5 Essential Tips for Maximizing Efficiency with Your Rust Cleaning Laser Machine

Table of Contents

- Understanding the Basics of Rust Cleaning Laser Technology

- Choosing the Right Laser Machine for Your Rust Cleaning Needs

- Mastering Operation Techniques for Maximum Cleaning Efficiency

- Maintaining Your Laser Machine for Longevity and Performance

- Safety Measures to Consider While Using a Rust Cleaning Laser

- Exploring Advanced Features for Enhanced Cleaning Results

- FAQS

- Conclusion

- Related Posts

In today's fast-paced industrial environment, efficiency and precision are paramount, particularly in the maintenance and cleaning sectors. The Rust Cleaning Laser Machine has emerged as a revolutionary tool, significantly enhancing the cleaning process for metal surfaces by utilizing advanced laser technology. According to a report by MarketsandMarkets, the laser cleaning market is expected to grow at a compound annual growth rate (CAGR) of over 12% between 2021 and 2026, reflecting a rising demand for effective surface treatment solutions.

Maven Laser Automation Co., Ltd., as a leading manufacturer in this domain since 2008, is at the forefront of developing high-quality laser systems and professional automation solutions. By integrating these cutting-edge technologies, businesses can not only improve their operational efficiency but also reduce their environmental impact, making the Rust Cleaning Laser Machine an essential asset in modern industrial processes.

Understanding the Basics of Rust Cleaning Laser Technology

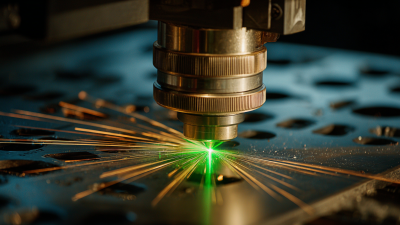

Rust cleaning laser technology has emerged as a game-changer in the maintenance and restoration industries, offering an effective means to eliminate rust while minimizing damage to underlying surfaces. Unlike traditional methods that utilize chemicals or abrasive tools, laser cleaning operates by focusing high-intensity light on rusted areas, causing the contaminants to evaporate or be blown away.

According to a report by MarketsandMarkets, the global laser cleaning market is projected to reach $1.1 billion by 2027, demonstrating rapid growth due to its increasing adoption across various sectors.

The efficiency of laser cleaning machines can be attributed to their precision and versatility. Studies have shown that laser cleaning can reduce cleaning time by up to 50% compared to conventional methods. Furthermore, a research paper published in the Journal of Manufacturing Processes indicates that these machines can clean intricate geometries and hard-to-reach areas without causing damage to the substrate, which is particularly beneficial for the aerospace and automotive industries where component integrity is crucial. As industries strive for higher efficiency and sustainability, understanding the fundamentals of rust cleaning laser technology will be essential for maximizing productivity and minimizing operational costs.

Choosing the Right Laser Machine for Your Rust Cleaning Needs

Choosing the right laser machine for your rust cleaning needs is crucial for achieving maximum efficiency and productivity in your operations. Recent industry reports indicate that laser cleaning technology has grown significantly, with the market expected to reach $300 million by 2026, driven by its effectiveness and eco-friendliness. When selecting a laser machine, consider factors such as the type of rust and the surface material, as different machines are optimized for specific applications.

One essential tip is to assess the power and wavelength of the laser. Higher wattage machines, typically starting at 100 watts, offer faster cleaning capabilities but can be more costly. A thorough evaluation of your rust cleaning requirements will ensure you invest in a machine that delivers optimal results without unnecessary expenditure.

Another tip involves the selection of user-friendly features. Advanced models often incorporate intuitive software and automated settings, enhancing ease of use and reducing operator error. According to a study by the International Journal of Advanced Manufacturing Technology, businesses that adopt such smart laser systems can increase their operational efficiency by up to 30%. Investing in the right equipment can lead to significant gains in productivity and quality of work.

Mastering Operation Techniques for Maximum Cleaning Efficiency

When it comes to maximizing the cleaning efficiency of your Rust Cleaning Laser Machine, mastering operation techniques is crucial. According to a report by the Laser Institute of America, optimizing laser settings can increase cleaning speed by up to 30%. By fine-tuning power intensity, frequency, and pulse duration, operators can ensure a more effective and efficient cleaning process.

