How to Use a Laser Machine for Effective Rust Removal Techniques

Table of Contents

- Understanding Laser Technology for Rust Removal: Principles and Advantages

- Types of Laser Machines: Choosing the Right One for Your Rust Removal Needs

- Safety Protocols When Using Laser Machines for Rust Removal

- Effective Techniques: Optimizing Laser Settings for Different Rust Situations

- Comparative Analysis: Laser Rust Removal vs. Traditional Methods

- Case Studies: Successful Applications of Laser Technology in Rust Removal Industries

- FAQS

- Conclusion

- Related Posts

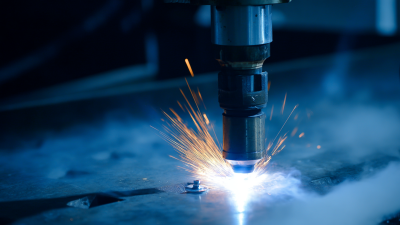

In the industrial world, maintaining the integrity of machinery and structures is paramount, especially when faced with challenges such as rust. Rust not only compromises aesthetics but can also lead to significant operational inefficiencies and safety hazards. According to a report by MarketsandMarkets, the global metal cleaning market is projected to reach $2.14 billion by 2026, highlighting the increasing demand for efficient rust removal techniques. One of the most effective methods to combat rust is the use of a Laser Machine To Clean Rust, which provides a precision-focused solution that minimizes material removal while maximizing cleaning efficacy.

In the industrial world, maintaining the integrity of machinery and structures is paramount, especially when faced with challenges such as rust. Rust not only compromises aesthetics but can also lead to significant operational inefficiencies and safety hazards. According to a report by MarketsandMarkets, the global metal cleaning market is projected to reach $2.14 billion by 2026, highlighting the increasing demand for efficient rust removal techniques. One of the most effective methods to combat rust is the use of a Laser Machine To Clean Rust, which provides a precision-focused solution that minimizes material removal while maximizing cleaning efficacy.

As a leading manufacturer of laser systems, Maven Laser Automation Co., Ltd. has been at the forefront of this technology since 2008, delivering innovative automation solutions that cater to the growing needs of various industries. By leveraging state-of-the-art laser systems, businesses can significantly enhance their rust removal practices, ensuring longevity and operational efficiency in their machinery.

Understanding Laser Technology for Rust Removal: Principles and Advantages

Laser technology has emerged as a cutting-edge solution for rust removal, offering a variety of advantages over traditional methods. The fundamental principle behind laser rust removal lies in the focused energy of the laser beam, which effectively targets and vaporizes rust particles without damaging the underlying metal surface. This precision makes lasers particularly beneficial for intricate and delicate components where conventional techniques may risk causing further damage.

One of the primary advantages of using lasers for rust removal is the minimal environmental impact. Unlike chemical treatments that can produce hazardous waste, laser systems operate without the need for abrasive materials or harmful chemicals. Furthermore, laser cleaning can significantly reduce labor costs and time efficiency, as the process is often quicker and requires less manual intervention. By enhancing the speed and safety of rust removal, laser technology not only extends the life of metal surfaces but also contributes to more sustainable industrial practices.

How to Use a Laser Machine for Effective Rust Removal Techniques - Understanding Laser Technology for Rust Removal: Principles and Advantages

| Technique | Advantages | Disadvantages | Application Areas | Cost Estimate |

|---|---|---|---|---|

| Laser Rust Removal | Highly efficient, precise removal of rust; minimal impact on substrate material | Initial setup cost can be high; requires trained personnel | Automotive parts, industrial machinery, marine applications | $100 - $300 per hour |

| Chemical Rust Removal | Cost-effective for large areas; can be done by unskilled labor | Potentially harmful chemicals; slower process | Construction sites, restoration projects | $20 - $50 per gallon of solution |

| Sandblasting | Effective for heavy rust; can cover large surfaces quickly | Can damage underlying material; produces dust | Heavy machinery, outdoor structures | $75 - $150 per hour |

| Power Washing with Rust Inhibitor | Accessible method; prevents future rusting | Less effective on deep rust; requires chemical application | Residential areas, vehicles, machinery | $50 - $100 per session |

