Innovative Techniques for Using Laser Cleaner on Wood Paint Removal

Table of Contents

- Understanding the Basics of Laser Cleaning Technology for Wood Surfaces

- Preparing Your Workspace: Essential Tools and Safety Measures for Laser Cleaning

- Step-by-Step Guide to Removing Paint from Wood with a Laser Cleaner

- Tips for Achieving Optimal Results when Using a Laser Cleaner on Wood

- Common Mistakes to Avoid During the Laser Cleaning Process

- Maintaining and Caring for Your Laser Cleaner for Long-Term Use

- FAQS

- Conclusion

- Related Posts

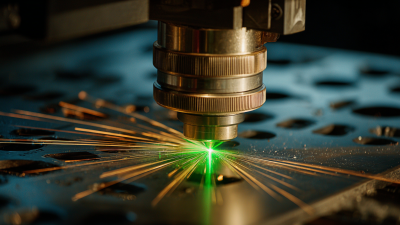

In recent years, the use of advanced technologies in the field of surface cleaning has gained significant attention, particularly in the area of "Laser Cleaner Wood Paint" removal. According to a report by Research and Markets, the laser cleaning market is projected to reach USD 2.1 billion by 2026, growing at a CAGR of 6.5%. This trend highlights the increasing demand for efficient and eco-friendly solutions in various industries, including woodworking and restoration.

As a leading manufacturer of laser systems, Maven Laser Automation Co., Ltd. has been at the forefront of this innovation since its establishment in 2008. By harnessing the power of laser technology, our systems provide precision cleaning capabilities that effectively remove wood paint without causing harm to the underlying substrate. This blog will explore innovative techniques for utilizing laser cleaners in wood paint removal, offering insights into their effectiveness and applications in the industry.

Understanding the Basics of Laser Cleaning Technology for Wood Surfaces

Laser cleaning technology has emerged as a sophisticated method for removing paint from wooden surfaces, offering a range of benefits over traditional techniques. At its core, laser cleaning works by directing a focused beam of light onto the surface, which vaporizes contaminants such as paint while preserving the integrity of the wood. This precision ensures that only unwanted layers are removed, minimizing the risk of damage to the substrate. Understanding how lasers interact with various wood types is essential for successful applications, making it crucial for users to familiarize themselves with the specific characteristics of the wood they are treating.

When using laser cleaners for wood paint removal, it’s important to follow some best practices. First, always test the laser on a small, inconspicuous area to gauge its effectiveness and ensure that the wood does not react adversely. Additionally, consider adjusting the laser’s power and speed settings according to the type of paint and wood; harder woods might require more power, while softer woods demand gentler settings. Lastly, proper safety gear is essential—always wear protective goggles and maintain a safe distance from the laser’s path to prevent accidents. These tips will help you achieve optimal results while safeguarding both the wood and yourself.

Preparing Your Workspace: Essential Tools and Safety Measures for Laser Cleaning

When preparing your workspace for laser cleaning wood paint removal, the first step is to gather essential tools to ensure efficiency and safety. A high-quality laser cleaner should be your primary tool, as its precision can effectively strip paint without damaging the wood underneath. In addition to the laser machine, having protective gear such as safety goggles, gloves, and a mask is crucial to shield yourself from both harmful dust and intense light emissions during the process. A sturdy workbench and adequate lighting will also facilitate a smoother workflow, allowing you to see the details of the wood surface clearly.

Safety measures cannot be overlooked when working with laser technology. Ensure that your workspace is well-ventilated to dissipate any fumes generated during paint removal, as these can be hazardous. It's also advisable to establish a safe distance from flammable materials and to have a fire extinguisher readily available. Before starting the operation, familiarize yourself with the laser equipment's safety features and emergency shut-off switches. Taking these precautions will not only safeguard your health but also optimize the efficiency of your laser cleaning project.

Wood Paint Removal Effectiveness of Laser Cleaning Techniques

Step-by-Step Guide to Removing Paint from Wood with a Laser Cleaner

When it comes to removing paint from wood surfaces, laser cleaning has emerged as a revolutionary technique that offers a precise and eco-friendly alternative to traditional methods. In a step-by-step guide, one would begin by preparing the workspace: ensure proper ventilation, protect surrounding areas, and wear safety gear. Next, select an appropriate laser cleaner, typically operating between 1064 nm and 532 nm wavelengths, to effectively target and vaporize the paint without damaging the underlying wood. Research indicates that laser cleaning can reduce harmful emissions by up to 90% compared to chemical solvents, making it an environmentally sustainable choice.

The application process involves adjusting the laser’s power and speed settings based on the paint's thickness and the wood type. Studies have shown that a power level of 30-100 watts is effective for most residential projects, while an optimal feed rate of around 50 mm/s can ensure thorough paint removal while preserving the wood's integrity. Once the laser is operational, it should be guided steadily across the painted surface, allowing the beam to interact with the paint layer efficiently. Ultimately, this method not only enhances the aesthetic quality of the wood but also helps maintain its structural integrity, positioning laser cleaning as a preferred option in restoration projects.

Tips for Achieving Optimal Results when Using a Laser Cleaner on Wood

When using a laser cleaner for wood paint removal, achieving optimal results requires careful attention to several key factors. First, ensure that you select the appropriate laser power settings based on the type and thickness of the paint. A higher power may be necessary for thicker or more stubborn layers, while lower power settings can effectively handle lighter coatings without damaging the wood underneath.

