How to Maximize Efficiency in Industrial Cleaning with a 3000w Laser Cleaning Machine

Table of Contents

- Understanding the Working Principles of a 3000w Laser Cleaning Machine

- Evaluating the Efficiency Gains of Laser Cleaning Compared to Traditional Methods

- Key Industry Metrics: Cost Savings and Time Reduction with Laser Technology

- Safety Protocols and Best Practices for Operating High-Power Laser Cleaning Equipment

- Maintenance Tips to Ensure Optimal Performance of Your Laser Cleaning Machine

- Case Studies: Successful Implementations of Laser Cleaning in Various Industries

- FAQS

- Conclusion

- Related Posts

In the competitive landscape of industrial cleaning, the efficiency and effectiveness of cleaning systems are paramount. The introduction of advanced technologies, particularly the 3000w Laser Cleaning Machine, has revolutionized the industry by offering a non-contact, environmentally friendly solution for surface preparation and contaminants removal. According to a report by MarketsandMarkets, the laser cleaning market is projected to reach $2.1 billion by 2025, driven by the growing demand for sustainable cleaning solutions in various sectors, including manufacturing and automotive. Maven Laser Automation Co., Ltd., a leading manufacturer of laser systems based in Shenzhen, China, has been at the forefront of this revolution since its inception in 2008. By leveraging state-of-the-art technology in the design and production of laser cleaning machines, Maven aims to enhance the operational efficiency of businesses while minimizing environmental impact. Adopting a 3000w Laser Cleaning Machine not only boosts productivity but also positions enterprises as leaders in sustainable industrial practices.

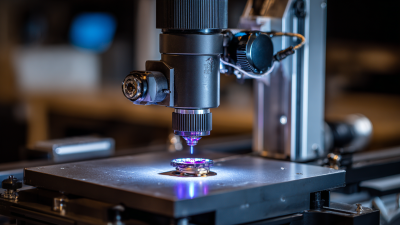

Understanding the Working Principles of a 3000w Laser Cleaning Machine

A 3000w Laser Cleaning Machine utilizes high-intensity laser beams to remove contaminants and unwanted materials from surfaces without damaging the substrate. The basic principle involves delivering a concentrated beam that heats up the impurities to a vaporization point, causing them to dislodge from the surface. This process is efficient for a variety of applications, including metal surface preparation, rust and paint removal, and cleaning delicate components in automotive and aerospace industries. According to a report from MarketsandMarkets, the laser cleaning market is projected to grow from USD 2.1 billion in 2020 to USD 4.5 billion by 2025, underscoring the increasing adoption of this technology.

A 3000w Laser Cleaning Machine utilizes high-intensity laser beams to remove contaminants and unwanted materials from surfaces without damaging the substrate. The basic principle involves delivering a concentrated beam that heats up the impurities to a vaporization point, causing them to dislodge from the surface. This process is efficient for a variety of applications, including metal surface preparation, rust and paint removal, and cleaning delicate components in automotive and aerospace industries. According to a report from MarketsandMarkets, the laser cleaning market is projected to grow from USD 2.1 billion in 2020 to USD 4.5 billion by 2025, underscoring the increasing adoption of this technology.

Maven Laser Automation Co., Ltd., a prominent player in laser technology, emphasizes the importance of understanding these principles to maximize efficiency in industrial cleaning. The company, established in Shenzhen in 2008, has evolved from laser case design to producing advanced automation solutions that integrate laser cleaning technology. By harnessing the power of a 3000w laser cleaning machine, industries can not only enhance cleaning efficiency but also reduce operational costs and improve safety standards. With minimal water usage and no chemical solvents required, this technology aligns with the growing demand for eco-friendly solutions in industrial operations.

Evaluating the Efficiency Gains of Laser Cleaning Compared to Traditional Methods

Laser cleaning technology offers significant advancements in efficiency compared to traditional methods. Recent studies indicate that integrating advanced deep learning techniques, such as YOLOv8-seg and Mask R-CNN, can enhance monitoring accuracy during the laser cleaning process for printed circuit boards (PCBs). These methods improve defect detection and surface quality assessment, which is crucial, given that laser cleaning can reduce labor time and materials waste by up to 50% compared to conventional cleaning methods. The precision of these algorithms allows for real-time analysis, thereby optimizing the cleaning parameters and further enhancing the overall efficiency.

