How to Maximize Efficiency with Laser Cleaner 3000w 5in1 in Industrial Applications

Table of Contents

- Choosing the Right Laser Cleaner 3000w 5in1 Model for Your Industry Needs

- Understanding the Core Functions of the Laser Cleaner 3000w 5in1

- Optimizing Cleaning Techniques for Various Materials in Industrial Settings

- Implementing Safety Protocols When Using Laser Cleaning Equipment

- Integrating the Laser Cleaner 3000w 5in1 into Existing Operations

- Training Staff for Effective Use and Maintenance of Laser Cleaning Systems

- FAQS

- Conclusion

- Related Posts

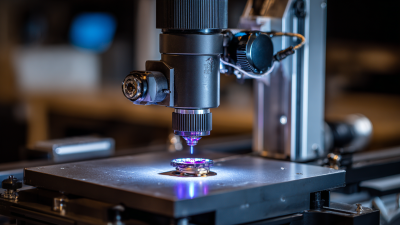

In the ever-evolving landscape of industrial applications, efficiency is paramount for maintaining a competitive edge. The integration of advanced technologies, such as the Laser Cleaner 3000w 5in1, represents a groundbreaking approach to optimizing performance in various cleaning processes. According to a report by MarketsandMarkets, the global laser cleaning market is projected to grow significantly, with a compound annual growth rate (CAGR) of over 15% by 2025, driven by increasing demands for sustainable and efficient cleaning solutions. Maven Laser Automation Co., Ltd., a leading manufacturer of laser systems headquartered in Shenzhen, China, recognizes this trend and is committed to providing innovative automation solutions. Since its inception in 2008, Maven Laser has been at the forefront of the laser market, offering state-of-the-art products that enhance operational efficiency and reduce environmental impact. The Laser Cleaner 3000w 5in1 exemplifies this commitment, providing versatile and powerful cleaning capabilities suitable for a wide range of industrial applications.

Choosing the Right Laser Cleaner 3000w 5in1 Model for Your Industry Needs

When selecting the right Laser Cleaner 3000w 5in1 model for your industry needs, it is essential to first assess the specific applications and materials you will be working with. Different industries, such as automotive, aerospace, and manufacturing, may require varying levels of cleaning intensity, precision, and adaptability. Understanding the types of contaminants—whether they be rust, paint, or grease—can help in choosing a model equipped with the appropriate cleaning modes and attachments.

Moreover, consider the operational efficiency and safety features of the Laser Cleaner 3000w 5in1. Some models come with advanced automation capabilities and programmable settings, which can enhance productivity and reduce manual intervention. Additionally, safety mechanisms like built-in cooling systems and proper shielding ensure that workers are protected while using the equipment. By carefully evaluating these factors, industries can select a laser cleaner that maximizes efficiency and meets their specific cleaning demands effectively.

Understanding the Core Functions of the Laser Cleaner 3000w 5in1

The Laser Cleaner 3000w 5in1 is a versatile tool that significantly enhances efficiency in industrial cleaning applications. Its core functions include rust removal, paint stripping, surface preparation, and the cleaning of complex geometries. According to a report by Research and Markets, the global laser cleaning market is projected to reach $2.95 billion by 2025, reflecting a growing acknowledgment of laser technology in various industries. This trend underscores the importance of understanding the functionalities of systems like the Laser Cleaner 3000w 5in1, which can facilitate improvements in work quality and time management.

The Laser Cleaner 3000w 5in1 is a versatile tool that significantly enhances efficiency in industrial cleaning applications. Its core functions include rust removal, paint stripping, surface preparation, and the cleaning of complex geometries. According to a report by Research and Markets, the global laser cleaning market is projected to reach $2.95 billion by 2025, reflecting a growing acknowledgment of laser technology in various industries. This trend underscores the importance of understanding the functionalities of systems like the Laser Cleaner 3000w 5in1, which can facilitate improvements in work quality and time management.

