Mastering Laser Welder Cutter Cleaner Techniques for Optimal Performance and Efficiency in Your Workshop

Table of Contents

- Understanding the Basics of Laser Welding, Cutting, and Cleaning Technologies

- Essential Equipment and Tools for Efficient Laser Operations in Your Workshop

- Techniques for Maintaining Optimal Laser Welder Performance Over Time

- Common Troubleshooting Solutions for Laser Cutting and Welding Issues

- Best Practices for Safety and Efficiency When Using Laser Equipment

- Innovative Tips for Improving Workflow with Laser Welders and Cutters

- FAQS

- Conclusion

- Related Posts

In the fast-evolving world of manufacturing, precision and efficiency are paramount, particularly when it comes to the operation of Laser Welder Cutter Cleaner systems. Mastering the techniques associated with these powerful tools can significantly enhance performance in any workshop environment.

At Maven Laser Automation Co., Ltd., a leading manufacturer of laser systems and professional automation solutions based in Shenzhen, China, we have been at the forefront of this technology since our inception in 2008. Our expertise in laser case design, production, and sales positions us uniquely to guide you through the complexities of Laser Welder Cutter Cleaner methods. This blog will explore essential techniques and best practices that will enable you to optimize the use of these systems, ensuring high-quality results and maximum operational efficiency in your projects.

Whether you're an experienced technician or new to the scene, enhancing your skills with Laser Welder Cutter Cleaners is crucial to staying competitive in today's industry.

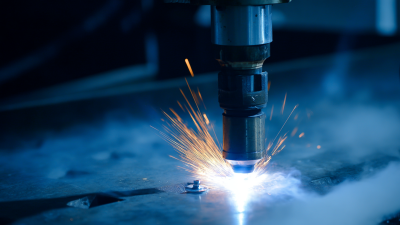

Understanding the Basics of Laser Welding, Cutting, and Cleaning Technologies

Laser welding, cutting, and cleaning technologies have evolved significantly, becoming crucial in various industries for their precision and efficiency. According to a report by MarketsandMarkets, the global laser processing market is expected to grow from USD 9.2 billion in 2021 to USD 12.3 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.1%. This growth is driven by advancements in laser technology that enhance the quality and speed of fabrication processes, making them indispensable tools in modern workshops.

Understanding the fundamentals of these technologies is essential for maximizing workshop performance. Laser welding utilizes highly focused beams of light to join materials with minimal thermal distortion, making it ideal for delicate components in sectors like aerospace and automotive. Additionally, laser cutting offers unparalleled precision, allowing for intricate designs that traditional methods cannot achieve. According to the International Journal of Advanced Manufacturing Technology, laser cutting can reduce material waste by up to 30% compared to traditional cutting methods, thereby boosting overall efficiency. Meanwhile, laser cleaning presents a green alternative to chemical cleaning agents, enhancing surface preparation for treatments while minimizing environmental impact. Collectively, these technologies not only improve operational efficiency but also highlight the need for workshops to stay updated on the latest advancements in laser applications.

Mastering Laser Technologies in Workshop

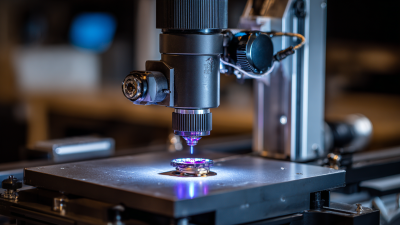

Essential Equipment and Tools for Efficient Laser Operations in Your Workshop

When it comes to enhancing the efficiency of laser operations in your workshop, the right equipment and tools play a crucial role. Incorporating high-quality laser welders, cutters, and cleaners is essential for achieving optimal performance. According to industry reports, the global laser cutting market is projected to reach over $6 billion by 2025, reflecting the increasing demand for precision and efficiency in various applications. Investing in advanced laser technologies not only elevates your operational capacity but also reduces material waste and enhances product quality.

Tips: Regular maintenance of your laser equipment, including cleaning lenses and checking alignment, can significantly improve the precision of your cuts. Additionally, implementing software solutions for design and operation management can streamline your workflow, allowing for quicker adjustments and better resource allocation. Ensure you’re equipped with appropriate safety gear, as safety should always be a priority in high-tech workshops.

Moreover, integrating versatile tools like focus lenses and cutting assistive gases can optimize laser cutting processes. Research indicates that using the right assistive technologies can increase cutting speeds by up to 30%. By consistently updating your toolkit and adopting best practices, you can maximize the performance of your laser operations, ensuring your workshop remains competitive in a fast-evolving industry landscape.

Techniques for Maintaining Optimal Laser Welder Performance Over Time

Maintaining optimal performance of laser welders over time is crucial for achieving high-quality results and ensuring the longevity of equipment. According to a comprehensive industry report by Laser Focus World, proper maintenance can improve operational efficiency by up to 30%. Regularly scheduled inspections and preventative maintenance can help identify potential issues before they escalate, ultimately saving costs and downtime.

One effective technique is to keep the laser optics clean. Contaminants can significantly weaken the laser beam and lead to poor weld quality. It’s advisable to use specialized cleaning solutions designed for laser optics and to establish a routine cleaning schedule. For best results, clean optical surfaces weekly and perform a thorough inspection of the system monthly.

Another important aspect is regular calibration of the equipment. A misaligned laser can not only affect the quality of the welds but also result in excessive wear on the machine components. Industry data suggests that laser systems that undergo calibration every 3 to 6 months exhibit a 25% decrease in repair costs and maintenance requirements. Adopting a proactive approach will help ensure that your laser welder operates at peak performance, delivering precision and reliability in your workshop.

