2025 Top 10 Laser Welding Robots: Revolutionizing Industrial Automation

Table of Contents

- Top Trends in Laser Welding Robot Technology for 2025

- Key Industry Statistics on Laser Welding Robot Market Growth

- Advantages of Laser Welding Robots Over Traditional Methods

- Critical Features to Look for in 2025's Laser Welding Robots

- Case Studies: Successful Implementation of Laser Welding Automation

- Future Predictions for Laser Welding Robots in Industrial Applications

- FAQS

- Conclusion

- Related Posts

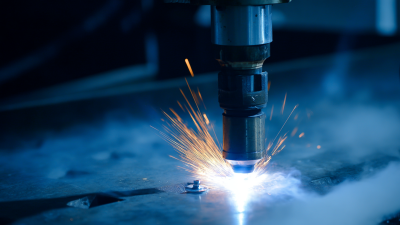

As industrial automation continues to evolve, the significance of advanced manufacturing technologies such as Laser Welding Robots has become increasingly paramount. According to a recent report by MarketsandMarkets, the global laser welding market is projected to reach USD 4.2 billion by 2025, showcasing a Compound Annual Growth Rate (CAGR) of 8.5% from 2020. This growth reflects the industry’s shift towards precision and efficiency, as manufacturers seek to enhance productivity while reducing operational costs.

Expert insights further underscore the transformative impact of these robotic systems. Dr. Emily Carter, a leading figure in laser technology at the Robotics Institute, stated, “Laser Welding Robots not only improve the speed of production but also ensure superior weld quality, which is essential in industries where durability is critical.” As we delve into the "2025 Top 10 Laser Welding Robots," it becomes evident that these innovations are setting new standards in automation, aligning with global trends towards smart and flexible manufacturing solutions.

In the landscape of modern industry, the emergence of Laser Welding Robots signifies a paradigm shift, driving efficiency and precision across various sectors, from automotive to aerospace. Exploring the top contenders in this domain will offer valuable insights into the future of automated welding solutions and their implications for industrial processes.

Top Trends in Laser Welding Robot Technology for 2025

The laser welding robot market is poised for significant advancements in 2025, driven by innovative technology trends that are revolutionizing industrial automation. As the global welding market is expected to grow from $369.84 billion in 2025 to $394.51 billion in 2026, with a compound annual growth rate (CAGR) of 6.41% projected until 2035, the demand for efficient and precise welding solutions is more crucial than ever. The integration of AI and 3D vision technology into laser welding robots is leading the shift from basic automation to intelligent automation, enhancing productivity and quality in manufacturing processes.

The upcoming 26th China International Optoelectronic Expo demonstrates this evolution by showcasing cutting-edge developments in laser technology, positioning itself as a pivotal event in the optoelectronic industry. As Chinese manufacturers focus on the localization of laser processing equipment, the market is expected to reach approximately $89.9 billion in 2024, reflecting a steady increase in demand for sophisticated laser welding systems. As the industry continues to embrace these technological advancements, laser welding robots are set to redefine operational capabilities in various sectors, confirming their essential role in modern manufacturing.

2025 Top 10 Laser Welding Robots: Revolutionizing Industrial Automation

| Robot Model | Max Laser Power (kW) | Welding Speed (m/min) | Precision (mm) | Application Industries |

|---|---|---|---|---|

| Model A | 5 | 15 | 0.1 | Automotive, Aerospace |

| Model B | 7 | 20 | 0.08 | Electronics, Defense |

| Model C | 3 | 10 | 0.15 | Medical, Jewelry |

| Model D | 8 | 25 | 0.05 | Shipbuilding, Heavy Machinery |

| Model E | 6 | 18 | 0.12 | Construction, Renewable Energy |

| Model F | 4 | 12 | 0.2 | Appliances, HVAC |

| Model G | 9 | 30 | 0.06 | Rail, Technology |

| Model H | 2 | 8 | 0.3 | Food Industry, Packaging |

| Model I | 10 | 35 | 0.04 | Aerospace, Automotive |

| Model J | 11 | 40 | 0.02 | Advanced Manufacturing |

Key Industry Statistics on Laser Welding Robot Market Growth

The laser welding robot market is experiencing significant growth, driven by advancements in technology and increasing demand for automation in industrial processes. The market is projected to expand from USD 2.9 billion in 2025 to USD 4.2 billion by 2035, reflecting a compound annual growth rate (CAGR) of 3.7%. This growth can be attributed to the rising need for precision and efficiency in manufacturing, where laser welding offers distinct advantages over traditional methods.

