5 Essential Tips for Optimizing Your Laser Cleaning Head Rack Performance

Table of Contents

- Maximizing Laser Efficiency: Understanding Optimal Cleaning Head Alignment

- The Role of Beam Quality in Enhancing Cleaning Precision and Speed

- Impact of Cooling Systems on Laser Cleaning Head Longevity and Performance

- Calculating Ideal Power Settings for Different Material Surfaces and Contaminants

- Evaluating Maintenance Routines to Prolong Cleaning Head Service Life

- FAQS

- Conclusion

- Related Posts

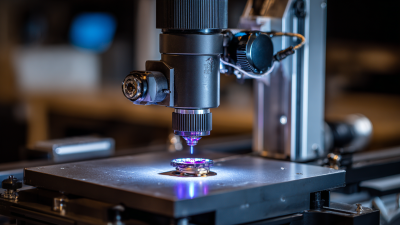

As industries increasingly turn to advanced laser technologies for precision cleaning and material processing, the performance of the Laser Cleaning Head Rack plays a critical role in achieving optimal results. According to a report by Markets and Markets, the global laser cleaning market is projected to reach $1.29 billion by 2025, driven by the demand for environmentally friendly and efficient cleaning solutions. This growth underscores the importance of investing in high-quality equipment and optimizing performance to stay competitive. At Maven Laser Automation Co., Ltd., a leading manufacturer of laser systems and professional automation solutions since 2008, we understand the significance of enhancing the functionality of your Laser Cleaning Head Rack. This blog will provide you with five essential tips to ensure your laser cleaning systems operate at their peak efficiency, thereby maximizing productivity and maintaining the integrity of your processes.

Maximizing Laser Efficiency: Understanding Optimal Cleaning Head Alignment

Achieving optimal laser efficiency is paramount for businesses relying on laser cleaning technology. Proper alignment of the cleaning head can dramatically enhance cleaning performance while minimizing energy consumption. According to a recent industry report, effective laser cleaning systems can reduce operational costs by up to 30% when equipment is calibrated correctly. Maven Laser Automation Co., Ltd., a leader in the laser systems arena, emphasizes the importance of precision engineering in their products, which are designed to ensure peak performance and efficiency from installation through to daily use.

Tip 1: Regularly check and adjust the angle of the laser cleaning head. A misaligned head can lead to uneven cleaning surfaces and potential damage to the substrate, resulting in costly rework.

Tip 2: Ensure that the focus of the laser beam is optimized. An incorrectly focused beam can waste energy and reduce cleaning effectiveness. Consult the specifications provided by Maven Laser for the ideal focal length for your specific cleaning applications.

By prioritizing the alignment and focusing of your laser cleaning head, you can not only enhance efficiency but also extend the lifespan of your equipment, maximizing your investment in technology.

The Role of Beam Quality in Enhancing Cleaning Precision and Speed

The quality of the laser beam plays a crucial role in determining the efficiency and effectiveness of your cleaning processes. A well-optimized beam can significantly enhance the precision and speed of the cleaning results, reducing time and cost. According to a recent industry report, lasers with a higher beam quality can achieve up to a 30% improvement in cleaning speed, allowing for quicker turnaround times in industrial applications.

To ensure optimal performance of your laser cleaning equipment, focus on maintaining a clean and stable beam path. Regularly inspect optical components for damage or contamination, as these factors can degrade beam quality. Additionally, utilizing advanced optics can help to refine the beam profile, enhancing cleaning accuracy and resulting in less material loss on the substrate being cleaned.

Furthermore, consider the wavelength of your laser. Different materials respond uniquely to varying wavelengths, and selecting the appropriate one can improve cleaning precision. For example, a report by the Laser Institute of America indicates that using a wavelength close to the absorption peak of the contaminant can lead to a 50% increase in efficiency for specific applications. Integrating this understanding into your laser cleaning strategy will help you achieve superior results and maximize your equipment's potential.

Impact of Cooling Systems on Laser Cleaning Head Longevity and Performance

When it comes to optimizing the performance of laser cleaning head racks, one of the most crucial factors to consider is the impact of cooling systems. A well-designed cooling system not only enhances the efficiency of your laser cleaning process but also significantly extends the lifespan of the laser cleaning head. Overheating can lead to diminished performance, decreased cleaning effectiveness, and eventually result in costly repairs or replacements. By maintaining optimal temperatures, you ensure that the components function reliably under demanding operational conditions.

Incorporating advanced cooling technologies, such as water cooling or air cooling systems, can greatly improve the thermal management of laser cleaning heads. These systems work by dissipating heat generated during operation, keeping the laser components at a stable temperature. Additionally, regular maintenance and monitoring of the cooling system are essential to detect any potential issues before they escalate. By investing in a robust cooling solution and ensuring its proper functionality, you can optimize the performance of your laser cleaning head rack, resulting in more efficient cleaning operations and lower downtime.