Another essential tip is to maintain a consistent distance between the laser head and the wood surface. This distance can greatly affect the laser's effectiveness; too close might lead to burn marks, while too far can result in inadequate paint removal. Always test a small, inconspicuous area first to fine-tune your settings before tackling larger sections.

Lastly, consider the type of wood you are working with. Softer woods such as pine may require more delicate handling compared to hardwoods like oak or walnut. Adjusting the speed of the laser cleaner can help mitigate the risk of scorching or warping the wood while ensuring complete paint removal. Evaluating these factors will help you achieve impressive results and extend the life of your wooden surfaces.

Common Mistakes to Avoid During the Laser Cleaning Process

When utilizing a laser cleaner for wood paint removal, understanding common mistakes is crucial for achieving optimal results. One frequent error is failing to properly assess the type of paint and wood to be cleaned. Different materials react differently to laser treatment; for example, softer woods may scorch more easily than hardwoods. Conducting a small test area can help gauge how the wood and paint interact with the laser, preventing damage and ensuring the best outcome.

Another mistake often made during the laser cleaning process is neglecting safety precautions. Laser cleaners emit powerful beams that can be hazardous. It’s essential to use appropriate personal protective equipment (PPE), including goggles designed for the specific wavelength of the laser being used, to protect both the eyes and skin. Additionally, ensuring proper ventilation is key to dispersing any harmful fumes generated during paint removal. Taking these precautions not only protects the user but also guarantees a smoother and more efficient cleaning process.

Maintaining and Caring for Your Laser Cleaner for Long-Term Use

When it comes to utilizing laser cleaners for wood paint removal, the longevity and performance of the equipment heavily rely on proper maintenance and care.

Regular upkeep can significantly extend the lifespan of your laser cleaner, ensuring it operates at optimal efficiency.

According to industry reports, consistent maintenance can decrease equipment failure rates by up to 30%, making it crucial for users to implement a regular cleaning schedule and inspect components such as lenses and nozzles for wear.

In addition, considering the increasing popularity of laser technologies across various sectors, including skincare and manufacturing, utilizing best practices for care can keep your laser cleaner in top shape.

Users should ensure that the equipment is stored in a dust-free environment and that any used filters are replaced according to manufacturer recommendations.

Proper handling techniques can prevent scratches and damage to sensitive parts, which can result in costly repairs or replacements. With lasers increasingly integrated into everyday applications—from beauty treatments to point-of-care pharmaceutical production—understanding and practicing maintenance protocols is essential to maximizing your investment in laser technology.

FAQS

: Laser cleaning technology involves directing a focused beam of light onto wooden surfaces to vaporize contaminants like paint while preserving the wood's integrity. This precision minimizes the risk of damage to the substrate.

Testing the laser on a small, inconspicuous area is crucial to gauge its effectiveness and ensure that the wood does not react adversely to the laser cleaning process.

Adjust the laser's power and speed settings based on the wood type; harder woods typically require higher power, while softer woods need gentler settings to avoid damage.

It is essential to wear protective goggles, gloves, and a mask to shield yourself from harmful dust and intense light emissions during the laser cleaning process.

Prepare your workspace by gathering essential tools including a high-quality laser cleaner, ensuring good ventilation, maintaining a safe distance from flammable materials, and having a fire extinguisher readily available.

Common mistakes include failing to assess the type of paint and wood and neglecting safety precautions. Conducting a test area and using appropriate personal protective equipment (PPE) can prevent damage and protect the user.

Ensure adequate ventilation, establish a safe distance from flammable materials, familiarize yourself with safety features of the laser equipment, and have an emergency shut-off switch accessible.

Yes, different paints react differently to laser treatment, and it's important to understand these interactions to avoid damaging the wood and achieve the best results.

Ensure your workspace is well-ventilated to dissipate any harmful fumes generated during the paint removal process.

Conclusion

In this blog, we delve into the innovative techniques of using laser cleaners for efficient wood paint removal, emphasizing the advantages of laser cleaning technology. We start by covering the basics of laser cleaning, preparing your workspace with essential tools and safety measures. A comprehensive step-by-step guide will walk you through the process of removing paint from wood using a laser cleaner, while tips for optimal results and common mistakes to avoid ensure a seamless experience.

Maven Laser Automation Co., Ltd., a leading manufacturer based in Shenzhen, China, has been at the forefront of laser systems since 2008. Our expertise in laser technology enhances your wood paint removal projects, allowing for precise and effective cleaning. With proper maintenance and care, a laser cleaner can provide long-term benefits and superior performance for all your wood restoration needs.

Related Posts

-

Unmatched Quality in Laser Cleaning for Wood Trim from China's Leading Manufacturer

-

Revolutionary Applications of the 200W Laser Cleaner for Wood Restoration and Maintenance

-

Unmatched Manufacturing Excellence in China Featuring the Best Laser Cleaning Head With Advanced Operating Modes

-

Revolutionizing Manufacturing: The Future of Robotic Arm Welding and Its Impact on Industry Growth

-

What Makes Best High Power Laser Welding the Ultimate Choice for Global Buyers

-

Discover High Quality Fiber Laser Marking Machine Parts from China for Your Global Business Needs

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top