Revolutionizing Industrial Maintenance: How Laser Cleaning Machines Change the Game

Table of Contents

- The Transition from Traditional to Laser Cleaning Methods in Industrial Maintenance

- Understanding the Technology Behind Laser Cleaning Machines

- Benefits of Laser Cleaning: Efficiency, Safety, and Environmental Impact

- Comparative Analysis: Laser Cleaning vs. Conventional Methods

- Real-World Applications of Laser Cleaning in Various Industries

- Future Trends in Laser Cleaning Technology and Industrial Maintenance

- FAQS

- Conclusion

- Related Posts

In recent years, the advent of advanced technologies has significantly transformed the landscape of industrial maintenance, with the introduction of the Laser Cleaning Machine emerging as a game-changer. Maven Laser Automation Co., Ltd., a leading manufacturer based in Shenzhen, China, has pioneered the development of innovative laser systems and automation solutions since its inception in 2008. By leveraging cutting-edge laser technology, the Laser Cleaning Machine offers unparalleled efficiency, precision, and eco-friendliness in cleaning processes across various industries. This evolution not only enhances operational productivity but also reduces downtime and maintenance costs, making it an indispensable tool for modern manufacturing and maintenance practices. As we explore the revolutionary impact of Laser Cleaning Machines, it becomes evident that they are reshaping the future of industrial maintenance, delivering significant advantages for businesses striving to maintain a competitive edge in a rapidly evolving marketplace.

The Transition from Traditional to Laser Cleaning Methods in Industrial Maintenance

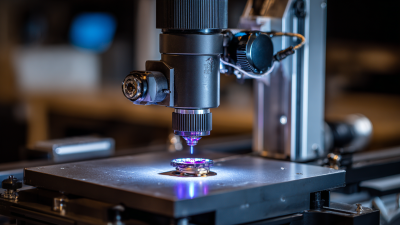

The transition from traditional cleaning methods to laser cleaning technologies is reshaping the landscape of industrial maintenance. Traditional techniques often rely on chemical solvents or abrasive materials, which can be time-consuming and potentially harmful to both the environment and the equipment being serviced. In contrast, laser cleaning machines utilize focused light energy to effectively remove contaminants, rust, and coatings from surfaces without damaging the underlying material. This shift not only enhances the efficiency of maintenance processes but also promotes sustainability in industrial practices.

As the laser cleaning market continues to expand, evident growth trends highlight the increasing adoption of various laser types, including solid-state lasers and fiber lasers, among others. These advancements are driven by the need for cleaner, safer, and more efficient methods of surface preparation in diverse industries. Notably, the ability of laser cleaning to precisely target specific areas minimizes labor and material costs, making it an attractive alternative for businesses aiming to modernize their maintenance operations. With continued innovations and market penetration, laser cleaning methods are positioned to become a standard practice in industrial maintenance settings.

Revolutionizing Industrial Maintenance: How Laser Cleaning Machines Change the Game

| Aspect | Traditional Methods | Laser Cleaning Methods |

|---|---|---|

| Efficiency | Lower efficiency and slower cleaning processes | Higher efficiency with faster cleaning times |

| Environmental Impact | Chemical waste and harmful emissions | Minimal waste and eco-friendly |

| Versatility | Limited to specific surfaces and materials | Highly versatile across various surfaces |

| Cost | Frequent expenses on materials and labor | Lower long-term costs with reduced material use |

| Safety | Potential hazards from chemicals | Safer with reduced chemical exposure |

| Surface Finish Quality | May leave residues and damage surfaces | Produces superior surface quality without damage |

Understanding the Technology Behind Laser Cleaning Machines

Laser cleaning technology is revolutionizing industrial maintenance by offering a highly efficient and environmentally friendly alternative to traditional cleaning methods. By utilizing high-intensity laser beams, these machines effectively remove contaminants such as rust, paint, grease, and minerals from surfaces without the need for chemicals or abrasives. According to a recent industry report by MarketsandMarkets, the laser cleaning market is anticipated to grow from USD 1.5 billion in 2023 to over USD 3 billion by 2028, highlighting the increasing adoption of this cutting-edge technology across various sectors.

