Unlocking Precision: How Jewelry Welding Machines Revolutionize Custom Jewelry Design

Table of Contents

- The Evolution of Jewelry Design: From Traditional Techniques to Modern Welding

- Enhancing Customization: The Role of Welding Machines in Unique Jewelry Production

- Precision Engineering: How Welding Technology Improves Design Accuracy

- Efficiency Boost: Time-Saving Advantages of Jewelry Welding Machines

- Sustainability in Jewelry: The Eco-Friendly Impacts of Welding Methods

- Future Trends: Innovations in Jewelry Welding and Design Possibilities

- FAQS

- Conclusion

- Related Posts

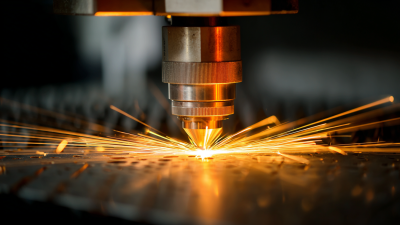

In the ever-evolving world of custom jewelry design, precision and innovation are paramount. The Jewelry Welding Machine has emerged as a game-changer, enabling artisans and designers to create intricate and bespoke pieces with unparalleled accuracy. This technological advancement is transforming the craft, allowing for intricate designs that were previously unattainable.

Maven Laser Automation Co., Ltd., a premier manufacturer of laser systems and automation solutions, has been at the forefront of this revolution since its establishment in 2008 in Shenzhen, China. By integrating advanced laser technology into jewelry production, Maven Laser not only enhances the efficiency of the manufacturing process but also elevates the quality and creativity of custom jewelry. As the demand for personalized and unique pieces continues to grow, the role of Jewelry Welding Machines in this industry becomes increasingly vital, paving the way for a new era in jewelry craftsmanship.

The Evolution of Jewelry Design: From Traditional Techniques to Modern Welding

The evolution of jewelry design has seen a remarkable transition from traditional crafting techniques to the integration of modern technology, such as jewelry welding machines. These machines have transformed the way artisans approach the creation of custom jewelry, allowing for greater precision and efficiency. Traditional methods were often labor-intensive and relied heavily on skilled hands, while modern welding techniques enable faster production times and more intricate designs without compromising quality.

As a key player in this evolution, Maven Laser Automation Co., Ltd. has been at the forefront of developing advanced laser systems that facilitate the customization of jewelry. Founded in 2008 and located in Shenzhen, China, Maven Laser specializes in professional automation solutions, catering to the growing demand for innovative jewelry design technologies. Their cutting-edge machinery empowers jewelers to explore new creative avenues, enhancing the charm and appeal of bespoke pieces.

Tips for jewelers looking to incorporate welding machines into their workflow include investing in high-quality equipment that offers versatility, such as those designed by Maven Laser. Additionally, staying updated on the latest techniques and processes can help artisans maximize their creativity while ensuring the durability of their pieces. Embracing continuous learning and experimentation can lead to stunning results in the world of custom jewelry design.

Enhancing Customization: The Role of Welding Machines in Unique Jewelry Production

The advent of welding machines has significantly enhanced customization capabilities in the jewelry industry, allowing artisans to create unique pieces that cater to individual customer preferences. According to a report by the Jewelers of America, 70% of consumers express a desire for personalized jewelry that reflects their unique identity. This shift in consumer demand has prompted jewelers to adopt advanced welding technologies, facilitating intricate designs that were previously unattainable with traditional methods.

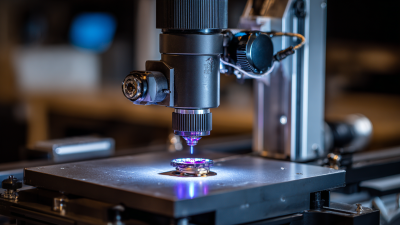

Welding machines not only improve the precision of custom jewelry production but also streamline the manufacturing process. As per a market analysis by IBISWorld, the jewelry manufacturing industry has seen an annual growth rate of 3.6% over the past five years, largely attributed to innovative technologies like laser and micro-welding machines. These advanced tools enable jewelers to execute detailed work with greater speed and accuracy, reducing production time and minimizing waste. This revolution in customization not only meets rising consumer demand for unique pieces but also allows small businesses to compete in an increasingly competitive market.

Precision Engineering: How Welding Technology Improves Design Accuracy

In the realm of custom jewelry design, precision is paramount. The advent of advanced welding technology has significantly transformed the way jewelers approach their craft. With the introduction of jewelry welding machines, the accuracy of intricate designs has reached new heights. These machines enable artisans to create seamless connections between components, ensuring that delicate pieces are both aesthetically pleasing and structurally sound. This precision engineering allows for greater creativity, as designers can experiment with complex shapes and intricate detailing without the fear of compromising integrity.

Moreover, the precision that welding technology brings to jewelry design is not just about aesthetics; it also enhances the overall durability of the pieces. Traditional soldering methods, which can sometimes introduce weaknesses at the joints, are being replaced by precise welding techniques. This results in stronger bonds that withstand the wear and tear of daily use. Consequently, jewelers can offer customers not only beautiful but also long-lasting creations. This synergy of technology and artistry is redefining custom jewelry, making it more innovative and reliable than ever before.

