Top Jewelry Welding Machines for Professional and DIY Jewelers in 2023

Table of Contents

- Top Features to Consider in Jewelry Welding Machines for 2023

- Understanding the Different Types of Jewelry Welding Machines

- Comparison of Top Brands in Jewelry Welding Machines for Professionals

- Key Specifications and Performance Metrics for DIY Jewelers

- Cost Analysis: Budget vs. Premium Jewelry Welding Machines

- Safety Standards and Guidelines for Operating Welding Machines

- Future Trends in Jewelry Welding Technology for Professionals

- FAQS

- Conclusion

- Related Posts

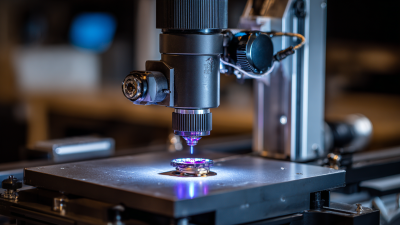

In the ever-evolving world of jewelry making, the integration of cutting-edge technology has dramatically transformed the crafting process. The rise of the Jewelry Welding Machine has particularly made waves among both professional and DIY jewelers, providing a reliable solution for creating intricate designs with precision and efficiency. Industry expert Robert Johnson, a renowned jeweler and educator, asserts, "The right Jewelry Welding Machine can elevate not only the quality of your pieces but also the creativity at your fingertips."

As we explore the top Jewelry Welding Machines for 2023, it is crucial to consider the factors that distinguish these machines in terms of functionality, ease of use, and adaptability for various projects. Whether you are a seasoned professional aiming to enhance your production capabilities or a hobbyist seeking to expand your crafting skills, the right welding machine can be a game-changer.

This article will delve into the features, benefits, and user experiences of the leading Jewelry Welding Machines on the market, aimed at providing invaluable insights for jewelers looking to invest in this essential equipment. With advancements in technology continually reshaping the landscape of jewelry making, understanding how to select the best machine is more important than ever.

Top Features to Consider in Jewelry Welding Machines for 2023

When choosing a jewelry welding machine in 2023, several key features can significantly enhance both professional and DIY jewelry-making experiences. First and foremost, the power output of the machine determines its effectiveness in welding various materials. Machines with adjustable power settings provide versatility, allowing jewelers to work with delicate materials, such as gold and silver, as well as more robust metals. This adaptability is essential for achieving precise welds without compromising the integrity of the components.

Another crucial aspect to consider is the type of welding technology employed by the machine. Pulse arc welding and laser welding are popular choices, each offering distinct advantages. Pulse arc welding, for instance, is known for its ability to create strong, clean welds in tight spaces, making it ideal for intricate designs. On the other hand, laser welding provides exceptional precision and minimal thermal distortion, which is particularly beneficial for repairs and complex assemblies. Additionally, features like built-in safety mechanisms, user-friendly interfaces, and portability options can greatly enhance the usability and effectiveness of a jewelry welding machine, catering to both skilled artisans and hobbyists.

Understanding the Different Types of Jewelry Welding Machines

When selecting a jewelry welding machine, it is essential to understand the various types available on the market and their specific applications. Jewelry welding machines primarily fall into three categories: laser welders, resistance welders, and TIG welders. Laser welders utilize focused beams of light to join metal pieces, providing high precision and minimal heat transfer, which is ideal for delicate jewelry components. According to a 2022 industry report, the demand for laser welding technology in the jewelry sector is projected to grow by 15% annually, driven by the growing need for intricate designs and high-quality finishes.

Resistance welding machines, on the other hand, apply electrical current to create heat at the junction point of the metals being joined. This method is often favored for its speed and efficiency, making it suitable for production settings where time is a critical factor. As highlighted in a recent market analysis, about 30% of jewelers prefer resistance welding for its ability to produce consistent results across multiple pieces quickly. Lastly, TIG welding, or tungsten inert gas welding, provides versatile applications for various metal types, allowing for both intricate work and robust structural joints. Its adaptability gives it a strong foothold in the industry, accounting for approximately 25% of the jewelry welding machines used by professionals today.

Understanding these types can significantly influence the selection process for both professional jewelers and DIY enthusiasts, ensuring they choose a machine that best fits their specific needs and project requirements.

