Maximizing Productivity with Advanced Industrial Laser Equipment in Modern Manufacturing

Table of Contents

- Understanding the Role of Advanced Laser Technology in Modern Manufacturing

- Key Features of Industrial Laser Equipment that Boost Productivity

- Essential Maintenance Tips for Optimizing Laser Performance

- Integrating Laser Solutions into Existing Manufacturing Processes

- Measuring the Impact of Laser Technology on Manufacturing Efficiency

- Future Trends in Laser Equipment and Their Implications for Production

- FAQS

- Conclusion

- Related Posts

In the rapidly evolving landscape of modern manufacturing, the integration of advanced Industrial Laser Equipment has become a game-changer for enhancing productivity and efficiency. Companies like Maven Laser Automation Co., Ltd., a prominent manufacturer of laser systems and professional automation solutions based in Shenzhen, China, have been at the forefront of this technological revolution since their inception in 2008. With a strong foundation in laser case design, production, and sales, Maven Laser has consistently pushed the boundaries of laser technology to meet the dynamic needs of various industries.

This article delves into the profound impact of advanced industrial laser solutions on manufacturing processes, highlighting their potential to revolutionize workflows, reduce production times, and ultimately drive business success in an increasingly competitive market.

Understanding the Role of Advanced Laser Technology in Modern Manufacturing

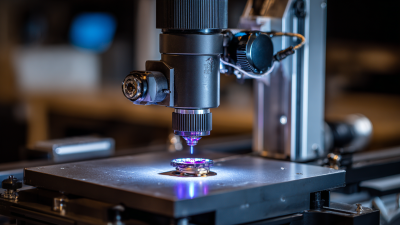

Advanced laser technology plays a pivotal role in modern manufacturing, revolutionizing processes across various industries. By utilizing high-precision laser systems, manufacturers are able to achieve unparalleled accuracy and speed in cutting, welding, and engraving materials. This technology allows for intricate designs and complex geometries to be produced with minimal material waste, thereby enhancing overall efficiency and sustainability in manufacturing practices.

Moreover, the integration of advanced industrial laser equipment fosters automation, which is essential for maintaining a competitive edge in today’s fast-paced market. Lasers can be easily integrated into automated systems, enabling continuous production with reduced downtime. This not only streamlines operational workflows but also minimizes human error, leading to higher product quality. As manufacturers embrace these innovations, they are poised to meet increasing consumer demands while optimizing their production capabilities.

Key Features of Industrial Laser Equipment that Boost Productivity

Advanced industrial laser equipment is transforming modern manufacturing by enhancing productivity through precision and efficiency. One of the key features that significantly boosts productivity is the speed of cutting and engraving. According to a report by the International Society for Optics and Photonics, laser cutting can increase production rates by up to 75% compared to conventional methods. This acceleration in processes allows manufacturers to meet rising market demands without compromising quality.

Advanced industrial laser equipment is transforming modern manufacturing by enhancing productivity through precision and efficiency. One of the key features that significantly boosts productivity is the speed of cutting and engraving. According to a report by the International Society for Optics and Photonics, laser cutting can increase production rates by up to 75% compared to conventional methods. This acceleration in processes allows manufacturers to meet rising market demands without compromising quality.

Another notable feature is the versatility of industrial lasers. Equipment such as fiber lasers, CO2 lasers, and ultra-fast lasers can be utilized across various materials and applications, from metals to polymers. The ability to easily switch between tasks decreases downtime and setup times, which is crucial in just-in-time production environments. A study by the Laser Institute of America indicates that companies integrating advanced laser technologies can experience overall operational cost reductions of up to 30%, thereby allocating resources more effectively and fostering innovation in product development. This adaptability positions businesses to remain competitive in an ever-evolving manufacturing landscape.

Essential Maintenance Tips for Optimizing Laser Performance

Maintaining advanced industrial laser equipment is crucial for optimizing performance and ensuring maximum productivity in modern manufacturing environments. According to a report from the International Laser Manufacturing Association (ILMA), regular maintenance can enhance laser lifespan by up to 30% and reduce operational costs by 20%. This underscores the importance of proactive maintenance strategies in industrial settings.

Key maintenance tips include regularly inspecting optical components for cleanliness and alignment, as these factors significantly affect beam quality and overall performance. A study published by Laser Focus World revealed that misaligned optics can cause a 15% reduction in cutting efficiency. Additionally, keeping cooling systems in optimal condition is essential, as overheating can lead to premature equipment failure. Implementing a comprehensive maintenance schedule that includes these practices can dramatically improve the reliability and efficiency of laser systems, aligning with the growing demands of modern manufacturing.

Integrating Laser Solutions into Existing Manufacturing Processes

Integrating advanced laser solutions into existing manufacturing processes is pivotal for enhancing productivity and operational efficiency in modern industries. The growing laser equipment market, anticipated to witness significant growth from 2024 to 2032, provides manufacturers with a plethora of options tailored to various applications. Notably, CO2 lasers, solid-state lasers, and fiber lasers are among the primary technologies driving this transformation. Their versatility in macro processing tasks, including cutting and welding, allows manufacturers to streamline workflows, reduce material waste, and improve product quality.