Laser cleaning technology is revolutionizing industrial maintenance by offering a highly efficient and environmentally friendly alternative to traditional cleaning methods. By utilizing high-intensity laser beams, these machines effectively remove contaminants such as rust, paint, grease, and minerals from surfaces without the need for chemicals or abrasives. According to a recent industry report by MarketsandMarkets, the laser cleaning market is anticipated to grow from USD 1.5 billion in 2023 to over USD 3 billion by 2028, highlighting the increasing adoption of this cutting-edge technology across various sectors.

The technology behind laser cleaning machines leverages the principle of photothermal interaction, where the energy from the laser beam is absorbed by contaminants, causing them to evaporate or be blown away by the force generated. This process is not only faster than conventional cleaning techniques but also significantly reduces the amount of waste generated. A study from the European Commission noted that laser cleaning can increase operational efficiency by up to 50% compared to traditional methods. As industries continue to seek sustainable and cost-effective solutions, laser cleaning machines are poised to become a standard in industrial maintenance practices.

Benefits of Laser Cleaning: Efficiency, Safety, and Environmental Impact

Laser cleaning technology is transforming industrial maintenance by offering increased efficiency, safety, and a positive environmental impact. This process uses advanced laser systems to remove contaminants such as rust, rubber, and scale without the need for harsh chemicals. Recent advancements highlight its application in aviation, where a combination of laser and liquid energy has enabled rapid and eco-friendly runway reconstruction, promoting a low-carbon approach to rubber removal. Such innovations demonstrate that laser cleaning not only enhances operational efficiency but also aligns with sustainable manufacturing goals.

Implementing laser cleaning can significantly reduce waste and energy consumption, and its non-contact nature minimizes the risk of damaging surfaces. Here are a few tips to maximize the benefits of laser cleaning in industrial applications: First, ensure that the laser parameters are accurately set according to the material type for optimal results. Second, integrate dynamic monitoring technologies to track the cleaning process, ensuring efficiency and effectiveness while adhering to safety regulations. By following these practices, industries can harness the full potential of laser cleaning while contributing to environmental stewardship.

Revolutionizing Industrial Maintenance: The Impact of Laser Cleaning Machines

This chart illustrates the benefits of laser cleaning technology in industrial maintenance, focusing on efficiency, safety, and environmental impact.

Comparative Analysis: Laser Cleaning vs. Conventional Methods

The laser cleaning market is set to experience significant growth from 2024 to 2032, driven by the increasing demand for efficient and eco-friendly cleaning solutions in industrial maintenance. Unlike traditional cleaning methods that often rely on abrasive materials or harsh chemicals, laser cleaning utilizes concentrated light to remove contaminants, rust, and paint without damaging the underlying surface. According to industry reports, the global laser cleaning market size is projected to reach approximately $500 million by 2032, showcasing a compound annual growth rate (CAGR) of over 8% during the forecast period.

A comparative analysis between laser cleaning and conventional methods highlights the numerous advantages of adopting laser technology. Laser cleaning not only reduces operational costs by minimizing the need for consumables but also enhances safety and environmental sustainability. For instance, traditional methods can produce hazardous waste and require extensive safety measures, while laser cleaning generates minimal waste and utilizes no toxic chemicals. As a leading manufacturer in laser systems, Maven Laser Automation Co., Ltd. is at the forefront of this revolution, providing innovative automation solutions that cater to the evolving demands of the industrial sector.

Real-World Applications of Laser Cleaning in Various Industries

Laser cleaning technology is making significant strides across various industries by offering efficient and environmentally friendly solutions for surface preparation and maintenance. In the aerospace sector, for instance, laser cleaning machines are employed to remove coatings, scale, and contaminations from aircraft components. According to a report from MarketsandMarkets, the laser cleaning market is projected to grow from USD 1.0 billion in 2021 to USD 1.6 billion by 2026, indicating a robust demand for this technology driven by the need for precision and safety in aerospace applications.

In the manufacturing industry, the use of laser cleaning machines has transformed processes traditionally reliant on chemical solvents and abrasive methods. The automotive sector, for example, benefits from laser cleaning when preparing surfaces for welding or painting, significantly reducing the time and costs associated with manual cleaning. A study by ResearchAndMarkets found that laser cleaning can decrease surface preparation time by up to 50%, showcasing its efficiency and value. This innovative approach not only minimizes waste but also aligns with increasing sustainability efforts within the industry, making it a game changer in industrial maintenance.

