Unleashing the Power of Laser Cleaner Machines: The Future of Eco-Friendly Surface Restoration

Table of Contents

- Advantages of Laser Cleaning Technology over Traditional Methods in Surface Restoration

- Key Applications of Laser Cleaners in Various Industries: A Comparative Analysis

- Environmental Impact: How Laser Cleaners Reduce Harmful Emissions and Waste

- Market Growth and Trends: Statistics on the Adoption of Laser Cleaning Solutions

- Cost-Benefit Analysis: Investing in Laser Cleaners for Long-Term Savings and Efficiency

- Future Innovations: Emerging Technologies in Laser Cleaning Equipment and Applications

- FAQS

- Conclusion

- Related Posts

In recent years, the demand for sustainable and eco-friendly cleaning solutions has driven significant advancements in industrial cleaning technology, particularly with the rise of the Laser Cleaner Machine. According to a report by MarketsandMarkets, the laser cleaning market is projected to reach $1.3 billion by 2026, growing at a CAGR of 5.2%. This trend underscores the increasing recognition of laser cleaning as a viable alternative to traditional methods that often involve harsh chemicals and excessive waste. As a leading manufacturer of laser systems, Maven Laser Automation Co., Ltd. is at the forefront of this technological evolution. Founded in 2008 in Shenzhen, China, Maven Laser specializes in providing innovative automation solutions, serving industries that prioritize efficiency, safety, and environmental sustainability. This article explores how the Laser Cleaner Machine is reshaping surface restoration practices and driving the future of eco-friendly cleaning technologies.

Advantages of Laser Cleaning Technology over Traditional Methods in Surface Restoration

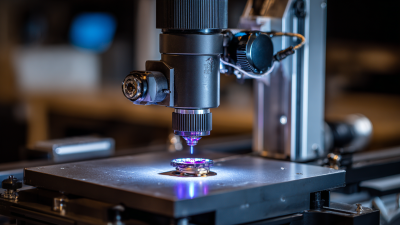

Laser cleaning technology is revolutionizing surface restoration, offering several advantages over traditional methods. Unlike conventional cleaning techniques that often involve harmful chemicals and generate considerable waste, laser cleaning utilizes focused light energy to effectively remove contaminants such as corrosion and scale. This not only minimizes environmental impact but also significantly reduces preparation time and cleanup efforts. For example, advanced laser systems are being employed in the maritime industry to restore metal surfaces with unmatched precision and efficiency, illustrating the broad applications of this innovative technology.

The global laser cleaning market is witnessing impressive growth, projected to expand from USD 0.75 billion in 2025 to USD 1.22 billion by 2033. This escalation underscores the rising demand for cleaner, greener solutions in various sectors, including aerospace and energy. Research shows that laser-induced texturing can also enhance self-cleaning properties in solar panels, further emphasizing the versatility and sustainability of laser technology. By integrating hybrid approaches, such as combining continuous and pulsed lasers, industry leaders are achieving remarkable results, particularly in the restoration of magnesium alloy substrates, showcasing the transformative potential of laser cleaning in diverse industrial applications.

Unleashing the Power of Laser Cleaner Machines: The Future of Eco-Friendly Surface Restoration - Advantages of Laser Cleaning Technology over Traditional Methods in Surface Restoration

| Advantages | Laser Cleaning | Traditional Methods |

|---|---|---|

| Environmental Impact | Minimal toxins and waste | Often uses chemicals and produces waste |

| Safety | Low risk of injury when used properly | Higher risk due to chemicals and manual labor |

| Efficiency | Fast and precise cleaning | Slower and less accurate |

| Cost-Effectiveness | Lower operational costs over time | Potentially higher long-term costs |

| Versatility | Effective on various materials | Limited to specific surfaces |

| Material Preservation | Gentle on delicate surfaces | Can damage the base material |

Key Applications of Laser Cleaners in Various Industries: A Comparative Analysis

Laser cleaner machines are rapidly emerging as a pivotal technology for eco-friendly surface restoration across multiple industries. Their ability to effectively remove contaminants while minimizing environmental impact positions them favorably against traditional methods. For instance, in the automotive sector, laser cleaners are utilized for paint stripping and rust removal, enhancing both the efficiency and sustainability of maintenance processes. Similarly, in the heritage conservation field, these machines can delicately restore intricate surfaces without causing damage to the underlying material, making them indispensable for preserving historical artifacts.