One essential tip is to maintain the correct distance between the laser head and the surface being cleaned. The optimal distance can vary depending on the material and contamination type but generally falls between 5 to 10 centimeters. Properly calibrating this parameter allows for enhanced absorption of energy, resulting in superior cleaning results.

Additionally, regular maintenance of the laser machine is vital. A study published in the Journal of Manufacturing Science and Engineering highlights that maintaining clean optics can improve laser performance by up to 20%. Operators should regularly inspect the lens and mirrors, ensuring they are free from contaminants that can impede functionality. Implementing these tips will not only prolong the life of your machine but also optimize its cleaning efficiency significantly.

5 Essential Tips for Maximizing Efficiency with Your Rust Cleaning Laser Machine

This bar chart illustrates the impact of various operational techniques on the cleaning efficiency of a rust cleaning laser machine. Each technique is rated based on its effectiveness.

Maintaining Your Laser Machine for Longevity and Performance

Maintaining the longevity and performance of your laser cleaning machine is crucial for maximizing efficiency in any industrial application. Regular maintenance not only extends the lifespan of the equipment but also ensures that it operates at peak performance. One essential tip is to implement a consistent cleaning schedule for both the laser optics and the machine components. Dust and debris can greatly impact the quality of the laser output, leading to subpar results. By keeping the machine clean, you promote better operational efficiency and reduce the risk of costly repairs.

Another key aspect of maintenance is the proper calibration of your laser system. Over time, minor adjustments may be needed to keep your machine performing optimally. Regular calibration checks can help identify any discrepancies early, allowing for timely corrections. Additionally, utilizing high-quality consumables and ensuring they are replaced when necessary will prevent unnecessary strain on the machine. By focusing on these maintenance practices, you can significantly enhance the reliability and effectiveness of your laser cleaning equipment, ensuring it serves your business needs for years to come.

Safety Measures to Consider While Using a Rust Cleaning Laser

When operating a rust cleaning laser machine, prioritizing safety is crucial to ensure both the operator's well-being and the machine's longevity. According to the Occupational Safety and Health Administration (OSHA), laser systems pose significant risks, including eye injuries and skin burns. It’s vital to wear appropriate personal protective equipment (PPE) such as laser safety goggles and gloves to minimize these hazards. Furthermore, ensuring proper training for operators can significantly reduce the likelihood of accidents; studies show that workplaces with comprehensive training programs reduce incident rates by up to 30%.

In addition to personal safety, maintaining a clutter-free workspace and following operational manuals can lead to increased efficiency. For instance, identifying and using the correct focus settings can enhance performance and achieve quicker results. It's advisable to conduct regular maintenance checks, which not only extend the life of the equipment but also enhance its efficacy. Research indicates that proactive maintenance can improve machinery performance by as much as 15%, making it a crucial practice for anyone utilizing a rust cleaning laser machine.

Moreover, understanding the surrounding environment where the machine is used can help minimize risks. Factors such as ventilation are essential to clear away harmful fumes generated during the cleaning process. Regularly evaluating your work environment against standards set by industry regulations can further ensure safe operations while maximizing machine efficiency.

5 Essential Tips for Maximizing Efficiency with Your Rust Cleaning Laser Machine - Safety Measures to Consider While Using a Rust Cleaning Laser

| Tip | Description | Safety Measure |

|---|---|---|

| Regular Maintenance | Perform routine checks to ensure the laser aligns properly and is functioning at peak performance. | Always power down the machine before starting maintenance. |

| Proper Setup | Set up the machine in a well-ventilated area free of flammable materials. | Use protective barriers to prevent accidental exposure to the laser beam. |

| Training Personnel | Ensure that all operators are adequately trained in laser safety and machine operation. | Provide safety goggles and ensure they are worn during operation. |

| Quality Control | Implement a quality assurance process to monitor cleaning effectiveness. | Conduct tests in a controlled setting before full-scale operations. |

| Effective Settings | Adjust settings based on material type and rust severity for optimal results. | Review machine specifications and safety guidelines before adjustments. |

Exploring Advanced Features for Enhanced Cleaning Results

In the realm of industrial cleaning, Rust Cleaning Laser Machines have become an indispensable tool, offering advanced features that significantly enhance cleaning efficiency and effectiveness. With laser technology, businesses can achieve precise cleaning results without damaging the underlying surface, making it ideal for delicate materials. According to a recent industry report from MarketsandMarkets, the laser cleaning market is projected to reach $460 million by 2025, reflecting a growing recognition of the advantages offered by these machines.