Types of Laser Machines: Choosing the Right One for Your Rust Removal Needs

When it comes to choosing the right laser machine for rust removal, it's essential to understand the different types available on the market. Generally, laser machines can be categorized into fiber lasers, CO2 lasers, and UV lasers. Fiber lasers, known for their efficiency and precision, are particularly effective for metal surfaces. According to a report by the International Laser Display Association, fiber lasers can remove rust with minimal thermal impact, making them ideal for delicate applications.

CO2 lasers, on the other hand, are suitable for thicker materials and provide a balance between power and cost-effectiveness. While they can be less efficient for metals compared to fiber lasers, they excel in more broad-spectrum applications, including treatment of various substrates. UV lasers, with their shorter wavelength, are used for specific applications requiring high precision and low heat impact, which is particularly useful for sensitive electronic components.

Tips: When selecting a laser machine, consider the material and thickness of the rusted surface. Evaluate the operational costs associated with each machine, as this can significantly affect the overall efficiency of your rust removal process. Finally, ensure that you have access to proper training and support, as effective usage is crucial for achieving superior results in rust removal.

Safety Protocols When Using Laser Machines for Rust Removal

When utilizing laser machines for rust removal, adhering to strict safety protocols is crucial to ensure both operator safety and the effective operation of the equipment. First and foremost, it is essential to wear appropriate personal protective equipment (PPE) including laser safety goggles, gloves, and long sleeves to shield against potential hazards. The powerful beams of a laser not only produce intense light but can also generate heat and sparks, making it imperative to create a controlled work environment free of flammable materials.

In addition to personal protective measures, establishing clear operational guidelines can minimize risks. Operators should receive comprehensive training on the specific laser equipment being used, including understanding the machine's settings and capabilities. Furthermore, maintaining a safe distance from the laser beam and ensuring that bystanders are at a safe distance is vital. Proper ventilation must also be in place to manage any fumes produced during the rust removal process. By following these protocols, operators can enhance safety while achieving effective rust removal with laser technology.

Effective Techniques: Optimizing Laser Settings for Different Rust Situations

When using a laser machine for rust removal, optimizing your laser settings is crucial to achieve the best results for various surfaces and rust conditions. Different types of rust and materials require specific laser power, speed, and frequency adjustments. For heavier rust deposits, a slower speed and higher power setting are recommended, allowing the laser to penetrate deeper and effectively vaporize the rust. Conversely, if you're dealing with lighter rust or sensitive materials, a faster speed with a lower power setting can minimize the risk of damage while still providing a thorough clean.

**Tips:** Always start with a test patch to assess how the laser interacts with the material. This can help you fine-tune the settings before committing to larger areas. Additionally, consider the type of laser lens being used; a focused lens can provide more precision, while a wider lens might be better for larger surfaces.

Maintaining a steady hand and the appropriate distance from the surface can also significantly impact the outcome. Keeping the laser tip at the recommended distance from the surface ensures an even application of power and helps improve the efficiency of rust removal. Regularly monitor your progress to make real-time adjustments based on the performance of the machine.

Laser Settings for Effective Rust Removal Techniques

Comparative Analysis: Laser Rust Removal vs. Traditional Methods

Laser rust removal has garnered attention in recent years, particularly when compared to traditional methods like sandblasting or chemical treatments. According to a report by the International Journal of Advanced Manufacturing Technology, laser technology can remove rust more efficiently while minimizing surface damage. Traditional methods often involve abrasive materials that can lead to substrate weakening, especially in delicate components. The laser method, on the other hand, can effectively target rust without affecting the integrity of the underlying material, making it ideal for precision engineering applications.

