Top 10 Laser Cleaner Machines for Effective Rust Removal?

Table of Contents

- Top 10 Laser Cleaner Machines for Effective Rust Removal

- Understanding the Technology Behind Laser Cleaning Machines

- Key Benefits of Using Laser Cleaners for Rust Removal

- Factors to Consider When Choosing a Laser Cleaner

- Comparison of Laser Cleaning Machines: Efficiency and Cost Analysis

- Case Studies: Successful Applications of Laser Cleaning Technology

- Future Trends in Laser Cleaning for Industrial Applications

- FAQS

- Conclusion

- Related Posts

When it comes to getting rid of rust, a Laser Cleaner Machine really can be a total game changer. These days, they're pretty amazing tools—offering a safe, non-toxic, and surprisingly efficient way to tackle rust and corrosion on all sorts of surfaces. Companies like CleanLasers and RustAway have developed some cool machines that use laser tech to deliver seriously impressive results.

Using a Laser Cleaner Machine can actually save you both time and some serious elbow grease. Instead of relying on old-school methods like scrapers, nasty chemicals, or sandblasting, lasers use focused light to zap away the rust. Plus, their precision means you don’t have to worry much about damaging the surface underneath—that’s a huge plus.

That said, it’s worth keeping in mind that not all machines are created equal. Cost and maintenance can vary a lot, and some models might not quite fit your specific needs or environment. It’s a smart move to evaluate what you really need and what your budget allows. Trying out a few different options before you commit could end up saving you hassle—and money—down the line. The right machine isn’t just about getting rid of rust; it’s about making your life a whole lot easier in the long run.

Top 10 Laser Cleaner Machines for Effective Rust Removal

When it comes to rust removal, laser cleaning machines are an advanced solution. They use high-energy laser beams to target rust and contaminants. This technique is efficient and environmentally friendly. It's also precise, minimizing damage to the underlying material.

Choosing the right laser cleaner can be tricky. Consider your needs first. Do you have large surfaces to clean? Or are you working on delicate items? Understanding the scope of your project is essential. Also, check the machine’s power settings. Higher power often means faster cleaning but could harm sensitive surfaces. The right balance is key.

**Tip:** Always test on a small area first. This helps gauge how the material reacts. Take breaks during heavy cleaning. Continuous use can lead to overheating or fatigue.

While laser cleaners excel at removing rust, they might not eliminate deep corrosion. Assess what you’re dealing with. Some rust might need additional treatment. So, keep expectations realistic. Using a combination of methods can lead to better results.

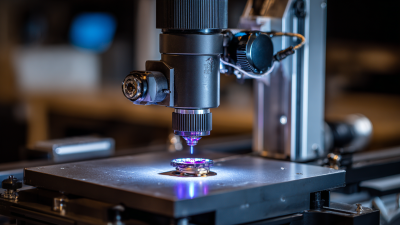

Understanding the Technology Behind Laser Cleaning Machines

Laser cleaning machines use advanced technology to remove rust and contaminants. They harness focused beams of light to achieve this task. The process involves pulsing high-energy lasers that interact with the surface material. This can create heat, causing rust or coatings to break down.

Understanding the mechanism behind laser cleaning reveals its efficiency. The laser's energy targets specific materials, ensuring minimal damage to the substrate. It’s not just about rust removal; it also prepares surfaces for further treatment.

However, the learning curve can be steep. Not every rust type reacts the same way. Users may find that adjustments are necessary for different tasks. Focusing too much energy can lead to unwanted etching. Finding the right balance takes practice and patience. Each project might present unique challenges that require thoughtful adjustments.

Key Benefits of Using Laser Cleaners for Rust Removal

Laser cleaners are revolutionizing rust removal. Their precision makes them stand out from traditional methods. Unlike abrasive techniques, laser cleaning targets only the rust without damaging the underlying surface. This ensures a cleaner result, and the risk of corrosion reduces significantly.

Using a laser cleaner is environmentally friendly. The process doesn’t require harsh chemicals, making it a safer option for users and the planet. Often, this method results in minimal waste, particularly when comparing it to sandblasting. However, learning how to operate these machines effectively still needs attention. Users must be trained properly to avoid mishaps.

Time efficiency is another key benefit. Laser cleaning can reduce rust removal time significantly. This leads to faster project completion. Yet, it is essential to consider the equipment's initial cost. Some might find it a financial challenge. Therefore, weighing long-term advantages against immediate costs is crucial. The benefits are clear, but practical considerations remain.

Factors to Consider When Choosing a Laser Cleaner

When selecting a laser cleaner machine for rust removal, several factors come into play.

Power output is critical. Machines with higher wattage are often more effective in removing rust. However, higher power can lead to overheating. A balance is essential.

Material compatibility is also important. Different materials react differently to laser cleaning.

For instance, metals may absorb energy effectively, while plastics might not. Understanding the material type you will clean is crucial.

Additionally, the machine’s weight and portability should be considered. A heavier unit may offer more stability but could hinder maneuverability in tight spaces.

Tips: Always check the user manual for recommended settings based on material type. This can save you time and improve outcomes.