Efficiency Boost: Time-Saving Advantages of Jewelry Welding Machines

The advent of jewelry welding machines marks a transformative shift in custom jewelry design, offering significant time-saving advantages. These machines utilize advanced laser welding technology, which not only enhances precision but also streamlines the production process. By allowing jewelers to fuse metal parts without the need for traditional soldering, secrets to efficient design workflow are unlocked. This innovation leads to reduced turnaround times for custom pieces, enabling jewelers to meet customer demands more swiftly.

Tips for optimizing your jewelry design process with welding machines include maintaining the right temperature settings to avoid metal distortion and ensuring cleanliness in the work area to prevent contamination. Additionally, investing time in training with the machinery can maximize the benefits of this technology, helping artisans create intricate designs more reliably and with greater accuracy. Embracing these machines can lead to enhanced creativity in design as artisans spend less time on technical challenges and more time perfecting their craft.

Unlocking Precision: Efficiency Boost in Custom Jewelry Design

Sustainability in Jewelry: The Eco-Friendly Impacts of Welding Methods

The jewelry industry is experiencing a transformative shift towards sustainability, particularly through the use of advanced welding methods. Traditional manufacturing processes often result in significant waste and environmental degradation, but modern jewelry welding machines offer a more eco-friendly approach. By utilizing laser or micro-welding technologies, these machines minimize the amount of material required during the design and production stages. The precision of welding allows artisans to create intricate designs without excessive material loss, aligning with eco-conscious consumer demands.

Furthermore, the durability and precision of welding methods reduce the need for repair and replacement, promoting a longer lifespan for jewelry pieces. This not only lessens the carbon footprint associated with manufacturing new items but also supports a circular economy by encouraging consumers to invest in quality over quantity. As the trend of sustainability gains momentum, these innovative welding techniques pave the way for a greener future in custom jewelry design, demonstrating that beauty and responsibility can coexist in crafting exquisite pieces.

Future Trends: Innovations in Jewelry Welding and Design Possibilities

The world of jewelry design is undergoing a significant transformation, driven by innovations in welding technology. As jewelers increasingly adopt advanced welding machines, the precision and creativity within custom jewelry design take center stage. These machines allow for intricate designs that were previously unattainable, facilitating the seamless joining of different materials and enabling the creation of unique pieces that reflect personal styles and preferences.

Future trends in jewelry welding promise even more exciting possibilities. With the integration of AI and digital tools, designers will be able to experiment with complex geometries and revolutionary materials, enhancing the aesthetic appeal of their creations. Moreover, automation in the welding process will not only increase efficiency but also reduce production costs, making custom designs more accessible to a wider audience. As these technologies evolve, the boundaries of creativity in jewelry design will continue to expand, paving the way for a new era of artistry where bespoke jewelry becomes the norm rather than the exception.

FAQS

: Welding machines have significantly enhanced the customization capabilities in the jewelry industry, allowing artisans to create unique pieces tailored to individual customer preferences.

According to a report by the Jewelers of America, 70% of consumers express a desire for personalized jewelry that reflects their unique identity.

The shift in consumer demand for unique jewelry has prompted jewelers to adopt advanced welding technologies to facilitate intricate designs that traditional methods couldn't achieve.

Welding machines improve precision and streamline the manufacturing process, allowing for detailed work to be executed with greater speed and accuracy, thus reducing production time and waste.

Modern welding methods, such as laser and micro-welding, minimize material waste and environmental degradation, providing a more eco-friendly approach to jewelry production.

The durability and precision of welding methods reduce the need for repairs and replacements, promoting longer lifespans for jewelry pieces and minimizing the carbon footprint associated with manufacturing new items.

The precision of welding techniques allows for intricate designs with minimal material loss, aligning with the growing eco-conscious consumer demand for sustainable products.

By enabling the production of unique and high-quality pieces quickly and efficiently, welding machines help small businesses compete in an increasingly competitive market.

By encouraging consumers to invest in quality, durable pieces that last longer, advanced welding technologies support a circular economy, reducing the need for frequent production of new items.

Welding machines facilitate the creation of exquisite jewelry designs while also minimizing waste and environmental impact, demonstrating that beauty and responsibility can coexist in custom jewelry production.

Conclusion

The article "Unlocking Precision: How Jewelry Welding Machines Revolutionize Custom Jewelry Design" explores the transformative impact of jewelry welding machines on the craft of jewelry design. It discusses the evolution from traditional techniques to advanced welding technologies that enhance customization and precision. These machines enable designers to produce unique pieces with exceptional accuracy, significantly improving design intricacies while saving time. Moreover, the article highlights the eco-friendly advantages of modern welding methods, aligning with the growing demand for sustainability in the industry. As innovations continue to emerge, the future of jewelry design looks promising, with welding technology at the forefront of this creative revolution.

As a prominent manufacturer of laser systems, Maven Laser Automation Co., Ltd. emphasizes the importance of automation solutions in enhancing the capabilities of jewelry welding machines, demonstrating a commitment to innovation and quality in the jewelry market since its inception in 2008.

Related Posts

-

Ultimate Guide to Mastering the 200w Jewelry Spot Welder for Perfect Joints

-

Ultimate Guide to Choosing the Best Fiber Laser Welding Machine for Jewelry

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

7 Essential Tips for Using the Aser Cleaning Machine to Remove Paint from Wood

-

How to Maximize Efficiency with Laser Cleaner 3000w 5in1 in Industrial Applications

-

2025 China Import and Export Fair Insights on Laser Cleaning Machine Price 1500w Market Trends

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top