One of the standout features of the Laser Cleaner 3000w 5in1 is its ability to adapt to different materials and contamination types. The system can operate on metals, plastics, and even delicate substrates without causing damage, making it an essential asset in sectors ranging from automotive to aerospace. Notably, a case study published in the Journal of Industrial Cleaning found that laser cleaning can reduce cleaning time by up to 80% compared to traditional methods, illustrating its effectiveness in boosting operational efficiency. This transformative approach not only aligns with modern sustainability goals by minimizing chemical waste but also leads to lower maintenance costs over time, further justifying its adoption in industrial settings.

Optimizing Cleaning Techniques for Various Materials in Industrial Settings

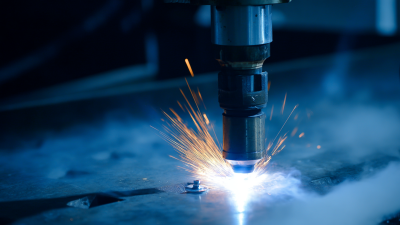

The Laser Cleaner 3000w 5in1 exemplifies cutting-edge technology in the realm of industrial cleaning, particularly when optimizing techniques for various materials. Studies indicate that laser cleaning can increase efficiency by up to 70% compared to traditional methods, dramatically reducing both time and labor costs. This efficiency stems from the ability to fine-tune the laser's intensity and frequency to match specific materials—be it metal, concrete, or fiberglass—ensuring optimal results without damage to the substrate.

In industrial settings, the versatility of the Laser Cleaner becomes apparent. For instance, when dealing with rust removal on steel surfaces, a focused 3000w laser can vaporize contaminants in seconds, while a broader beam can effectively clean larger areas more gently. According to a report from the International Journal of Advanced Manufacturing Technology, laser cleaning methods reduce waste disposal costs by at least 30% due to minimized use of harsh chemicals and water. Additionally, this eco-friendly approach aligns with sustainability goals, as industrial facilities seek to reduce their environmental impact while maintaining high productivity levels.

How to Maximize Efficiency with Laser Cleaner 3000w 5in1 in Industrial Applications

| Material Type | Cleaning Time (mins) | Efficiency (%) | Energy Consumption (kWh) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Steel | 10 | 95 | 1.5 | 6 |

| Aluminum | 8 | 92 | 1.2 | 5 |

| Plastic | 6 | 90 | 0.8 | 4 |

| Glass | 12 | 88 | 1.0 | 8 |

| Wood | 7 | 91 | 0.5 | 3 |

Implementing Safety Protocols When Using Laser Cleaning Equipment

When utilizing the Laser Cleaner 3000w 5in1 in industrial settings, ensuring safety protocols is paramount. According to a report from the International Laser Cleaning Association, industrial laser cleaning, while effective, poses risks related to eye safety and skin protection due to high-intensity laser beams. Implementing stringent safety measures not only protects personnel but also enhances operational efficiency.

Tip: Always ensure that all operators wear appropriate personal protective equipment (PPE), including laser safety goggles and gloves, to protect against potential harm from accidental exposure.

Establishing a safety zone around the cleaning area is also crucial. An analysis by the National Institute for Occupational Safety and Health (NIOSH) highlights that clearly defined operational perimeters reduce the risk of non-operators being exposed to laser radiation and minimize the potential for distractions during operation.

Tip: Regularly conduct safety training and drills for all personnel involved in laser cleaning operations to reinforce the importance of safety protocols and to familiarize everyone with emergency procedures.

Integrating the Laser Cleaner 3000w 5in1 into Existing Operations

Integrating the Laser Cleaner 3000w 5in1 into existing operations can significantly enhance productivity and operational efficiency in industrial settings. This versatile equipment offers a wide range of cleaning capabilities, including rust removal, paint stripping, and surface preparation, making it suitable for various applications. By replacing traditional cleaning methods, companies can not only improve cleanliness but also reduce the time and labor costs associated with maintenance.

