What is a Laser Cleaning Head With Beam Adjustment and How Does It Work

Table of Contents

- Understanding the Basics of Laser Cleaning Heads and Beam Adjustment

- Common Issues Encountered with Laser Cleaning Heads

- How Beam Adjustment Enhances Laser Cleaning Efficiency

- Troubleshooting Techniques for Laser Cleaning Problems

- The Impact of Poor Beam Alignment on Cleaning Results

- FAQS

- Conclusion

- Related Posts

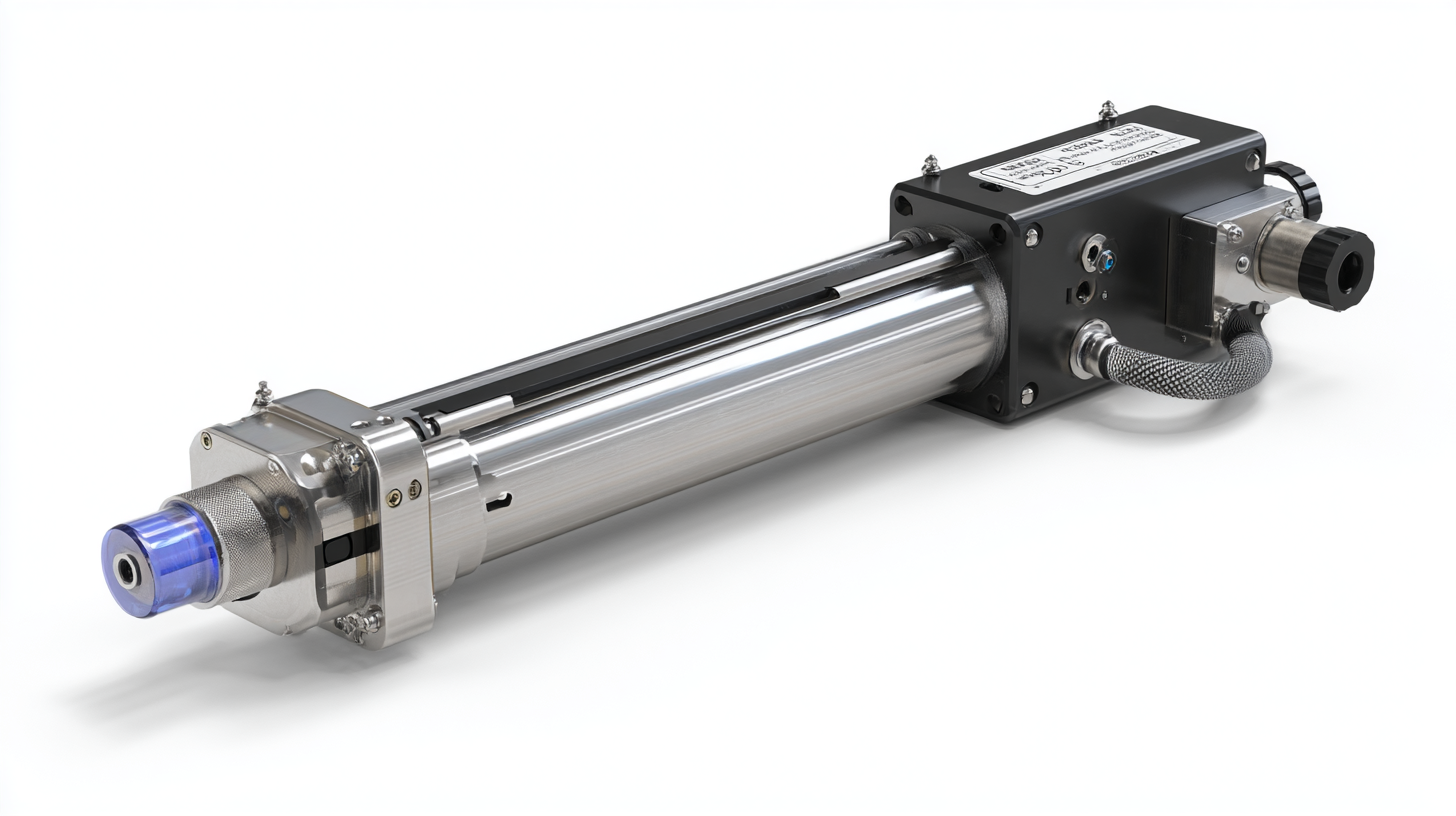

In recent years, the demand for efficient and eco-friendly cleaning solutions has surged in various industrial sectors, making innovative technologies like the Laser Cleaning Head With Beam Adjustment increasingly relevant. This advanced equipment not only offers precision in cleaning applications but also enhances operational efficiency by allowing users to customize the laser beam according to the specific requirements of different surfaces and contaminants. Maven Laser Automation Co., Ltd., a pioneer in the laser systems industry based in Shenzhen, China, has been at the forefront of this technological advancement since its establishment in 2008. With a commitment to delivering professional automation solutions and expert designs, Maven Laser continues to define the future of laser cleaning technologies, addressing common problems faced by industries while promoting sustainable practices. In this blog, we will explore the capabilities of the Laser Cleaning Head With Beam Adjustment and its benefits in solving various cleaning challenges.

