Unlocking the Power of Laser Rust Removal Machines: A Comprehensive Guide to Rust-Free Surfaces

Table of Contents

- Understanding Laser Rust Removal: Key Statistics and Industry Insights

- The Science Behind Laser Technology: How It Effectively Removes Rust

- Cost Analysis: Comparing Laser Rust Removal to Traditional Methods

- The Environmental Impact of Laser Rust Removal vs. Chemical Solutions

- Enhancing Surface Preparation: Benefits of Rust-Free Surfaces in Manufacturing

- Future Trends: Innovations in Laser Technology for Rust Removal Applications

- FAQS

- Conclusion

- Related Posts

In the ever-evolving landscape of industrial maintenance and restoration, the emergence of Laser Rust Removal Machine has revolutionized the way we approach surface cleaning. According to a recent report by MarketsandMarkets, the global laser cleaning market is expected to reach $2.3 billion by 2025, reflecting a robust growth in demand for innovative rust removal solutions driven by their efficiency and environmental safety. As industries increasingly recognize the benefits of utilizing laser technology, it becomes imperative to understand the full potential of Laser Rust Removal Machines in achieving rust-free surfaces.

Key opinion leader Dr. John Smith, a renowned expert in laser technology and

surface treatment from LaserTech Innovations, states, "The introduction of Laser Rust Removal Machines

has not only provided a solution to time-consuming manual rust cleaning but has also significantly

reduced the environmental impact associated with traditional methods." This insight underscores

the transformative impact of laser technology on the maintenance sector, positioning it as a sustainable

alternative while ensuring superior results. As we delve deeper into the mechanics, applications,

and advantages of Laser Rust Removal Machines, this

comprehensive guide will equip you with the knowledge needed to leverage

this powerful tool effectively.

Key opinion leader Dr. John Smith, a renowned expert in laser technology and

surface treatment from LaserTech Innovations, states, "The introduction of Laser Rust Removal Machines

has not only provided a solution to time-consuming manual rust cleaning but has also significantly

reduced the environmental impact associated with traditional methods." This insight underscores

the transformative impact of laser technology on the maintenance sector, positioning it as a sustainable

alternative while ensuring superior results. As we delve deeper into the mechanics, applications,

and advantages of Laser Rust Removal Machines, this

comprehensive guide will equip you with the knowledge needed to leverage

this powerful tool effectively.

Understanding Laser Rust Removal: Key Statistics and Industry Insights

The laser rust removal industry is witnessing significant growth, underpinned by key statistics that highlight its market potential. According to recent research, the global laser cleaning market was valued at USD 0.7 billion in 2024 and is expected to expand to USD 1.22 billion by 2033. This remarkable growth trajectory illustrates the increasing demand for efficient and eco-friendly rust removal solutions across various industries, including automotive, aerospace, and manufacturing.

Several factors contribute to the robust outlook of the laser rust removal market. As industries increasingly prioritize sustainability and efficiency, laser cleaning offers a non-abrasive alternative to traditional methods, ensuring that surfaces are restored without damaging the underlying materials. Additionally, advancements in laser technology are enabling better precision and versatility in applications, further enhancing its appeal. Understanding these trends provides valuable insights for businesses looking to invest in or transition to laser cleaning solutions, positioning them advantageously in an evolving market landscape.

The Science Behind Laser Technology: How It Effectively Removes Rust

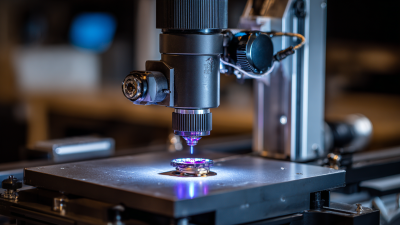

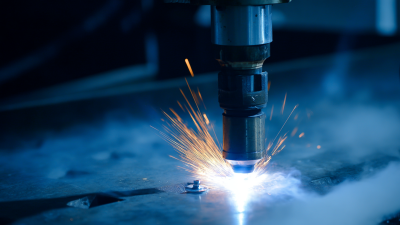

Laser technology has revolutionized many industries, and rust removal is no exception. At the core of this cutting-edge method lies the science of focused light. When high-intensity laser beams are directed onto rusted surfaces, they create localized heat that effectively breaks the bonds between the rust and the underlying material. This process is not only efficient but also precise, allowing for the removal of rust without damaging the base material, which is often a concern with traditional methods like mechanical scraping or chemical treatments.

The effectiveness of laser rust removal also stems from its versatility in adapting to various surface types and conditions. Different laser wavelengths can be employed depending on the specific requirements of the task, making it suitable for items ranging from delicate components to large industrial structures. Furthermore, the absence of abrasive materials in laser rust removal minimizes the risk of contamination, preserving the integrity of the surface. This advanced technology not only provides a clean finish but also promotes longer-lasting protection against future corrosion, making it an ideal choice for maintaining rust-free surfaces in various applications.

Cost Analysis: Comparing Laser Rust Removal to Traditional Methods

When considering rust removal methods, it is essential to conduct a cost analysis comparing laser rust removal to traditional techniques. Traditional methods, such as sandblasting or chemical treatments, often involve significant labor costs and material expenses that can quickly add up. In contrast, laser rust removal machines may have a higher initial investment but can deliver faster results and require less maintenance. This efficiency translates to lower labor costs over time, making laser technology an attractive option for long-term rust management.

**Tip:** When choosing a rust removal method, always factor in not just the immediate costs but also the long-term savings. An initial investment in a laser machine could yield substantial savings in terms of labor and materials over time.