Maven Laser Automation Co., Ltd., a frontrunner in the laser systems domain, exemplifies the potential of laser integration in manufacturing. Established in Shenzhen, China, in 2008, Maven Laser is committed to delivering innovative automation solutions that address the evolving needs of the industry. As the laser welding technology market is projected to expand, with an anticipated increase from $747.81 million in 2024 to $894.99 million by 2032, companies like Maven are well-positioned to support this growth by providing state-of-the-art laser solutions that enhance productivity and efficiency across various manufacturing sectors.

Measuring the Impact of Laser Technology on Manufacturing Efficiency

The impact of laser technology on manufacturing efficiency has been transformative, particularly in high-end automotive production where precision is paramount. Advanced laser systems enable manufacturers to conduct quality control and inspection with unmatched accuracy, ensuring that each component meets the exacting standards required for luxury vehicles. For instance, the integration of advanced 3D scanning technology facilitates full-size inspections of complex components in a fraction of the time traditionally required, significantly enhancing productivity.

In addition, the use of laser calibration sensors in manufacturing environments has proven essential in maintaining operational efficiency. These sensors provide real-time data that informs production processes, thereby reducing errors and increasing throughput. Innovative companies are embracing these laser solutions to navigate the complexities of modern manufacturing, demonstrating that the application of cutting-edge laser technology not only elevates precision but also drives overall manufacturing efficiency. The advancements made in laser applications signal a new era where intelligent automation and data-driven precision become the backbone of high-quality production.

Maximizing Productivity with Advanced Industrial Laser Equipment

Future Trends in Laser Equipment and Their Implications for Production

The industrial laser equipment sector is witnessing rapid advancements encouraged by stringent policies and the global shift towards green, low-carbon development. As China emerges as the largest industrial laser market, projected to reach approximately 89.9 billion yuan by 2024, there is a clear trend toward integrating cutting-edge technologies in manufacturing processes. Innovations in laser systems are set to enhance efficiency, reduce costs, and improve production consistency, particularly in critical sectors such as lithium battery manufacturing.

Looking ahead, the next wave of transformation in laser processes is anticipated to focus on optimizing over 2,000 control nodes identified as pivotal pain points in the lithium battery production workflow. This evolution emphasizes a need for high consistency, efficiency, high yield, and lowered production costs. Companies like Maven Laser Automation Co., Ltd., which specialize in professional automation solutions and laser systems, are well-positioned to capitalize on these trends by providing advanced equipment tailored to meet the needs of modern manufacturing, paving the way for increased productivity and innovative production techniques.

FAQS

: One key feature is the speed of cutting and engraving, which can increase production rates by up to 75% compared to conventional methods.

The versatility allows lasers like fiber, CO2, and ultra-fast lasers to work across various materials and applications, reducing downtime and setup times, which is critical in just-in-time production.

Companies can experience overall operational cost reductions of up to 30% by integrating advanced laser technologies.

Regular maintenance can enhance the lifespan of lasers by up to 30% and reduce operational costs by 20%, which is crucial for maintaining productivity.

Key maintenance tips include inspecting optical components for cleanliness and alignment, and keeping cooling systems in optimal condition to prevent overheating.

Misaligned optics can cause a reduction in cutting efficiency by as much as 15%.

Laser technology enhances manufacturing efficiency by enabling quality control and inspection with unmatched precision, particularly important for high-end automotive production.

Laser calibration sensors provide real-time data that informs production processes, reducing errors and increasing throughput.

The advancements signal a new era of intelligent automation and data-driven precision, essential for maintaining high-quality production.

By enhancing productivity and operational efficiency, businesses are better positioned to remain competitive in an ever-evolving market.

Conclusion

In the realm of modern manufacturing, maximizing productivity increasingly relies on advanced Industrial Laser Equipment. This technology plays a crucial role by offering precision and efficiency in various manufacturing processes. Key features of such equipment, including speed and versatility, significantly enhance productivity, while regular maintenance ensures optimal performance. Companies like Maven Laser Automation Co., Ltd. exemplify this advancement by providing cutting-edge laser systems tailored to meet the dynamic needs of the industry.

Integrating Industrial Laser Equipment into existing manufacturing workflows can lead to substantial improvements in efficiency, ultimately streamlining operations. As the industry evolves, measuring the impact of these technologies becomes essential for businesses aiming to maintain a competitive edge. Looking forward, future trends suggest a continued innovation in laser technology, promising even greater implications for production capabilities in the years to come.

Related Posts

-

Unleashing Global Confidence: Premium Laser Markers from China's Leading Factory

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

How to Select Top-Quality Manufacturers for the Best Laser Cutter Machines Globally

-

Ultimate Checklist for Sourcing the Best Laser Metal Welding Solutions Globally

-

7 Best Reasons to Invest in a Rust Cleaning Laser Machine

-

Discover the Finest Laser Cleaner: Premium Quality from China's Leading Manufacturing Factory

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top