Understanding the Basics of Laser Cleaning Heads and Beam Adjustment

Laser cleaning heads with beam adjustment are increasingly recognized for their effectiveness in precision cleaning applications. At their core, these devices utilize concentrated laser beams to remove contaminants from various surfaces. The ability to adjust the beam allows operators to fine-tune parameters such as intensity and focus, which is crucial for treating different materials without causing damage. This level of control ensures that the cleaning process can be optimized for specific tasks, much like in laser cutting where precise beam parameters and gas flow dynamics are essential for achieving burr-free results.

Understanding the basics of laser cleaning heads involves recognizing their operational mechanics and applications. The beam adjustment feature is not just a technical specification but a vital component that affects the outcome of the cleaning process. By manipulating the beam shape and size, users can efficiently address stubborn rust, paint, or residues on diverse surfaces. This versatility offers significant advantages over traditional cleaning methods, providing a cleaner finish and minimizing surface wear, thereby enhancing the lifespan of the treated materials. As industries continue to adopt more innovative and efficient cleaning solutions, laser cleaning technology is poised to play a key role.

Common Issues Encountered with Laser Cleaning Heads

Laser cleaning heads with beam adjustment have gained traction in various industries for their efficiency in removing contaminants from surfaces. However, while these advanced tools provide significant benefits, users often encounter several common issues that can hinder optimal performance.

One prevalent problem is inconsistent beam quality, which can lead to uneven cleaning results. According to a recent industry report from the International Journal of Laser Applications, up to 30% of users experience difficulties with beam divergence, causing inconsistent laser power distribution. This inconsistency can result in surface damage or inadequate cleaning, ultimately affecting productivity and increasing costs.

Another challenge is the maintenance of laser optics, which can be affected by contaminants and wear over time. A survey conducted by the Laser Institute of America highlighted that nearly 40% of users reported decreased efficacy due to unclean optics, necessitating frequent servicing. This not only impacts cleaning efficiency but can also lead to higher operational expenses, emphasizing the importance of regular maintenance and calibration to ensure optimal performance of laser cleaning heads.

What is a Laser Cleaning Head With Beam Adjustment and How Does It Work - Common Issues Encountered with Laser Cleaning Heads

| Feature | Description | Common Issues | Solution |

|---|---|---|---|

| Beam Adjustment | Allows users to modify the shape and intensity of the laser beam for different cleaning applications. | Inaccurate beam focus can lead to insufficient cleaning results. | Regularly calibrate the beam adjustment settings and perform test cleaning. |

| Power Control | Adjusts the power of the laser output based on the material being cleaned. | Overheating or damage to delicate materials. | Set power levels appropriately according to material specifications. |

| Nozzle Design | Designed to optimize the delivery of the laser beam to the surface. | Clogging of the nozzle can reduce efficiency. | Regularly clean the nozzle and check for debris. |

| Cooling System | Keeps the laser head at optimal operating temperatures. | Overheating can cause malfunction. | Ensure proper ventilation and check coolant levels. |

| Safety Features | Includes protective measures to avoid accidents during operation. | Failure of safety mechanisms can lead to laser exposure risks. | Regularly inspect and maintain safety devices. |

How Beam Adjustment Enhances Laser Cleaning Efficiency

Laser cleaning technology has become increasingly important in various industries, particularly in welding, where demands for enhanced productivity, efficiency, and quality are ever-present. A key innovation in this field is the beam adjustment feature in laser cleaning heads. This technology allows operators to fine-tune the laser beam parameters, enabling more precise and efficient cleaning processes. By adjusting the beam diameter and focus, operators can target specific contaminants and optimize the energy delivered to the surface, resulting in faster cleaning times and minimized material damage.

The effectiveness of beam adjustment cannot be overstated; it directly enhances the overall laser cleaning efficiency. With the ability to control the intensity and distribution of the laser beam, users can tackle a wider variety of surfaces and contaminants effectively. This capability not only boosts cleaning effectiveness but also reduces operational costs and downtime, making laser cleaning a more attractive option for industries facing stringent cleaning requirements. As the laser cleaning system market continues to grow, innovations like beam adjustment will play a crucial role in meeting these challenges while driving productivity forward.

Laser Cleaning Efficiency with Beam Adjustment

This chart illustrates the enhanced efficiency of laser cleaning when beam adjustment is utilized. The standard laser cleaning operation shows an efficiency of 70%, whereas with beam adjustment, the efficiency improves to 90%. This indicates a significant improvement in the effectiveness of the laser cleaning process.