To ensure a seamless integration, it is crucial to evaluate current workflows and identify specific areas where the Laser Cleaner can be most beneficial. Training personnel on the proper use of the machine is essential to maximize its potential and ensure safety. Additionally, adapting existing processes to incorporate the Laser Cleaner can lead to better resource allocation, minimized downtime, and an overall enhancement in operational efficiency. By strategically implementing this advanced technology, businesses can stay competitive while maintaining high-quality standards.

Training Staff for Effective Use and Maintenance of Laser Cleaning Systems

To ensure optimal performance of the Laser Cleaner 3000w 5in1 in industrial applications, it's crucial to provide comprehensive training for staff. Employees should be well-versed in the machine's features and operational procedures, which not only enhances efficiency but also minimizes the risk of accidents.

**Tips:** Start with a hands-on workshop that covers the basic functionality of the laser cleaning system. Encourage staff to familiarize themselves with the user manual and undergo simulations to practice troubleshooting common issues. Regular refresher courses can further reinforce knowledge and skills, keeping the team updated on any advancements or changes to operational protocols.

Furthermore, maintenance is equally essential to ensure longevity and effectiveness. Staff should be trained to conduct routine checks, clean the system components, and report any irregularities immediately.

**Tips:** Establish a clear maintenance schedule, and designate specific team members for routine inspections. Using checklists can help streamline this process and ensure that no crucial steps are overlooked. Empowering staff with these skills will lead to better utilization of the laser cleaner and a more productive work environment.

FAQS

: The core functions include rust removal, paint stripping, surface preparation, and cleaning of complex geometries.

It can reduce cleaning time by up to 80% compared to traditional methods, improving productivity and lowering labor costs for maintenance.

It can effectively clean metals, plastics, and delicate substrates without causing damage.

Industries such as automotive, aerospace, and other sectors that require intensive cleaning applications can benefit from its capabilities.

It minimizes chemical waste during the cleaning process, aligning with modern sustainability goals and reducing environmental impact.

Proper training is essential to maximize the machine's potential, ensure safety, and facilitate efficient use within current workflows.

By evaluating current workflows, identifying specific cleaning needs, and adapting processes accordingly, businesses can enhance productivity and minimize downtime.

The global laser cleaning market is projected to reach $2.95 billion by 2025, indicating increasing adoption of laser technology across various industries.

It offers faster cleaning times and lower maintenance costs over time, making it a more cost-effective solution for industrial cleaning needs.

The use of this technology can lead to lower maintenance costs over time by improving cleaning efficiency and reducing the need for traditional cleaning supplies.

Conclusion

The article "How to Maximize Efficiency with Laser Cleaner 3000w 5in1 in Industrial Applications" provides essential insights for industries looking to enhance their cleaning processes. It begins by guiding readers in selecting the appropriate Laser Cleaner 3000w 5in1 model tailored to their specific industry requirements. The article delves into the core functions of this versatile cleaning system and explores optimized techniques for utilizing it on various materials commonly found in industrial settings.

Safety is a paramount concern, and the article emphasizes the importance of implementing strict safety protocols when operating laser cleaning equipment. Furthermore, it discusses how to seamlessly integrate the Laser Cleaner 3000w 5in1 into existing operations, ensuring a smooth transition. Lastly, it highlights the necessity of training staff to effectively use and maintain the laser cleaning systems, thereby maximizing efficiency and productivity across the board.

Related Posts

-

A Comprehensive Comparison of 500W Pulsed Laser Cleaner: Performance, Efficiency, and Cost

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

-

Mastering Laser Welder Cutter Cleaner Techniques for Optimal Performance and Efficiency in Your Workshop

-

5 Essential Tips for Optimizing Your Laser Cleaning Head Rack Performance

Blog Tags:

Olivia

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top