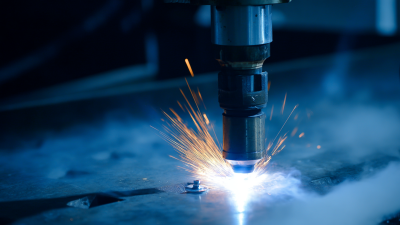

Calculating Ideal Power Settings for Different Material Surfaces and Contaminants

When optimizing the performance of your laser cleaning head rack, understanding how to calculate ideal power settings based on different material surfaces and contaminants is crucial. Research indicates that the optimal power output can vary significantly depending on the type of surface being cleaned. For instance, studies from the Laser Institute of America suggest that metal surfaces generally require a power setting of between 100 to 200 watts for effective removal of rust and scale without damaging the substrate. In contrast, more delicate surfaces, such as plastics or composites, may only need around 30 to 50 watts to avoid risks of melting or abrasion.

Additionally, the type of contaminant also plays a vital role in determining the right power setting. A report by the Society for Optics and Photonics highlights that contaminants like paint or heavy oil residues might necessitate higher power settings—sometimes up to 300 watts—while lighter contaminants, such as dust or soot, can be effectively removed with less than 100 watts. Regularly calibrating and adjusting your laser cleaning head rack based on these factors will not only enhance cleaning efficiency but will also prolong the lifespan of your equipment.

Optimizing Laser Cleaning Head Rack Performance

Evaluating Maintenance Routines to Prolong Cleaning Head Service Life

When considering the maintenance routines for optimizing your laser cleaning head performance, it’s important to adopt strategies that not only enhance efficiency but also prolong the service life of your equipment. Regular and systematic maintenance can significantly reduce the wear and tear associated with high-intensity cleaning tasks. For instance, evaluating the lifecycle of components and implementing a preventive maintenance schedule can ensure that all parts of the cleaning head operate at their peak performance, ultimately resulting in lower long-term operational costs.

Moreover, drawing insights from recent studies on sustainability and lifecycle management can provide valuable guidance. Just as innovative maintenance strategies like bitumen-stabilized ballast improve the durability and efficiency of railway systems, similar principles can be applied to laser cleaning technology. Focusing on the repair and refurbishment of cleaning heads rather than outright replacement fosters a more sustainable approach and enhances the equipment's longevity. By incorporating design choices that facilitate easier maintenance and deploying eco-design methods, users can expect to optimize their laser cleaning operations while contributing to a circular economy.

5 Essential Tips for Optimizing Your Laser Cleaning Head Rack Performance

| Tip | Description | Frequency | Impact on Service Life |

|---|---|---|---|

| Regular Inspection | Inspect the cleaning head for signs of wear and tear. | Weekly | High |

| Cleaning Procedures | Develop a routine for cleaning the laser components. | Bi-weekly | Medium |

| Calibration Checks | Ensure laser parameters are correctly calibrated. | Monthly | High |

| Component Replacements | Replace worn components promptly. | As needed | Very High |

| User Training | Provide staff training on proper use of the equipment. | Annually | Medium |

FAQS

: Proper alignment of the cleaning head can enhance cleaning performance and minimize energy consumption, potentially reducing operational costs by up to 30% when calibrated correctly.

Regularly check and adjust the angle of the laser cleaning head and ensure that the focus of the laser beam is optimized according to the specifications provided by Maven Laser for your specific applications.

A well-optimized laser beam enhances cleaning precision and speed, with higher beam quality lasers achieving up to a 30% improvement in cleaning speed.

Regularly inspect optical components for damage or contamination and utilize advanced optics to refine the beam profile, which enhances cleaning accuracy.

Different materials respond uniquely to varying wavelengths, so selecting a wavelength close to the absorption peak of the contaminant can significantly improve cleaning precision, with a potential efficiency increase of up to 50%.

The optimal power output varies significantly by surface type; metal surfaces usually require 100 to 200 watts, while delicate surfaces like plastics may need only 30 to 50 watts to prevent damage.

Different contaminants require different power settings; for instance, heavier contaminants such as paint or oil residues may need up to 300 watts, while lighter ones like dust can be removed with less than 100 watts.

Regularly calibrating and adjusting the laser cleaning head based on the specific materials and contaminants being cleaned will enhance efficiency and prolong equipment lifespan.

Conclusion

In today's competitive landscape, optimizing the performance of your Laser Cleaning Head Rack is essential for achieving maximum efficiency and precision in laser cleaning applications. This blog outlines five critical tips to enhance your cleaning processes. First, understanding the importance of optimal cleaning head alignment can significantly increase laser efficiency. Additionally, maintaining high beam quality is crucial for improving both cleaning precision and speed.

Moreover, the cooling systems play a pivotal role in extending the longevity and performance of the Laser Cleaning Head Rack. It’s also vital to calculate ideal power settings tailored to various material surfaces and contaminants. Lastly, establishing effective maintenance routines can ensure the service life of your cleaning head is prolonged, making your operations more reliable and cost-effective. With Maven Laser Automation Co., Ltd.'s commitment to quality, these tips will help you maximize your laser system's potential.

Related Posts

-

Discover the Finest Laser Cleaner: Premium Quality from China's Leading Manufacturing Factory

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

A Comprehensive Comparison of 500W Pulsed Laser Cleaner: Performance, Efficiency, and Cost

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

-

Mastering Laser Welder Cutter Cleaner Techniques for Optimal Performance and Efficiency in Your Workshop

Blog Tags:

Olivia

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top