Troubleshooting Techniques for Laser Cleaning Problems

When utilizing laser cleaning technology, operators may occasionally encounter issues that hinder optimal performance. Common problems include inconsistent cleaning rates, surface damage, and ineffective contaminant removal. According to a report by the International Journal of Advanced Manufacturing Technology, nearly 30% of laser cleaning applications face challenges related to beam adjustment and focus, emphasizing the need for proper troubleshooting techniques in these scenarios.

One effective troubleshooting method involves meticulously checking the beam's focus and alignment. Misalignment can lead to inadequate energy delivery, resulting in poor cleaning performance. Operators should confirm that all optical components are clean and properly positioned, as even minor obstructions can drastically alter the effectiveness of the cleaning process. Furthermore, adjusting the cleaning speed and power settings based on specific materials—such as metal, plastic, or glass—can enhance effectiveness and prevent material degradation. According to a study by the Society of Manufacturing Engineers, optimizing these parameters can improve cleaning efficiency by up to 50%, underscoring the importance of a systematic approach to device management.

The Impact of Poor Beam Alignment on Cleaning Results

Proper beam alignment is crucial in laser cleaning applications. When the laser beam is not properly aligned, it can lead to uneven cleaning results and can even damage the substrate being cleaned. This misalignment can cause inconsistencies in the energy distribution, leading to areas that are either over-cleaned or under-cleaned. Achieving the right alignment ensures that the beam effectively removes contaminants without compromising the underlying material.

To improve beam alignment, it is important to regularly check and calibrate your laser cleaning equipment. This can include adjusting mirrors and lenses to ensure that the beam hits the target precisely. Additionally, conducting preliminary tests on a small area can provide valuable insights into how the laser interacts with the substrate, allowing for adjustments before proceeding with a full cleaning operation.

Another tip is to consider the distance between the cleaning head and the surface. The focal point of the beam can shift with distance, affecting cleaning performance. Maintaining an optimal distance can help in achieving better results and avoiding any potential damage. By focusing on these aspects, users can enhance the efficiency and effectiveness of their laser cleaning processes.

FAQS

: Laser cleaning heads with beam adjustment are used to remove contaminants from various surfaces through concentrated laser beams, allowing for precise cleaning applications.

Beam adjustment is important because it allows operators to fine-tune parameters like intensity and focus, which is crucial for effectively treating different materials without causing damage.

Users commonly face issues such as inconsistent beam quality, which can lead to uneven cleaning results and potential surface damage, as well as the maintenance of laser optics affected by contaminants.

Inconsistent beam quality can cause uneven power distribution, leading to inadequate cleaning and potentially damaging surfaces, which ultimately affects productivity and increases costs.

Regular maintenance and calibration of the laser optics are crucial, as nearly 40% of users report decreased efficacy due to unclean optics, impacting cleaning efficiency and operational expenses.

Effective troubleshooting techniques include checking beam focus and alignment, ensuring optical components are clean, and adjusting cleaning speed and power settings based on the material being cleaned.

Misalignment can lead to inadequate energy delivery, resulting in poor cleaning performance, so proper alignment is critical for optimal results.

Laser cleaning technology can efficiently clean various materials, including metal, plastic, and glass, with adjustments made to optimize cleaning effectiveness for each type.

Nearly 30% of laser cleaning applications encounter challenges related to beam adjustment and focus, highlighting the need for proper troubleshooting.

Optimizing cleaning speed and power settings based on specific materials can enhance cleaning efficiency by up to 50%, demonstrating the importance of systematic device management.

Conclusion

The blog titled "What is a Laser Cleaning Head With Beam Adjustment and How Does It Work" provides an in-depth exploration of laser cleaning technologies, focusing on the functionality and advantages of laser cleaning heads equipped with beam adjustment capabilities. It begins with a foundational understanding of how these systems operate and highlights common issues that users may face, such as misalignment and inefficient cleaning results.

Moreover, the importance of beam adjustment in enhancing cleaning efficiency is emphasized, illustrating how proper alignment can significantly improve outcomes. The blog also includes troubleshooting techniques for addressing typical problems encountered with laser cleaning systems, and discusses the negative impact of poor beam alignment on cleaning effectiveness. Overall, this resource serves as a valuable guide for users seeking to optimize their laser cleaning processes and ensure the best performance from their equipment. Maven Laser Automation Co., Ltd., a leading manufacturer in this field, offers cutting-edge solutions to support these advancements in laser technology.

Related Posts

-

Unmatched Quality in Laser Cleaning for Wood Trim from China's Leading Manufacturer

-

Unmatched Manufacturing Excellence in China Featuring the Best Laser Cleaning Head With Advanced Operating Modes

-

Innovative Techniques for Using Laser Cleaner on Wood Paint Removal

-

How to Select Top-Quality Manufacturers for the Best Laser Cutter Machines Globally

-

Revolutionizing Manufacturing: The Future of Robotic Arm Welding and Its Impact on Industry Growth

-

Mastering Efficiency: Innovative Approaches to Optimize Your Best Laser Welding Machine Operations

Blog Tags:

Olivia

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top