Top Jewelry Welding Machines for Professional and DIY Jewelers in 2023

Comparison of Top Brands in Jewelry Welding Machines for Professionals

When it comes to jewelry welding machines, professionals and DIY jewelers alike require reliable and efficient tools that meet the demands of intricate designs and high-quality craftsmanship. A comparative analysis of various brands reveals significant differences in technology and usability. According to a recent industry report, the global jewelry welding machine market is expected to grow at a compound annual growth rate (CAGR) of 5.4% between 2021 and 2028. This indicates an increasing reliance on advanced solutions that enhance precision and speed in jewelry production.

Key features that differentiate leading brands include laser technology, user interface, and serviceability. Laser welding machines are particularly favored for their ability to provide precise joints with minimal heat impact, which is crucial for maintaining the integrity of delicate materials. Furthermore, ergonomics and intuitive controls play a pivotal role in ensuring that both professionals and beginners can produce consistent results without extensive training. Recent surveys show that over 70% of jewelers prioritize ease of use and maintenance when selecting welding machines, showcasing the importance of machine design in the overall user experience.

In addition to performance, the availability of technical support and replacement parts is vital for maintaining productivity in a competitive market. As more jewelers adopt welding technology, brands offering comprehensive support packages are emerging as frontrunners in customer satisfaction. Data indicates that businesses with robust after-sales service see a 15% higher customer retention rate, underscoring the significance of not just the initial purchase, but also ongoing service capabilities.

Key Specifications and Performance Metrics for DIY Jewelers

When selecting a jewelry welding machine, DIY jewelers should focus on key specifications and performance metrics that align with their project needs. One critical aspect is the machine's welding power, typically measured in watts. A higher wattage allows for more robust and precise welds, essential for intricate designs and the use of various materials, including gold, silver, and platinum. Additionally, adjustable settings for power and pulse duration are vital for achieving optimal results on different thicknesses of metal.

Another important consideration is the machine’s cooling system. A reliable cooling mechanism can prevent overheating during prolonged use, ensuring the integrity of the welds and extending the machine's lifespan. A lightweight and portable design can also enhance usability, allowing jewelers to work comfortably in various settings, whether in a home studio or at a customer location.

Lastly, ease of use and maintenance features, such as automatic cleaning functions or intuitive controls, can significantly influence the overall experience for both novice and experienced jewelers.

Cost Analysis: Budget vs. Premium Jewelry Welding Machines

When considering jewelry welding machines, the cost can vary significantly between budget and premium models, impacting both professional and DIY jewelers.

Budget machines typically range from $1,000 to $3,000. These entry-level options often come with basic features, making them suitable for occasional users or hobbyists. A study by the Jewelers' Circular Keystone (JCK) industry report indicates that while budget machines are appealing due to their lower initial investment, they might lack the precision and durability required for more intricate designs or heavier usage. Consequently, users may face additional costs for repairs or replacements, reducing the overall value.

On the other hand, premium jewelry welding machines can range from $4,000 to over $10,000, depending on features like advanced welding technology, better thermal control, and enhanced user interfaces. According to a 2022 report by the International Gem Society (IGS), investing in high-quality welding equipment can lead to substantial long-term savings for jewelers, as these machines often offer greater energy efficiency and lower maintenance costs. Additionally, the quality of welds produced can significantly affect the resale value of crafted pieces, enhancing profitability. Therefore, while the upfront cost may be higher, premium machines can deliver a more reliable and professional standard of work, making them a wise investment for serious jewelers looking to expand their capabilities.

Safety Standards and Guidelines for Operating Welding Machines

Operating welding machines for jewelry requires an adherence to rigorous safety standards and guidelines to ensure the well-being of both professional and DIY jewelers. According to the Occupational Safety and Health Administration (OSHA), overexposure to welding fumes can lead to serious health issues, including respiratory problems and metal fume fever. Jewelers must employ appropriate ventilation systems, such as fume extractors or local exhaust ventilation, to minimize inhalation risks. Additionally, personal protective equipment (PPE) like welding helmets, gloves, and aprons made of flame-resistant materials are essential in safeguarding against burns and eye injuries.

The National Fire Protection Association (NFPA) also emphasizes the importance of safe practices in welding environments. Ensuring that the workspace is free of flammable materials and maintaining a clean, organized area can significantly reduce the risk of fire hazards. Regular inspections of welding equipment for damage or wear are crucial, as defective tools can lead to accidental injuries. By following established safety protocols and guidelines—such as those outlined by OSHA and NFPA—jewelers can create a safer working environment, fostering not only individual safety but also enhancing overall productivity in the jewelry-making process.