Maven Laser Automation Co., Ltd., a leader in the laser systems manufacturing industry, plays a crucial role in this technological shift. Founded in 2008 in Shenzhen, China, the company specializes in the design and production of advanced laser solutions tailored for diverse applications. By focusing on automation and precision, Maven has positioned itself at the forefront of the laser cleaning market, empowering industries to adopt cleaner practices. Their innovative approach not only enhances productivity but also aligns with global sustainability goals, showcasing the transformative power of laser technology in practical, real-world scenarios.

Environmental Impact: How Laser Cleaners Reduce Harmful Emissions and Waste

Laser cleaner machines are revolutionizing the surface restoration industry by offering an eco-friendly alternative to conventional cleaning methods. Traditional cleaning techniques often involve the use of harmful chemicals and generate a significant amount of waste, contributing to environmental degradation. In contrast, laser cleaning technology uses focused beams of light to remove contaminants such as rust, paint, and grime. This method not only minimizes the use of abrasive substances but also drastically reduces harmful emissions associated with chemical cleaners.

Furthermore, the environmental impact of laser cleaners is compelling. These machines operate with precision, targeting only the necessary areas and thus reducing the volume of waste produced during the cleaning process. Traditional methods may release volatile organic compounds (VOCs) and other pollutants into the atmosphere, whereas laser cleaning emits significantly lower levels of these harmful substances. By harnessing the power of lasers, industries can achieve high standards of cleanliness while adhering to environmental regulations and sustainability goals, marking a substantial step towards a greener future.

Market Growth and Trends: Statistics on the Adoption of Laser Cleaning Solutions

The laser cleaning market is witnessing remarkable growth, fueled by increasing awareness of eco-friendly technologies and efficient surface restoration solutions. According to industry reports, the market is anticipated to expand significantly, which aligns with the escalating trend of adopting laser cleaning solutions across various sectors. With applications spanning general manufacturing and numerous industrial needs, the laser cleaning technology market is poised for substantial development.

In a related segment, the handheld laser engraver market also demonstrates promising projections, with its value expected to soar from $15 million in 2022 to $32 million by 2030, marking a compound annual growth rate (CAGR) of 10.5% from 2024 to 2030. This upward trajectory underscores the growing inclination towards compact and versatile laser solutions in both commercial and personal applications. Additionally, as technologies evolve, so does the integration of automation in laser systems, further enhancing productivity and efficiency in various industries.

As a pioneer in this field, Maven Laser Automation Co., Ltd. has positioned itself at the forefront of these advancements. With a strong foundation in the laser market since 2008, Maven Laser continues to innovate, catering to the rising demand for sophisticated and environmentally friendly laser cleaning technologies.

Cost-Benefit Analysis: Investing in Laser Cleaners for Long-Term Savings and Efficiency

Investing in laser cleaner machines is not only an environmentally friendly choice but also a financially savvy one. A cost-benefit analysis reveals that while the initial investment may be considerable, the long-term savings and efficiency can significantly outweigh these costs. Laser cleaners reduce the need for harsh chemicals and extensive labor, which can lead to considerable savings on both materials and workforce. Additionally, their precision minimizes the risk of damage to surfaces, further protecting your investment in machinery and infrastructure.

Tips for Budgeting Your Laser Cleaner Investment:

1. Consider long-term use: Calculate potential savings on labor and materials over time to better understand the value of your investment.

2. Evaluate maintenance costs: Factor in routine maintenance and potential repairs when assessing overall costs.

3. Research financing options: Look for grants or financing programs specifically designed for eco-friendly technologies, which can help offset initial expenditures.

