What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

Table of Contents

- The Importance of Laser Welders in Modern Manufacturing Processes

- Key Benefits of Laser Cleaning Technology for Rust Removal

- Comparative Analysis: Laser Welders vs. Traditional Rust Removal Methods

- Efficiency Metrics: How Laser Cleaning Improves Welding Outcomes

- Environmental Impact: The Sustainability of Laser Cleaning Practices

- Future Trends: Innovations in Laser Welding and Cleaning Technologies

- FAQS

- Conclusion

- Related Posts

In the metalworking industry, the efficiency of operations is crucial, particularly when it comes to rust removal and welding processes. A study by the International Institute of Welding indicates that improper rust removal can increase the likelihood of welding defects by up to 40%, leading to higher operational costs and reduced product lifespan. This is where the "Laser Welder Cleaner for Rust Removal and Welding" comes into play. By utilizing advanced laser technology, it offers a precise and efficient method for removing contaminants and preparing surfaces for welding.

Maven Laser Automation Co., Ltd., a leading manufacturer based in Shenzhen, China, has been at the forefront of producing innovative laser systems since its inception in 2008. Their expertise in automation solutions ensures that businesses can achieve optimal efficiency and quality in their welding operations, setting a new standard for excellence in the industry.

The Importance of Laser Welders in Modern Manufacturing Processes

The importance of laser welders in modern manufacturing processes cannot be overstated. As industries evolve, the demand for precision and efficiency in welding has led to the integration of advanced technologies like laser welding. These machines offer several advantages, including the ability to weld materials with minimal thermal distortion, which is crucial in maintaining the integrity of components. This precision not only enhances the quality of the final product but also speeds up the manufacturing process, allowing companies to meet tight production schedules without compromising quality.

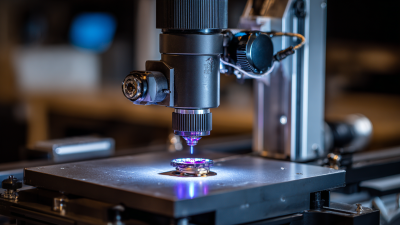

In addition to their welding capabilities, laser welders also play a crucial role in rust removal. A laser welder cleaner effectively eliminates contaminants from metal surfaces, ensuring optimal bonding during the welding process. Traditional rust removal methods can be labor-intensive and time-consuming, but laser technology simplifies this task by delivering concentrated energy that vaporizes rust and other impurities. This dual functionality of laser welders as both welding and cleaning tools demonstrates their significance in modern manufacturing, helping companies achieve higher efficiency and better results in their production lines.

Efficient Rust Removal and Welding with Laser Technology

Key Benefits of Laser Cleaning Technology for Rust Removal

Laser cleaning technology has emerged as a game-changer in the field of rust removal and welding preparation. This innovative method uses high-intensity laser beams to effectively eliminate rust, corrosion, and other surface contaminants without damaging the underlying metals. The precision of laser welders allows for targeted cleaning, ensuring that only the areas requiring attention are treated, thus preserving the integrity of the base material. This is particularly beneficial in industries where surface quality is paramount, such as aerospace and automotive manufacturing.

One of the key benefits of laser cleaning technology is its efficiency. Unlike traditional methods, which may involve abrasive materials or harsh chemicals, laser cleaning reduces waste and minimizes environmental impact. The process is not only fast but can also be automated, leading to significant time and cost savings. Furthermore, as lasers require less operator intervention, the risk of human error is diminished, enhancing both safety and consistency in rust removal. As industries continue to seek cleaner and more sustainable solutions, laser welders stand out as a reliable option that meets these demands while also improving overall operational efficiency.

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding - Key Benefits of Laser Cleaning Technology for Rust Removal

| Feature | Description | Benefit |

|---|---|---|

| High Precision | Laser cleaners target specific areas without damaging surrounding materials. | Ensures clean surfaces for optimal welding and prevents further damage. |

| Environmentally Friendly | Uses no chemicals and generates minimal waste. | Reduces ecological footprint and promotes green technology. |

| Speed and Efficiency | Laser cleaning processes are significantly faster than traditional methods. | Increases productivity and reduces labor costs. |

| Versatility | Effective on various materials including metals, plastics, and composites. | Can be applied in diverse industrial applications for rust removal and surface preparation. |

| Cost-Effectiveness | Lower operational costs in the long run due to reduced material waste and faster cleaning. | Improves ROI and overall efficiency of maintenance operations. |

Comparative Analysis: Laser Welders vs. Traditional Rust Removal Methods

In recent years, laser welding technology has emerged as a game-changer in the realm of rust removal and metal joining. When compared to traditional rust removal methods such as sandblasting or chemical treatments, laser welders stand out for their precision and efficiency. Unlike abrasive techniques that can damage the underlying metal, laser cleaning effectively removes rust and contaminants without altering the base material. This attribute not only preserves the integrity of the workpiece but also reduces the need for extensive post-cleaning processes, thereby saving time and resources.

Moreover, traditional rust removal methods often involve cumbersome setups and involve hazardous chemicals or materials that require careful handling and disposal. In contrast, laser welders utilize a focused beam of light that targets rust particles, ensuring a cleaner work environment. This reduction in waste and potential contamination is increasingly important in industries that prioritize sustainable practices. By understanding the comparative advantages of laser welders over conventional methods, businesses can make informed decisions that enhance both efficiency and safety in their operations.