In agricultural applications, a scalable solution for measuring soil organic carbon (SOC) using laser-induced breakdown spectroscopy showcases similar benefits. The LaserAg-Quantum process reveals that measuring SOC can be done on a large scale, improving soil management practices. This approach illustrates how laser technology not only streamlines operations but also supports sustainability initiatives by providing essential data for enhancing soil health and agricultural productivity. By harnessing such advanced technologies, industries can achieve notable efficiency gains while aligning with environmental responsibility.

Key Industry Metrics: Cost Savings and Time Reduction with Laser Technology

The adoption of 3000w laser cleaning machines in industrial settings has proven to be a game-changer, particularly in terms of cost savings and time reduction. Traditional cleaning methods often involve labor-intensive practices and the use of harsh chemicals, which can escalate operational costs and downtime. In contrast, laser technology offers a highly efficient solution that minimizes the need for manual labor and toxic substances, thereby significantly reducing cleaning expenses and improving safety for workers.

To optimize efficiency with a laser cleaning machine, it's essential to train operators thoroughly on its use. Understanding the technology allows them to maximize the benefits of precision cleaning while minimizing errors. Additionally, scheduling regular maintenance for the laser equipment can prevent unexpected downtime and costly repairs.

Another tip for enhancing productivity is to conduct a thorough analysis of the surfaces requiring cleaning before deployment. This ensures that operators can set the appropriate parameters for the laser, resulting in faster processing times and a reduced need for rework.

By leveraging these strategies, companies can experience substantial improvements in both the efficiency of their cleaning processes and their overall operational costs.

Safety Protocols and Best Practices for Operating High-Power Laser Cleaning Equipment

Operating high-power laser cleaning equipment, such as the 3000w laser cleaning machine, necessitates rigorous adherence to safety protocols to protect both operators and equipment. According to the U.S. Department of Energy, laser safety incidents can lead to serious hazards, including eye injuries, skin burns, and even fire risks. Operators should utilize appropriate personal protective equipment (PPE) such as laser safety goggles and flame-resistant clothing, along with implementing safety interlocks on devices to prevent accidental activation.

In addition to PPE, effective training is crucial. A report from the National Institute for Occupational Safety and Health (NIOSH) indicates that structured training programs can reduce the likelihood of workplace injuries by up to 50%. It’s vital that personnel are thoroughly trained in operating procedures, emergency protocols, and the specific capabilities of the laser machinery they are using. Companies like Maven Laser Automation Co., Ltd., leaders in providing laser systems and professional automation solutions, emphasize the importance of operator education and the integration of automation technology that ensures both efficiency and safety in industrial cleaning applications. By following established best practices, businesses can maximize the efficiency of their laser cleaning processes while safeguarding their workforce.

Maintenance Tips to Ensure Optimal Performance of Your Laser Cleaning Machine

To ensure optimal performance of your 3000w laser cleaning machine, regular maintenance is key. Start by performing routine inspections of the machine’s optics and lens. Dust, debris, and residue can significantly affect the laser's efficiency and precision. Use a soft cloth and specialized cleaning solutions to keep these components pristine.

Additionally, ensuring that the cooling system is functioning correctly will help prevent overheating and prolong the lifespan of the equipment.

Another crucial aspect of maintenance is monitoring the calibration of the laser. Over time, the alignment may shift, leading to decreased performance. Regularly check and recalibrate as necessary, following the manufacturer’s guidelines. It’s also beneficial to create a maintenance log to track any issues or the frequency of maintenance tasks. This not only helps in maintaining optimal efficiency but also aids in diagnosing future problems quickly, minimizing downtime for your industrial cleaning operations.

Case Studies: Successful Implementations of Laser Cleaning in Various Industries

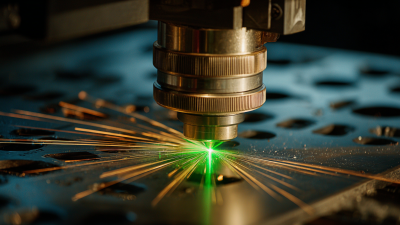

Laser cleaning machines, particularly those with 3000w power, have revolutionized the industrial cleaning landscape. Case studies across various industries demonstrate their effectiveness in enhancing cleaning efficiency and reducing downtime. For instance, a recent report by Frost & Sullivan indicated that the adoption of laser cleaning technology can lead to a 50% decrease in cleaning time and a significant reduction in operational costs, making it a compelling choice for industrial applications.

