes. One of the most notable features is the high level of accuracy that lasers provide. With their ability to focus on very small areas, industrial lasers can achieve intricate cuts and engravings that are often impossible with traditional cutting tools. This precision minimizes material waste and ensures that products meet tight tolerance levels, which is particularly crucial in industries such as automotive and aerospace.

Another important aspect of industrial laser equipment is its versatility. These systems can be used for a variety of applications, including cutting, welding, marking, and engraving, allowing manufacturers to streamline their operations while reducing the need for multiple machines. Furthermore, modern laser equipment often comes with advanced software that enables automation, facilitating quicker setup times and improved workflow. This integration of technology not only enhances operational efficiency but also aids in maintaining high-quality standards across different production stages.

Comparative Analysis: Lasers vs. Traditional Cutting Tools

In today's manufacturing landscape, choosing the right cutting tools is crucial for achieving precision and efficiency. Traditional cutting tools, while reliable, often face limitations in terms of accuracy and material versatility. For instance, mechanical cutting processes can result in rough edges and increased material waste, as they rely on physical contact to remove material. This method not only increases the risk of tool wear but also prolongs setup times and reduces overall productivity.

In contrast, laser cutting technology offers significant advantages over traditional methods. By utilizing focused beams of light, lasers can cut through various materials with outstanding precision and minimal thermal distortion. This non-contact method eliminates the risk of tool wear and allows for intricate designs that would be challenging or impossible to achieve with conventional tools. Moreover, lasers operate at high speeds, which translates to faster production times and reduced costs in the long run. As industries continue to evolve, understanding the comparative benefits of laser equipment over traditional cutting tools is essential for any organization seeking to enhance its manufacturing capabilities.

Cost-Effectiveness of Investing in Laser Solutions

Investing in industrial laser equipment presents a compelling case for businesses looking to enhance both precision and efficiency in their operations. The cost-effectiveness of laser solutions is particularly noteworthy, as these technologies offer substantial long-term savings when compared to traditional methods. With lasers, the need for extensive tooling is minimized, reducing initial setup costs. Their precision significantly decreases material wastage, ensuring that every component produced meets exact specifications and reduces the frequency of costly reworks.

Moreover, laser equipment often operates at higher speeds without compromising accuracy, which can lead to increased throughput for manufacturing processes. This boost in productivity not only allows businesses to meet tighter deadlines but also minimizes labor costs by reducing the time workers spend on tasks. As a result, organizations can allocate resources more effectively and invest in other areas of growth. The energy efficiency of laser systems further contributes to operational savings, lowering utility costs and enhancing overall sustainability efforts. In the long run, the initial investment in industrial laser equipment proves to be a strategic move that supports both financial and operational objectives.

Future Trends in Industrial Laser Technology and Applications

The future of industrial laser technology is poised for significant advancements, driven by the need for higher precision and efficiency across various applications. As industries strive to improve productivity, lasers are becoming increasingly vital in processes such as cutting, welding, and engraving. Emerging technologies, such as fiber lasers and ultrafast laser systems, promise to enhance performance by delivering higher energy at focused points, thereby increasing accuracy and minimizing waste material.

Moreover, the integration of automation and artificial intelligence with laser systems is set to transform operational capabilities. Smart laser systems can adapt dynamically to changing conditions and materials, optimizing their performance in real-time. This not only improves the quality of outputs but also reduces downtime and increases throughput. As manufacturers continue to embrace Industry 4.0 principles, the synergy of laser technology with IoT (Internet of Things) will enable unprecedented levels of connectivity and data sharing, leading to more informed decision-making and streamlined production processes.

FAQS

: Industrial laser equipment is primarily utilized in cutting, welding, engraving, and marking materials in sectors such as automotive, aerospace, and electronics.

Lasers facilitate the cutting of complex shapes with minimal waste and provide a non-contact method that reduces material distortion while enhancing the overall product quality.

The global industrial laser market is projected to grow from USD 4.3 billion in 2020 to USD 7.3 billion by 2025, indicating an increasing demand for advanced technologies in manufacturing.

Precision is crucial because it ensures components meet strict tolerances, leading to fewer errors, reduced waste, enhanced product reliability, and a more efficient manufacturing workflow.

Tips include investing in proper setup and calibration of equipment, conducting regular maintenance checks, providing thorough training for operators, and promoting a culture of precision throughout the organization.

Proper training helps reduce human error, enhances operators' understanding of the technology's capabilities, and ensures safety standards are met, which optimizes the use of laser equipment.

Incorporating industrial laser technology allows manufacturers to explore new designs and applications that were previously unattainable, helping them to stay competitive in a rapidly evolving market.

Manufacturers should consider their specific needs and choose the right type of laser technology, such as fiber, CO2, or solid-state lasers, to maximize productivity and reduce operational costs.

Conclusion

Industrial Laser Equipment plays a pivotal role in modern manufacturing, delivering unparalleled precision and efficiency across various applications. As industries increasingly prioritize accuracy, the importance of precision in manufacturing processes cannot be overstated. Enhanced efficiency is another significant benefit, as laser technology optimizes production timelines and reduces waste, leading to better resource management.

Key features of industrial laser equipment, including speed, versatility, and low maintenance, further distinguish it from traditional cutting tools. A comparative analysis highlights the superior performance of lasers, making them a cost-effective investment despite the initial outlay. Looking ahead, the future trends in industrial laser technology promise even greater advancements, ensuring ongoing relevance in an evolving manufacturing landscape. Investing in Industrial Laser Equipment ultimately aligns with the goals of modern production, fostering innovation and competitiveness.

Related Posts

-

Future Market Trends for Best Fiber Laser Engraving Machines Towards 2025 with Real World Applications

-

Mastering Efficiency: Innovative Approaches to Optimize Your Best Laser Welding Machine Operations

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

-

Mastering Laser Welder Cutter Cleaner Techniques for Optimal Performance and Efficiency in Your Workshop

-

2025 Top 10 Laser Welding Robots: Revolutionizing Industrial Automation

-

2025 Top Laser Welder Innovations for Precision and Efficiency

Blog Tags:

Olivia

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top