Efficiency Metrics: How Laser Cleaning Improves Welding Outcomes

Laser cleaning technology has revolutionized the way rust removal is approached before welding processes, significantly enhancing overall efficiency and effectiveness. By using high-intensity laser beams to ablate rust, contaminants, and other surface impurities, this method ensures that the substrate is in optimal condition for welding. Traditional cleaning methods, such as sandblasting or chemical cleaning, can be time-consuming and may lead to material damage. In contrast, laser cleaners provide a precise, targeted solution that not only removes rust but also preserves the integrity of the underlying material.

Furthermore, the efficiency metrics associated with laser cleaning are impressive. Studies show that by reducing surface contamination prior to welding, the laser cleaning process minimizes defects in the weld and improves adhesion. This results in stronger welds with fewer imperfections, decreasing the likelihood of rework and repair in industrial applications. Moreover, the speed of laser cleaning helps reduce downtime, allowing manufacturers to enhance productivity and meet tighter deadlines. As industries continue to seek innovative solutions for improving welding outcomes, laser cleaners are proving to be a game-changer in achieving higher-quality results with less effort and time.

Environmental Impact: The Sustainability of Laser Cleaning Practices

The environmental impact of laser cleaning technologies presents a promising alternative to traditional rust removal methods. Unlike chemical cleaning agents, which often include harsh solvents that can release volatile organic compounds (VOCs) into the atmosphere, laser cleaning is a dry process that does not produce secondary pollutants. According to a report by the National Institute for Occupational Safety and Health (NIOSH), laser cleaning can reduce hazardous waste by up to 90%, significantly lowering the ecological footprint associated with rust removal.

Moreover, the energy efficiency of laser welders is another aspect contributing to their sustainability. A study published in the Journal of Cleaner Production indicates that laser cleaning consumes 50% less energy compared to conventional abrasive cleaning methods. Furthermore, because laser systems are precise and targeted, they reduce material consumption and wear on the surfaces being cleaned. This precision not only extends the life of machinery and infrastructure but also minimizes the need for frequent replacements and repairs, aligning closely with sustainable practices aimed at reducing resource depletion.

Future Trends: Innovations in Laser Welding and Cleaning Technologies

As industries continue to evolve, the need for advanced technologies in welding and cleaning processes becomes increasingly vital. Innovations in laser welding and cleaning technologies are paving the way for more efficient and environmentally friendly solutions. One of the most promising trends is the integration of artificial intelligence (AI) and machine learning into laser systems. These technologies allow for real-time monitoring and adjustments, ensuring optimal performance and precision during the welding process. This not only enhances the quality of the welds but also minimizes material waste and reduces energy consumption.

Another significant development is the improvement in laser cleaning techniques. Traditional cleaning methods often involve harsh chemicals or abrasive materials, which can be harmful to both the environment and the surfaces being cleaned. The introduction of advanced laser cleaners offers a non-invasive alternative that removes rust and contaminants without damaging the underlying material. This not only maintains the integrity of the workpiece but also aligns with the increasing emphasis on sustainable practices across industries. As these innovations continue to arise, they promise to revolutionize the landscape of welding and cleaning, making these processes more efficient and sustainable for the future.

FAQS

: Laser welders are advanced machines that use laser technology for welding processes. They are important because they offer precision and efficiency, which help maintain the integrity of components while speeding up production and improving product quality.

Laser welders effectively eliminate contaminants from metal surfaces by using concentrated energy that vaporizes rust and impurities, which ensures optimal bonding during the welding process.

Laser cleaning technology is efficient, minimizes environmental impact, reduces waste, and preserves the integrity of the base material by precisely targeting only the contaminated areas without damaging the underlying metals.

Laser welding offers more precision and efficiency than traditional methods like sandblasting or chemical treatments, as it removes rust without damaging the underlying metal and reduces the need for extensive post-cleaning processes.

The precision of laser welders is crucial in these industries because surface quality is paramount. It allows for targeted cleaning and welding, which preserves the integrity of components and ensures high-quality production outcomes.

Laser welders produce less waste compared to traditional rust removal methods, require fewer harsh chemicals, and have a smaller carbon footprint due to reduced operator intervention and automation of processes.

By requiring less operator intervention and minimizing the use of hazardous materials, laser welders reduce the risk of human error and enhance safety during rust removal and welding operations.

Yes, laser cleaning technology can be automated, leading to significant time and cost savings while improving consistency and efficiency in rust removal.

Laser welders enhance manufacturing efficiency, allowing companies to meet tight production schedules without compromising on quality due to their fast processing and effective cleaning capabilities.

Businesses can make informed decisions that enhance efficiency, safety, and sustainability in their operations by understanding the comparative advantages of laser welders over conventional rust removal methods.

Conclusion

In the realm of modern manufacturing, the role of the Laser Welder Cleaner For Rust Removal And Welding has become increasingly vital. Laser cleaning technology offers a plethora of advantages over traditional methods, delivering superior efficiency in rust removal while enhancing the overall welding outcomes. The precision of laser systems ensures that surfaces are impeccably prepared, which is crucial in achieving strong welds and prolonging the lifespan of components.

Moreover, the environmental impact of laser cleaning is significantly lower than that of conventional rust removal techniques, aligning with sustainable manufacturing practices. As industries continue to evolve, innovations in laser welding and cleaning technologies, championed by companies like Maven Laser Automation Co., Ltd., will not only improve operational efficiency but also drive the future of eco-friendly solutions in manufacturing.

Related Posts

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Mastering Efficiency: Innovative Approaches to Optimize Your Best Laser Welding Machine Operations

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

A Comprehensive Comparison of 500W Pulsed Laser Cleaner: Performance, Efficiency, and Cost

-

What Makes Best High Power Laser Welding the Ultimate Choice for Global Buyers

-

Exploring Top Alternatives to the Best Fiber Laser Machine for Your Business Needs

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top