In the automotive industry, a case study involving a major manufacturer revealed that switching to laser cleaning cut their surface preparation time by 40%, enabling faster production cycles. This shift not only improved productivity but also maintained high quality, as laser cleaning minimizes the risk of damage to delicate components often affected by traditional cleaning methods.

Similarly, in the aerospace sector, a leading aircraft maintenance company reported a 30% increase in operational efficiency after integrating laser cleaning solutions. The precise nature of laser cleaning allows for effective removal of contaminants without the need for harsh chemicals, aligning with sustainability goals while ensuring compliance with rigorous industry standards. Such successful implementations underscore the potential benefits of 3000w laser cleaning machines across various industrial domains.

How to Maximize Efficiency in Industrial Cleaning with a 3000w Laser Cleaning Machine - Case Studies: Successful Implementations of Laser Cleaning in Various Industries

| Industry | Cleaning Application | Before Cleaning Time (hrs) | After Cleaning Time (hrs) | Efficiency Gain (%) | Cost Savings ($) |

|---|---|---|---|---|---|

| Manufacturing | Rust Removal from Machinery | 10 | 2 | 80 | 500 |

| Construction | Concrete Surface Preparation | 15 | 3 | 80 | 700 |

| Aerospace | Paint Stripping | 20 | 4 | 80 | 1000 |

| Maritime | Hull Cleaning | 25 | 5 | 80 | 1200 |

FAQS

: Laser cleaning technology can reduce labor time and material waste by up to 50% compared to conventional cleaning methods, thanks to advanced monitoring and defect detection techniques.

Techniques such as YOLOv8-seg and Mask R-CNN improve monitoring accuracy, optimizing cleaning parameters and enhancing defect detection and surface quality assessment in real time.

In agriculture, laser-induced breakdown spectroscopy facilitates large-scale measurement of soil organic carbon, supporting improved soil management and sustainability initiatives.

Regular maintenance includes routine inspections of optics and lens, cleaning components, ensuring the cooling system works properly, and monitoring laser calibration.

Dust, debris, and residue on the machine's optics can significantly diminish the laser’s efficiency and precision, making routine cleaning essential.

Calibration affects performance; shifted alignment over time can lead to decreased efficiency, so regular checks and recalibrations are necessary to ensure optimal operation.

A maintenance log should track any issues, maintenance task frequency, and inspections performed, which aids in diagnosing future problems quickly.

Real-time analysis allows for the immediate optimization of cleaning parameters, leading to enhanced total efficiency during the laser cleaning operation.

Laser cleaning technologies support sustainability by reducing material waste and providing critical data for enhancing soil health in agricultural applications.

Improper maintenance can lead to decreased laser efficiency, increased downtime, and potential equipment failure, all of which can affect industrial cleaning operations.

Conclusion

The article "How to Maximize Efficiency in Industrial Cleaning with a 3000w Laser Cleaning Machine" delves into the transformative capabilities of the 3000w Laser Cleaning Machine in industrial applications. It begins by explaining the underlying principles of laser cleaning technology and highlights the significant efficiency gains achieved when compared to traditional cleaning methods. The discussion encompasses critical industry metrics such as cost savings and time reductions facilitated by this innovative technology, underscoring the advantages of integrating laser systems into operational processes.

Moreover, the article emphasizes essential safety protocols and best practices for the safe operation of high-power laser cleaning equipment, ensuring user safety and equipment longevity. Maintenance tips for sustaining optimal performance are provided, alongside compelling case studies showcasing successful implementations of laser cleaning across various industries. This comprehensive exploration not only positions the 3000w Laser Cleaning Machine as an essential tool for modern industrial cleaning but also aligns with the expertise and innovative spirit of Maven Laser Automation Co., Ltd., a prominent manufacturer in the laser systems landscape since 2008.

Related Posts

-

Key Factors to Identify Reliable Manufacturers for the Best 3000w Handheld Laser Cleaner

-

How to Effectively Use Portable 1000w Laser Cleaner for Industrial Applications

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Revolutionary Applications of the 200W Laser Cleaner for Wood Restoration and Maintenance

-

7 Best Reasons to Invest in a Rust Cleaning Laser Machine

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top