To maximize efficiency, it is crucial to utilize advanced features such as adjustable power settings and automated cleaning modes. Tip one: adjust the laser's power settings based on the material type and cleaning requirements; this not only improves cleaning results but also extends the lifespan of the laser machine. Another vital aspect is regular calibration of the equipment, ensuring consistent performance. Tip two: implement routine maintenance schedules to check alignment and functionality—this practice can lead to a 20% increase in operational efficiency.

Additionally, integrating user-friendly interfaces that allow for real-time monitoring greatly enhances the user experience. Tip three: utilize software that provides analytics on cleaning performance; this data can guide operational adjustments that optimize time and resource usage. By leveraging these advanced features, operators can achieve a cleaner, more efficient outcome with their Rust Cleaning Laser Machines.

FAQS

: Rust cleaning laser technology uses high-intensity light to evaporate or blow away rust, providing an efficient alternative to traditional chemical or abrasive cleaning methods.

Laser cleaning can reduce cleaning time by up to 50% compared to conventional methods, and can clean intricate geometries and hard-to-reach areas without damaging the substrate.

Rust cleaning laser technology is particularly beneficial for the aerospace and automotive industries, where maintaining component integrity is crucial.

Operators should wear personal protective equipment (PPE) such as laser safety goggles and gloves, and undergo proper training to minimize risks like eye injuries and skin burns.

Proactive maintenance can improve machinery performance by up to 15%, extending the equipment's life and enhancing its efficacy.

A clutter-free workspace increases efficiency and reduces the likelihood of accidents by allowing for better operation and focus on the cleaning process.

Adequate ventilation is crucial to clear harmful fumes generated during the cleaning process, ensuring a safer working environment.

Comprehensive training programs can reduce incident rates by up to 30%, enhancing safety and operational effectiveness.

The global laser cleaning market is projected to reach $1.1 billion by 2027, indicating rapid adoption across various sectors.

Using the correct focus settings can enhance the performance of the laser cleaning machine and achieve quicker results during the cleaning process.

Conclusion

In today's fast-paced industrial environment, maximizing efficiency with your Rust Cleaning Laser Machine is crucial for optimal performance and cost-effectiveness. Understanding the fundamentals of rust cleaning laser technology is the first step towards making informed decisions when selecting the right laser machine that suits your specific cleaning needs. Mastering operational techniques will further enhance cleaning efficiency, ensuring that every task is completed swiftly and effectively.

Regular maintenance of your Rust Cleaning Laser Machine is essential for its longevity and sustained performance, while adhering to safety measures is vital to protect both users and equipment. Lastly, exploring advanced features can significantly improve cleaning results, enabling your business to maintain competitive advantages in the industry. Maven Laser Automation Co., Ltd., a prominent player in the laser systems market, provides invaluable insights into these practices, promoting excellence in laser cleaning solutions since its inception in 2008.

Related Posts

-

Key Factors to Identify Reliable Manufacturers for the Best 3000w Handheld Laser Cleaner

-

Revolutionary Applications of the 200W Laser Cleaner for Wood Restoration and Maintenance

-

Unmatched Manufacturing Excellence in China Featuring the Best Laser Cleaning Head With Advanced Operating Modes

-

Innovative Techniques for Using Laser Cleaner on Wood Paint Removal

-

5 Reasons Why the Portable Pulse Laser Cleaner is Essential for Modern Manufacturing

-

Comprehensive Solutions for Efficient Rust Removal with the Best 3000W 4-In-1 Laser Cleaning Machine

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top