Regular maintenance is key to longevity. Cleaning the laser lens helps ensure optimal performance.

Safety measures cannot be overlooked. Laser cleaning produces fumes and tools should be used in well-ventilated areas.

Depending on the thickness of the rust, you might need multiple passes, which can be frustrating. Take your time to plan your approach.

Comparison of Laser Cleaning Machines: Efficiency and Cost Analysis

When it comes to laser cleaning machines, efficiency is a key factor. These machines use high-intensity lasers to remove rust and contaminants. They work by vaporizing the unwanted materials. This process is fast, but the effectiveness varies.

Cost analysis reveals significant differences among models. Some machines offer higher efficiency at a premium price. Others are more budget-friendly but may take longer to achieve results. It's essential to consider both initial investment and long-term maintenance costs. Always evaluate the specific needs of your project.

Not all machines are suitable for every application. Some users report challenges with portability. Heavy models can be difficult to maneuver. Additionally, while laser cleaning is generally precise, uneven surfaces may pose obstacles. Reflecting on these aspects can help buyers make informed decisions.

Case Studies: Successful Applications of Laser Cleaning Technology

Laser cleaning technology has gained traction in various industries for its efficiency in rust removal. In one case study, an old industrial machinery part was cleaned using a laser cleaner. The rust was thick, making traditional methods ineffective. The laser system successfully removed the rust, restoring the part to its original state. However, the operator noted that precision is crucial. Some areas were missed due to improper angle adjustments.

In another example, a shipyard implemented laser cleaning on its vessels. The results were impressive, as heavy rust and marine growth were eliminated quickly. Workers reported a significant reduction in time spent on maintenance. Yet, they also mentioned a learning curve. The team had to adapt to the new technology and ensure proper training on safety measures. Despite some struggles, the shift to laser cleaning proved beneficial overall. The technology demonstrated its potential to revolutionize rust removal processes across different sectors.

Top 10 Laser Cleaner Machines for Effective Rust Removal

| Model | Power Output (Watts) | Weight (kg) | Cleaning Speed (m²/h) | Application Areas |

|---|---|---|---|---|

| Model A | 1000 | 15 | 5 | Industrial Machinery |

| Model B | 1500 | 18 | 4 | Marine Equipment |

| Model C | 2000 | 20 | 6 | Automotive Industry |

| Model D | 2500 | 22 | 7 | Heavy Equipment |

| Model E | 3000 | 25 | 8 | Construction Machinery |

Future Trends in Laser Cleaning for Industrial Applications

The future of laser cleaning in industrial applications looks promising. As more industries adopt this technology, efficiency is becoming paramount. Laser cleaning machines have proven effective in rust removal, but their potential extends beyond that. They can also tackle paint, contaminants, and unwanted coatings with precision.

One key area for growth is automation. Integrating AI with laser cleaning systems could lead to faster processes. However, this also poses challenges. Machines must adapt to varying surface conditions and materials. There’s a learning curve for operators too. Adequate training is essential to maximize these advancements.

Environmental sustainability is another trend shaping the industry. Laser cleaning is less harmful than traditional methods. There’s no need for harsh chemicals, reducing waste. This shift requires a mindset change among industries, pushing them towards greener alternatives. Overall, while the future seems bright, careful consideration of these challenges is necessary for progress.

FAQS

: Natural ingredients often have fewer side effects. They can be gentler on the skin.

Observe how your skin behaves throughout the day. Does it feel oily, dry, or combination?

Yes, but always dilute them with a carrier oil. Test for allergies on a small area first.

Generally, once or twice a week works best. Over-exfoliation can lead to irritation.

Choose a moisturizer that suits your skin type. Look for hydrating ingredients like hyaluronic acid.

Assess what works for you. Sometimes, using fewer products can yield better results.

Yes, daily sunscreen protects against UV damage. Even cloudy days require protection.

Absolutely. A balanced diet can enhance skin health. Junk food may trigger breakouts.

Avoid touching your face. Use gentle products and stay hydrated.

Yes, try natural oils like coconut or olive oil. Honey is also very moisturizing.

Conclusion

The article "Top 10 Laser Cleaner Machines for Effective Rust Removal" explores the innovative technology behind laser cleaning machines and their effectiveness in rust removal. The piece highlights the numerous benefits of using laser cleaners, including their efficiency, precision, and environmental friendliness compared to traditional cleaning methods.

Key factors to consider when selecting a laser cleaner machine are also discussed, such as power levels, portability, and maintenance requirements. A comparative analysis evaluates the efficiency and cost of various models available in the market. Furthermore, the article presents case studies showcasing successful applications in different industrial settings. As the industry evolves, the future trends in laser cleaning technology suggest broader applications and advancements, reinforcing the laser cleaner machine's potential in revolutionizing rust removal and surface preparation processes.

Related Posts

-

Discover the Finest Laser Cleaner: Premium Quality from China's Leading Manufacturing Factory

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

5 Essential Tips for Optimizing Your Laser Cleaning Head Rack Performance

-

Revolutionizing Industrial Maintenance: How Laser Cleaning Machines Change the Game

-

Innovative Applications of Laser Cleaner Machines in Industrial Maintenance

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top