Moreover, studies indicate that laser rust removal can reduce cleaning times by up to 50%, significantly enhancing productivity in industrial settings. A comparative analysis presented in the Journal of Industrial Engineering highlights that while initial investment in laser technology may be higher, the long-term cost savings in labor and material waste make it a more economically viable solution. With laser methods producing minimal secondary waste, they also present a more environmentally friendly alternative compared to conventional techniques that often rely on harsh chemicals and produce substantial waste. As industries seek sustainable practices, laser rust removal stands out as a cutting-edge solution poised to revolutionize rust management.

Case Studies: Successful Applications of Laser Technology in Rust Removal Industries

Laser technology has revolutionized the rust removal industry, showcasing its efficacy through various successful applications. One notable case study involved the restoration of historical machinery, where laser systems were employed to safely and efficiently strip away rust without damaging intricate components. This method not only preserved the integrity of the machinery but also significantly reduced the labor and time involved in traditional rust removal processes.

Maven Laser Automation Co., Ltd., a pioneer in laser systems, exemplifies these advancements. Since its establishment in 2008, the company has been at the forefront of laser technology innovations in rust removal. Their expertise in designing, producing, and selling laser solutions has enabled industries to achieve cleaner surfaces and extend the lifespan of their equipment.

Tips for Effective Laser Rust Removal:

- Ensure the correct selection of laser type and settings to match the substrate material, as different metals react uniquely.

- Regular maintenance of the laser machine enhances performance and minimizes downtime, ensuring optimal results.

- Always conduct preliminary tests on a sample surface to determine the most effective technique before starting on larger projects.

FAQS

: The main types of laser machines used for rust removal are fiber lasers, CO2 lasers, and UV lasers. Fiber lasers are efficient for metal surfaces, CO2 lasers are suitable for thicker materials and various substrates, while UV lasers offer high precision for delicate applications.

Laser rust removal is more efficient, reduces cleaning times by up to 50%, and minimizes surface damage compared to traditional methods like sandblasting or chemical treatments, which can weaken underlying materials.

The benefits include minimal secondary waste, reduced labor and material costs in the long run, and an environmentally friendly approach compared to conventional techniques that utilize harsh chemicals.

Consider the material and thickness of the rusted surface, evaluate the operational costs, and ensure access to proper training and support for effective usage.

Yes, laser technology has been successfully applied in the restoration of historical machinery, allowing for safe rust removal without damaging intricate components.

Regular maintenance is crucial as it enhances performance, minimizes downtime, and ensures optimal results during the rust removal process.

Yes, conducting preliminary tests on a sample surface is recommended to determine the most effective technique and settings for the specific rust removal project.

While fiber lasers are particularly effective for metal surfaces, their effectiveness on non-metal surfaces may vary, and other laser types may be more suitable for those applications.

While the initial investment in laser technology may be higher, the long-term savings in labor and material waste make it a more economically viable solution over time.

Proper training in operating the specific laser machine, understanding its settings, and learning best practices for rust removal is highly recommended for optimal results.

Conclusion

Maven Laser Automation Co., Ltd. highlights the effective use of laser machines to clean rust, showcasing the superior advantages of laser technology in rust removal processes. By understanding the principles of laser technology, users can select the right type of laser machine tailored to their specific rust removal needs. Safety protocols are of utmost importance, ensuring that operators can use these machines without risk.

Optimizing laser settings for different rust situations allows for efficient and effective rust elimination compared to traditional methods. Case studies demonstrate the successful application of laser technology across various industries, further confirming its effectiveness. With a commitment to providing high-quality laser systems, Maven Laser Automation Co., Ltd. stands as a leader in the market, making laser machines an optimal choice for cleaning rust.

Related Posts

-

Unmatched Manufacturing Excellence in China Featuring the Best Laser Cleaning Head With Advanced Operating Modes

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

-

5 Essential Tips for Using Pulse Laser Cleaning Machine for Rust Removal

-

5 Essential Tips for Maximizing Efficiency with Your Rust Cleaning Laser Machine

-

What is the Efficiency of 200w Pulse Laser Cleaning Machine for Wood Applications

-

Excellence in Manufacturing with the Best Mini Fiber Laser Machine from China to the World

Blog Tags:

Olivia

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top