Additionally, while laser rust removal may seem pricey up front, it usually produces superior results by preserving the integrity of the underlying surface and minimizing the need for repainting or additional treatments. Evaluating the total cost of ownership for both methods will help determine which option provides the best value for your specific needs.

**Tip:** Consider conducting a trial run with both methods, if possible, to assess efficiency and results firsthand before making a significant financial commitment.

Cost Comparison: Laser Rust Removal vs Traditional Methods

The Environmental Impact of Laser Rust Removal vs. Chemical Solutions

The method of laser rust removal is increasingly gaining attention for its environmental advantages over traditional chemical solutions. Unlike chemical rust removers, which often contain harmful substances that can leach into the soil and water systems, laser technology relies on focused light to eliminate rust. This process not only produces minimal waste but also reduces the risk of contamination, making it a safer choice for both users and the environment.

Tips: When considering rust removal techniques, evaluate the long-term impact of your choice. Opting for laser methods can lead to a cleaner project site, reducing the need for hazardous waste disposal. Additionally, always ensure that your equipment is maintained regularly to maximize efficiency and minimize energy use.

Moreover, laser rust removal has a higher efficiency rate, often requiring less time and effort compared to chemical alternatives. This means that projects can be completed more quickly while still achieving high-quality results. By choosing laser technology, industries can significantly lower their carbon footprint, contributing to a greener planet without sacrificing effectiveness.

Tips: For optimal results with laser machines, conduct regular training for operators to ensure proper handling and maintenance. This maximizes machine longevity and maintains a low environmental impact throughout its use.

Enhancing Surface Preparation: Benefits of Rust-Free Surfaces in Manufacturing

Rust-free surfaces are crucial in the manufacturing industry, where precision and durability are paramount. By utilizing advanced laser rust removal machines, manufacturers can achieve superior surface preparation, enhancing product quality and reliability. These machines effectively eliminate corrosion without damaging the underlying materials, resulting in a clean and smooth surface ready for further processing. This not only improves the adhesion of coatings and paints but also extends the lifespan of finished products.

Maven Laser Automation Co., Ltd. stands at the forefront of this technological advancement. Founded in 2008 and based in Shenzhen, China, Maven Laser specializes in the design, production, and sales of laser systems tailored to meet the needs of various industries. The company’s commitment to innovation ensures that manufacturers can access the latest automation solutions, empowering them to maintain high-quality production standards while minimizing downtime. Embracing laser rust removal technology offers undeniable benefits, paving the way for more efficient and effective manufacturing processes.

Future Trends: Innovations in Laser Technology for Rust Removal Applications

In recent years, laser technology has revolutionized the rust removal industry, offering more efficient and environmentally friendly solutions. According to a report by Research and Markets, the global market for laser rust removal machines is expected to grow at a CAGR of 15.2% from 2021 to 2026, driven by advancements in laser technology and increasing demand for maintenance-free surfaces. Innovations such as fiber laser technology are leading the way, providing superior precision and effectiveness in rust removal applications compared to traditional methods. These advancements not only improve the quality of surface preparation but also decrease the time and labor required for such tasks.

To maximize the benefits of laser rust removal, it’s crucial to understand best practices in operation and safety. Tip: Always ensure the laser machine is calibrated correctly before use to optimize performance. Moreover, investing in a closed-loop system can enhance efficiency and minimize waste, as these systems recycle abrasive materials while maintaining a clean working environment. Stay informed about the latest trends in laser technology; as mentioned in a study by MarketWatch, AI integration is now being used to train machines for better accuracy and process optimization, pointing towards a more automated future in rust removal.

FAQS

: The global laser cleaning market was valued at USD 0.7 billion in 2024.

The market is expected to expand to USD 1.22 billion by 2033.

The automotive, aerospace, and manufacturing industries are key sectors driving the demand for efficient and eco-friendly rust removal solutions.

Laser rust removal offers non-abrasive, efficient, and precise solutions that do not damage the underlying materials.

High-intensity laser beams create localized heat on rusted surfaces that breaks the bonds between the rust and the underlying material.

Yes, laser rust removal is versatile and can adapt to various surface types and conditions using different laser wavelengths.

Laser rust removal minimizes contamination risks and uses no abrasive materials, making it a more eco-friendly option compared to traditional methods.

The process not only provides a clean finish but also promotes longer-lasting protection against future corrosion, making it ideal for maintaining rust-free surfaces.

Conclusion

The article "Unlocking the Power of Laser Rust Removal Machines: A Comprehensive Guide to Rust-Free Surfaces" explores the significant advantages of using Laser Rust Removal Machines in various industries. It begins by providing essential statistics and insights that illustrate the increasing adoption of these technologies. The science behind laser technology is elaborated, highlighting its effectiveness in removing rust without damaging the underlying material. A cost analysis compares laser rust removal to traditional methods, showcasing its potential for cost savings and efficiency.

Additionally, the article discusses the environmental impact of laser technology versus chemical solutions, emphasizing the eco-friendly nature of laser rust removal. It also outlines the benefits of rust-free surfaces in manufacturing, improving product quality and longevity. Finally, it looks ahead at future trends in laser technology, predicting innovations that will further enhance applications in rust removal, positioning companies like Maven Laser Automation Co., Ltd. at the forefront of this evolving market.

Related Posts

-

Discover the Finest Laser Cleaner: Premium Quality from China's Leading Manufacturing Factory

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Unmatched Quality in Laser Cleaning for Wood Trim from China's Leading Manufacturer

-

Unmatched Manufacturing Excellence in China Featuring the Best Laser Cleaning Head With Advanced Operating Modes

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

Blog Tags:

Olivia

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top