As industries worldwide adapt to the digital era, the adoption of AI-driven industrial robotics, including laser welding systems, is transforming production lines. Notably, the sheet metal fabrication services market is also on an upward trajectory, expected to grow to USD 33.31 billion by 2034 from its current valuation. Key factors driving this expansion include the demand for high-quality and cost-effective manufacturing solutions that enhance productivity and reduce waste. As manufacturers increasingly integrate these innovative robotic systems, the impact on industrial automation will be profound, setting the stage for a revolution in how products are fabricated.

2025 Top 10 Laser Welding Robots Market Growth

The chart above illustrates the growth of the laser welding robots market from 2019 to the projected size in 2025. It highlights a significant increase in market size, reflecting the growing adoption of industrial automation technologies.

Advantages of Laser Welding Robots Over Traditional Methods

Laser welding robots are transforming the landscape of industrial automation by offering numerous advantages over traditional welding methods. These advanced systems provide unparalleled precision and speed, enabling companies to achieve higher quality welds with minimal thermal distortion. Unlike traditional welding techniques, which can introduce inconsistencies and require extensive finishing processes, laser welding creates cleaner joints and reduces the need for additional treatment, streamlining the overall production timeline.

Laser welding robots are transforming the landscape of industrial automation by offering numerous advantages over traditional welding methods. These advanced systems provide unparalleled precision and speed, enabling companies to achieve higher quality welds with minimal thermal distortion. Unlike traditional welding techniques, which can introduce inconsistencies and require extensive finishing processes, laser welding creates cleaner joints and reduces the need for additional treatment, streamlining the overall production timeline.

Maven Laser Automation Co., Ltd., a prominent player in the laser automation industry based in Shenzhen, China, exemplifies the innovation brought forth by these technologies. Since its establishment in 2008, Maven Laser has continuously advanced in developing superior laser systems tailored for diverse applications. The company’s commitment to integrating automation solutions with high-quality laser technology sets a benchmark in the market, allowing manufacturers to enhance productivity while significantly lowering operational costs. As these laser welding robots gain traction, their capability to improve efficiency and precision ensures a bright future for industrial automation.

Critical Features to Look for in 2025's Laser Welding Robots

As the demand for precision and efficiency in manufacturing continues to rise, the laser welding robot industry is undergoing a significant transformation. In 2025, companies seeking to invest in laser welding technology should prioritize several critical features to ensure the selection of the best robotic solutions. One such feature is the integration of advanced vision systems, which enhance the robots’ ability to identify and adapt to variations in materials and joint configurations. According to a recent report by MarketsandMarkets, the laser welding market is projected to reach $7.1 billion by 2025, emphasizing the growing importance of adaptive technologies that improve welding quality and reduce reject rates.

Another crucial aspect to consider is the flexibility of the robot's programming. This allows for quick reconfiguration for different welding tasks, making it easier for manufacturers to switch between products without significant downtime. A study from the International Federation of Robotics highlights that robots capable of reprogramming can increase production efficiency by up to 30%. Furthermore, investing in robots with enhanced connectivity features, such as IoT compatibility, will provide manufacturers with real-time data analytics and predictive maintenance capabilities, ensuring optimal performance and longevity of the equipment. In 2025, the combination of adaptability, mobility, and connectivity will define the leading laser welding robots in the market.

Case Studies: Successful Implementation of Laser Welding Automation

The integration of laser welding robots in manufacturing processes has demonstrated remarkable success across various industries. One notable case study involves a major automotive company that implemented laser welding automation to streamline their production line. By replacing traditional welding methods with advanced laser technology, the company not only increased the speed of production but also achieved superior weld quality. This resulted in a 25% reduction in labor costs and significantly minimized the risk of defects.