Common Troubleshooting Solutions for Laser Cutting and Welding Issues

Laser cutting and welding can significantly enhance productivity in your workshop, but they are not without their challenges. Common issues such as inconsistent cuts, excessive dross, or inadequate weld penetration can hinder performance. Addressing these problems starts with understanding the fundamental causes, and several troubleshooting solutions can help you achieve optimal results.

One effective tip is to regularly inspect and maintain your laser lens. A dirty or damaged lens can lead to a loss of focus and energy, resulting in poor cutting or welding quality. To clean the lens, use a lens cleaning solution and a soft lint-free cloth. Additionally, ensure that the focus is set accurately; incorrect focus can cause excessive heat dispersion and impact the quality of the cut or weld.

Another aspect to consider is the material being used. Different materials require specific settings for optimal performance. For instance, thicker materials may need slower speeds and higher power to ensure proper penetration. Testing various settings with scrap materials can help in establishing the ideal configurations. Additionally, keep an eye on gas pressure, as insufficient or excessive pressure can lead to unexpected results in both cutting and welding.

Best Practices for Safety and Efficiency When Using Laser Equipment

When working with laser equipment, ensuring safety and efficiency should be a top priority. Proper training and understanding of laser safety protocols are essential to protect yourself and your team from potential hazards. Always wear appropriate personal protective equipment, including safety goggles specifically designed for laser use, to shield your eyes from harmful rays. Additionally, keep your workspace organized and free from flammable materials to prevent accidents.

For optimal performance, it’s crucial to implement best practices in machine operation. Regular maintenance checks will not only improve the efficiency of your laser systems but also prolong their lifespan. Ensure that lenses and mirrors are clean and free of debris, as contamination can lead to poor cutting quality and inefficient energy use. Training your operators on precise machine settings tailored to different materials can greatly enhance the cutting speed and accuracy, resulting in higher productivity.

Lastly, consider establishing a standardized workflow that incorporates safety and efficiency protocols. Documenting procedures for operating laser equipment and performing routine checks will create a safer environment while minimizing downtime. Engaging your team in continuous improvement discussions can also foster innovation and lead to better practices that enhance both safety and operational efficiency in your workshop.

Innovative Tips for Improving Workflow with Laser Welders and Cutters

When it comes to enhancing the performance of laser welders and cutters in your workshop, implementing innovative tips can significantly improve workflow. First, ensure that your workspace is organized and optimized for efficiency. This means having all tools and materials within arm's reach, allowing you to move seamlessly from one task to another.

Utilizing clearly labeled storage solutions can also minimize downtime spent searching for items, which ultimately boosts productivity.

In addition, consider incorporating automation into your operations. Automated systems can handle repetitive tasks, freeing up valuable time for skilled workers to focus on more complex projects. Software solutions that integrate with laser machines also allow for better job scheduling and resource management, leading to smoother transitions between different projects.

Lastly, regular maintenance of your laser equipment cannot be overlooked. A well-maintained machine ensures precision and reduces the likelihood of unexpected breakdowns. Implementing a routine check-up and cleaning schedule will keep your tools in top shape, enhancing both performance and longevity, which is crucial for maintaining efficiency in your workshop.

FAQS

: Laser welding uses highly focused beams of light to join materials with minimal thermal distortion, making it ideal for delicate components in sectors like aerospace and automotive.

Laser cutting offers unparalleled precision and can reduce material waste by up to 30% compared to traditional cutting methods, enhancing overall efficiency.

Laser cleaning provides a green alternative to chemical cleaning agents, enhancing surface preparation while minimizing environmental impact.

Common issues include inconsistent cuts, excessive dross, and inadequate weld penetration, which can hinder performance.

Regularly inspect and maintain your laser lens, ensuring it is clean to prevent loss of focus and energy, and set the focus accurately to avoid excessive heat dispersion.

Different materials require specific settings; for thicker materials, use slower speeds and higher power to ensure proper penetration. Testing various settings with scrap materials can help find the ideal configurations.

Always wear appropriate personal protective equipment like safety goggles designed for laser use, and keep the workspace organized and free from flammable materials.

Implement regular maintenance checks, train operators on precise settings, and establish a standardized workflow with documented procedures to enhance safety and minimize downtime.

Conclusion

In the realm of modern manufacturing, mastering the techniques associated with Laser Welder Cutter Cleaner is essential for achieving optimal performance and efficiency in your workshop. This blog delves into the foundational aspects of laser welding, cutting, and cleaning technologies, equipping readers with the knowledge necessary to enhance their operations. It highlights essential equipment and tools that can streamline laser processes while offering maintenance strategies to uphold laser welder performance over time.

Moreover, the article addresses common troubleshooting solutions for issues that may arise, and outlines best practices to ensure safety and efficiency when operating laser equipment. It also introduces innovative tips aimed at improving workflow with Laser Welders and Cutters, fostering a productive environment that reflects the advancements and expertise demonstrated by leading manufacturers like Maven Laser Automation Co., Ltd. in the laser industry.

Related Posts

-

Mastering Efficiency: Innovative Approaches to Optimize Your Best Laser Welding Machine Operations

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

A Comprehensive Comparison of 500W Pulsed Laser Cleaner: Performance, Efficiency, and Cost

-

The Ultimate Guide to Choosing the Best Laser Welder for Your Mold Repair Needs

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top