By implementing laser cleaning technology, businesses not only embrace a sustainable practice but can also expect improved operational efficiencies that contribute to better profit margins. In the competitive landscape of industrial cleaning, such investments can set a company apart, making cost-effectiveness and eco-friendliness not just goals, but realities.

Future Innovations: Emerging Technologies in Laser Cleaning Equipment and Applications

The future of laser cleaning technology is marked by exciting innovations that promise to reshape various industries. In 2026, we witness the growing prevalence of advanced fiber lasers, which now dominate the market due to their efficiency and eco-friendliness. Recent reports indicate a projected annual growth rate of 12% in the laser cleaning sector, driven by increasing demand for sustainable solutions in surface restoration. Notably, pioneering systems featuring pulsed laser technology are enhancing surface preparation processes, allowing for faster, safer, and more precise cleaning applications across sectors like aerospace and manufacturing.

In addition to traditional applications, emerging technologies are opening new avenues for laser cleaning. High-temperature lasers are being integrated into eco-friendly production methods, making it feasible to use these devices for energy efficiency improvements in industrial settings. Moreover, innovative approaches are enabling the cleaning of complex geometries and delicate surfaces with minimal environmental impact. As the industry evolves, major players are continuously unveiling new solutions, underscoring a commitment to sustainability and precision that will define the future of surface restoration in the coming years.

Unleashing the Power of Laser Cleaner Machines: Eco-Friendly Surface Restoration Trends

FAQS

: Laser cleaning technology offers several advantages, including the elimination of harmful chemicals, reduced waste generation, faster preparation and cleanup times, and unmatched precision in removing contaminants like corrosion and scale.

Laser cleaning significantly minimizes environmental impact by using focused light beams instead of harmful chemicals, producing lower emissions of volatile organic compounds (VOCs), and generating less waste during the cleaning process.

Laser cleaning technology is being employed in various industries, including maritime, aerospace, and energy sectors, showcasing its broad applications in surface restoration.

The global laser cleaning market is projected to expand from USD 0.75 billion in 2025 to USD 1.22 billion by 2033, indicating a rising demand for eco-friendly cleaning solutions.

Laser-induced texturing enhances the self-cleaning properties of solar panels, demonstrating the versatility of laser technology beyond surface restoration.

Increasing awareness of eco-friendly technologies and efficient surface restoration solutions are key trends driving the adoption of laser cleaning across various sectors.

The handheld laser engraver market is expected to grow from $15 million in 2022 to $32 million by 2030, reflecting a compound annual growth rate (CAGR) of 10.5%.

The integration of automation in laser systems is enhancing productivity and efficiency, contributing to the overall growth and sophistication of the laser cleaning technology market.

Maven Laser Automation Co., Ltd. is a pioneer in the laser market, established in 2008, and continues to innovate in eco-friendly laser cleaning technologies.

Conclusion

The rise of Laser Cleaner Machines signifies a transformative shift in the field of eco-friendly surface restoration. Unlike traditional cleaning methods, laser cleaning technology boasts numerous advantages, including reduced waste and harmful emissions, making it a sustainable choice for various industries. Key applications range from heritage restoration to industrial machinery maintenance, demonstrating its versatility and effectiveness.

Market trends indicate a growing adoption of laser cleaning solutions, driven by the cost-benefit advantages and efficiency they offer. With continuous innovations emerging in laser technology, such as enhanced automation and improved cleaning capabilities, businesses like Maven Laser Automation Co., Ltd. are at the forefront of this industry. By investing in Laser Cleaner Machines, companies not only achieve long-term savings but also contribute to a cleaner and greener environment.

Related Posts

-

7 Tips for Choosing the Best Pulse Laser Cleaning Machine for Rust Removal

-

Key Factors to Identify Reliable Manufacturers for the Best 3000w Handheld Laser Cleaner

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

7 Best Reasons to Invest in a Rust Cleaning Laser Machine

-

5 Reasons Why the Portable Pulse Laser Cleaner is Essential for Modern Manufacturing

-

5 Essential Tips for Optimizing Your Laser Cleaning Head Rack Performance

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top