Future Trends in Laser Cleaning Technology and Industrial Maintenance

The future of industrial maintenance is being reshaped by advancements in laser cleaning technology, which offers a more efficient and environmentally friendly alternative to traditional methods. As industries increasingly face stringent regulations regarding waste management and emissions, laser cleaning machines present a sustainable solution that minimizes debris and chemical runoff. The precision of laser cleaning not only improves safety but also enhances operational efficiency, allowing for quicker maintenance cycles while extending the lifespan of machinery and equipment.

Emerging trends indicate a growing integration of automation and artificial intelligence in laser cleaning systems. This evolution enables real-time data collection and analysis, ensuring that maintenance processes are both predictive and responsive. With the ability to tailor cleaning parameters to specific industrial needs, future laser cleaning technologies promise to streamline operations further. Additionally, advancements in portability and scalability of these machines are likely to make laser cleaning accessible for a wider range of applications, from heavy manufacturing to delicate components in the aerospace sector, thereby revolutionizing the very foundations of industrial maintenance.

FAQS

: Laser cleaning technology involves the use of high-intensity laser beams to effectively remove contaminants such as rust, paint, grease, and minerals from surfaces without the need for chemicals or abrasives.

Laser cleaning offers increased efficiency, safety, and environmental sustainability. It reduces waste and energy consumption, minimizes the risk of surface damage, and eliminates the need for harsh chemicals.

Laser cleaning operates on the principle of photothermal interaction, where the energy from the laser beam is absorbed by contaminants, causing them to evaporate or be blown away by the generated force.

Laser cleaning is increasingly adopted across various sectors, including aviation, where it is used for eco-friendly runway reconstruction and rubber removal.

The laser cleaning market is anticipated to grow from USD 1.5 billion in 2023 to over USD 3 billion by 2028, indicating rising adoption of this technology.

To maximize benefits, users should accurately set laser parameters according to the material type and integrate dynamic monitoring technologies to track the cleaning process for efficiency and safety.

Laser cleaning reduces hazardous waste generation and avoids the use of toxic chemicals, aligning with sustainable manufacturing practices and promoting environmental stewardship.

Laser cleaning can increase operational efficiency by up to 50% compared to traditional methods, making it a faster and more effective solution for industrial maintenance.

Maven Laser Automation Co., Ltd. is a leading manufacturer of laser systems, providing innovative automation solutions that meet the evolving demands of the industrial sector.

The laser cleaning market is projected to reach approximately $500 million by 2032, reflecting a compound annual growth rate (CAGR) of over 8% from 2024 to 2032 due to increasing demand for eco-friendly cleaning solutions.

Conclusion

The article "Revolutionizing Industrial Maintenance: How Laser Cleaning Machines Change the Game" explores the significant shift from traditional cleaning methods to advanced laser cleaning technologies in industrial maintenance. It begins by examining the fundamental differences between these approaches, highlighting the superiority of Laser Cleaning Machines in terms of efficiency and effectiveness. The technology that powers these machines leverages focused laser beams to remove contaminants without damaging underlying surfaces, showcasing their innovative design and application.

The benefits of using Laser Cleaning Machines extend beyond mere efficiency; they promote safety and minimize environmental impact, making them a viable solution for modern industries. A comparative analysis underscores their advantages over conventional cleaning methods, while real-world applications illustrate the versatility of laser cleaning across various sectors. Finally, the article anticipates future trends in laser cleaning technology, emphasizing how Maven Laser Automation Co., Ltd., a leader in this field, is positioned to drive these advancements and meet the evolving needs of industrial maintenance.

Related Posts

-

7 Tips for Choosing the Best Pulse Laser Cleaning Machine for Rust Removal

-

Unmatched Manufacturing Excellence in China Featuring the Best Laser Cleaning Head With Advanced Operating Modes

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

5 Essential Tips for Maximizing Efficiency with Your Rust Cleaning Laser Machine

-

What is the Efficiency of 200w Pulse Laser Cleaning Machine for Wood Applications

-

How to Maximize Efficiency in Industrial Cleaning with a 3000w Laser Cleaning Machine

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top