Future Trends in Jewelry Welding Technology for Professionals

As the jewelry industry continues to innovate, welding technology is evolving at an unprecedented pace, offering jewelers new tools and techniques to enhance their craft. The future of jewelry welding focuses on the integration of advanced laser techniques and automated processes that aim to improve precision and efficiency. These advancements not only streamline production but also enable the creation of intricate designs that were once challenging to achieve. Professionals are likely to adopt these technologies to remain competitive, elevating their craftsmanship to new heights.

When considering the shift towards modern welding solutions, jewelers should keep a few tips in mind. First, investing in training programs focused on new welding technologies can be extremely beneficial. This ensures a smooth transition and helps jewelers fully harness the capabilities of modern machines. Secondly, staying updated on emerging trends and techniques through workshops or industry conferences can provide insights that drive innovation in their work.

Moreover, embracing sustainable practices within welding technology will likely be a significant trend in the future. More jewelers are expected to seek eco-friendly options that minimize waste and energy consumption. By integrating these practices into their workflows, both professionals and DIY enthusiasts can contribute to a more sustainable future while enhancing the quality and appeal of their jewelry creations.

Top Jewelry Welding Machines for Professional and DIY Jewelers in 2023

| Machine Type | Welding Technology | Power Output (W) | Weight (kg) | Price Range ($) | User Rating |

|---|---|---|---|---|---|

| Laser Welder | Laser Welding | 1000 | 50 | 3000-5000 | 4.7 |

| Micro TIG Welder | TIG Welding | 200 | 25 | 1500-2500 | 4.5 |

| Spot Welder | Resistance Welding | 500 | 15 | 800-1500 | 4.2 |

| Plasma Welder | Plasma Welding | 1200 | 45 | 4000-6000 | 4.6 |

| Orbital Welder | Orbital Welding | 800 | 30 | 2000-3500 | 4.8 |

FAQS

: Key features to consider include adjustable power output, welding technology (like pulse arc or laser welding), built-in safety mechanisms, user-friendly interfaces, and portability options.

The three main types are laser welders, resistance welders, and TIG welders, each offering unique advantages for different welding applications.

Laser welding provides high precision and minimal heat transfer, making it ideal for delicate jewelry components and intricate designs.

Resistance welding applies electrical current to create heat at the junction, making it fast and efficient, which is prefered for production settings.

TIG welding is versatile and suitable for both intricate work and robust structural joints, making it a popular choice among professionals.

The industry is seeing advancements in laser techniques, automation, and sustainable practices, enabling more intricate designs and enhanced efficiency.

Jewelers should invest in training programs, stay updated on industry trends, and participate in workshops to seamlessly integrate new technologies into their work.

By adopting eco-friendly welding practices that minimize waste and energy consumption, jewelers can enhance their jewelry quality while contributing to sustainability.

Conclusion

The article "Top Jewelry Welding Machines for Professional and DIY Jewelers in 2023" explores the essential features and considerations for selecting jewelry welding machines in the current year. It provides insights into the different types of machines available, catering to both professional jewelers and DIY enthusiasts. The discussion includes key specifications and performance metrics that are crucial for effective jewelry welding, along with a thorough cost analysis comparing budget options to premium choices.

Additionally, the article emphasizes the importance of adhering to safety standards and guidelines when operating these machines. Looking ahead, it examines future trends in jewelry welding technology that could shape the industry, ensuring that jewelers remain equipped with cutting-edge tools for their craft. Overall, this resource serves as a comprehensive guide for anyone looking to invest in a jewelry welding machine, enhancing their skills and efficiency in jewelry making.

Related Posts

-

What is the Innovation Behind 100w Laser Jewelry Welder Technology

-

A Comprehensive Comparison of 500W Pulsed Laser Cleaner: Performance, Efficiency, and Cost

-

Exploring the Unique Features and Applications of Various Compact Fiber Laser Cutting Machines

-

Unlocking Creativity with Laser Cutter Machines for Innovative Designs

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

Unlock Your Creativity with a Mini Laser Cutting Machine for Impressive DIY Projects

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top