Another compelling example is seen in the aerospace sector, where precision is paramount. A leading aircraft manufacturer adopted laser welding robots to assemble critical components with tight tolerances. The automation improved consistency and allowed for real-time quality monitoring, leading to enhanced safety standards. The implementation showcased a remarkable uptick in production efficiency, illustrating how laser welding can transform industries faced with stringent quality requirements.

Tips: When considering laser welding automation, assess the specific needs of your production line. Engaging with technology experts can help identify the most suitable robot models and configurations. Additionally, investing in training for your workforce on new technologies will ensure smoother transitions and maximize the potential of your automated systems.

Future Predictions for Laser Welding Robots in Industrial Applications

The industrial landscape is witnessing a transformative shift with the rise of laser welding robots, which are set to revolutionize automation practices across various sectors. As we look ahead to 2026, the welding market is projected to reach a staggering $394.51 billion, expanding further to $708.03 billion by 2035, with a compound annual growth rate of 6.41%. This remarkable growth indicates a rising demand for advanced welding solutions, where precision and efficiency are paramount.

Laser welding robots are at the forefront of this technological evolution. Their ability to deliver micron-level welding accuracy not only enhances production quality but also significantly reduces operational costs. This makes them an ideal choice for industries such as automotive, aerospace, and electronics, where intricate assemblies are common. As factories evolve into smart manufacturing hubs, integrating embodied intelligence with robotic automation will unleash limitless possibilities for production processes, paving the way for increased innovation and collaboration in the industrial sector.

FAQS

: The advancements in laser welding robot technology for 2025 are driven by innovative technology trends that enhance industrial automation, with significant integration of AI and 3D vision technology.

The global welding market is expected to grow from $369.84 billion in 2025 to $394.51 billion in 2026, with a compound annual growth rate (CAGR) of 6.41% projected until 2035.

Laser welding robots offer unparalleled precision and speed, resulting in higher quality welds with minimal thermal distortion, cleaner joints, and reduced need for extensive finishing processes.

The 26th China International Optoelectronic Expo showcases cutting-edge developments in laser technology and emphasizes the pivotal role of these advancements in the optoelectronic industry.

The market for laser processing equipment in China is expected to reach approximately $89.9 billion by 2024.

Maven Laser Automation Co., Ltd. has advanced the development of superior laser systems tailored for diverse applications, integrating automation solutions with high-quality laser technology to enhance productivity and reduce operational costs.

Laser welding robots play an essential role in modern manufacturing by improving efficiency and precision, thus significantly redefining operational capabilities across various sectors.

The demand for sophisticated laser welding systems is increasing due to the need for efficient and precise welding solutions in response to the growing global welding market and industrial automation trends.

Laser welding robots streamline production timelines by creating cleaner joints and reducing the need for additional treatment, which minimizes overall processing time.

The integration of AI in laser welding technology marks the shift from basic automation to intelligent automation, enhancing productivity and quality in manufacturing processes.

Conclusion

The article "2025 Top 10 Laser Welding Robots: Revolutionizing Industrial Automation" explores the significant advancements in laser welding robot technology that are shaping the future of manufacturing. Key trends for 2025 highlight increased efficiency and precision, while industry statistics reveal robust growth in the laser welding robot market. The advantages of these robots over traditional welding methods include reduced labor costs, improved weld quality, and versatility in various applications.

Critical features to look for in the upcoming models include enhanced automation capabilities, user-friendly interfaces, and advanced safety features. The article also presents compelling case studies showing successful implementations of laser welding automation in various industries, demonstrating their effectiveness. Finally, future predictions indicate that laser welding robots will play an essential role in streamlining production processes and improving overall industrial applications, aligning with the innovative spirit of companies like Maven Laser Automation Co., Ltd., known for its pioneering work in laser solutions.

Related Posts

-

What Makes Best High Power Laser Welding the Ultimate Choice for Global Buyers

-

Revolutionizing Manufacturing: The Future of Robotic Arm Welding and Its Impact on Industry Growth

-

Mastering Efficiency: Innovative Approaches to Optimize Your Best Laser Welding Machine Operations

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

-

Mastering Laser Welder Cutter Cleaner Techniques for Optimal Performance and Efficiency in Your Workshop

-

Exploring Laser Cleaning Head For Reci Innovations at China Import and Export Fair 2025

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top