2025 Top Laser Welder Innovations for Precision and Efficiency

Table of Contents

- Advancements in Laser Technology for Enhanced Precision in Welding

- Innovative Laser Welding Techniques to Improve Efficiency in Manufacturing

- Smart Automation in Laser Welding: Revolutionizing Industry Standards

- Eco-Friendly Laser Welding Solutions: Sustainability Meets Innovation

- Real-Time Monitoring Systems for Precise Laser Welding Operations

- Future Trends: Integrating AI and Machine Learning in Laser Welding Applications

- FAQS

- Conclusion

- Related Posts

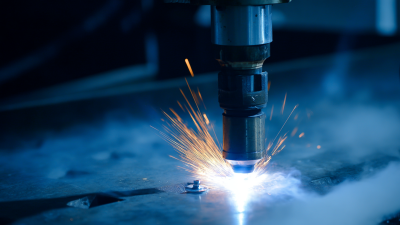

As the manufacturing landscape evolves, the demand for high-precision and efficient joining solutions continues to grow.

Laser welding technology has emerged as a pivotal development, enabling industries to achieve superior weld quality with minimal thermal distortion. According to a recent industry report by MarketsandMarkets, the global laser welding market is projected to reach USD 4.9 billion by 2025, growing at a CAGR of 6.5%. This growth is driven by advancements in laser welder innovations that enhance productivity and reliability in various sectors, including automotive, aerospace, and electronics.

Laser welding technology has emerged as a pivotal development, enabling industries to achieve superior weld quality with minimal thermal distortion. According to a recent industry report by MarketsandMarkets, the global laser welding market is projected to reach USD 4.9 billion by 2025, growing at a CAGR of 6.5%. This growth is driven by advancements in laser welder innovations that enhance productivity and reliability in various sectors, including automotive, aerospace, and electronics.

Maven Laser Automation Co., Ltd., a leading manufacturer of laser systems and professional automation solutions based in Shenzhen, China, has been at the forefront of this technological revolution since its inception in 2008. With a strong background in laser case design, production, and sales, Maven Laser is dedicated to developing cutting-edge laser welder solutions that meet industry demands for precision and efficiency. As we look ahead to 2025, the integration of smart technology and automation in laser welding processes promises to further elevate performance standards, making it essential for manufacturers to stay updated on the latest innovations in laser welder technology.

Advancements in Laser Technology for Enhanced Precision in Welding

The advancements in laser technology are reshaping the welding industry, significantly enhancing precision and efficiency. According to a recent report by MarketsandMarkets, the global laser welding market is projected to reach $2.33 billion by 2025, growing at a CAGR of 6.7% from 2020. This growth is driven by the rising demand for high-quality welds in industries such as automotive and aerospace, where precision is critical. Modern laser welders utilize fiber optics and solid-state lasers, which provide improved beam quality and focus, allowing for tighter tolerances and cleaner welds compared to traditional welding methods.

Furthermore, the integration of automation and artificial intelligence in laser welding systems is revolutionizing manufacturing processes. As highlighted in a research paper by the American Welding Society, automated laser welding can enhance productivity by up to 50% and significantly reduce the risk of human error. Technologies such as real-time monitoring and adaptive feedback systems enable welders to adjust parameters on-the-fly, ensuring consistent quality and reducing waste. These innovations not only streamline operations but also lead to substantial cost savings, making laser welding an increasingly attractive option for manufacturers focused on precision and efficiency.

Innovative Laser Welding Techniques to Improve Efficiency in Manufacturing

In 2025, laser welding technology has emerged as a vital component driving efficiency and precision in manufacturing. Recent trends indicate a shift towards more automated and innovative laser welding techniques that significantly enhance productivity. For instance, studies have shown that the implementation of advanced laser welding systems can increase manufacturing output by up to 30%, while also improving the quality of welds and reducing overall cycle times. This is crucial as industries strive to meet growing demands for high-quality products at lower costs.

Moreover, the participation of over 680 startups in laser technology innovation is reshaping the market landscape. Notable advances include the integration of artificial intelligence and machine learning into laser welding processes, which facilitate real-time adjustments and optimizations. Data indicates that manufacturers adopting these technologies can expect a reduction in material waste by approximately 25%, aligning with sustainability goals integral to modern manufacturing practices. The forthcoming Butech Exhibition further underscores the potential of these innovations, showcasing top manufacturers that are leading the charge in laser welding solutions tailored to the heavy equipment sector.

2025 Top Laser Welder Innovations for Precision and Efficiency

| Innovation | Description | Efficiency Improvement (%) | Precision Level (µm) | Application Area |

|---|---|---|---|---|

| Fiber Laser Technology | Utilizes fiber optics to produce high-quality laser beams. | 30% | 15 | Metal Fabrication |

| Pulse Laser Welding | Enables precise control over energy input for thinner materials. | 25% | 10 | Electronics Assembly |

| Hybrid Laser Welding | Combines laser and arc welding for optimal results. | 40% | 20 | Automotive Manufacturing |

| Robotic Laser Welding | Automates welding processes for improved speed. | 35% | 12 | Shipbuilding |

| Laser Beam Welding (LBW) | Uses concentrated laser beams to join materials. | 20% | 5 | Aerospace Components |

Smart Automation in Laser Welding: Revolutionizing Industry Standards

The evolution of laser welding technology has reached new heights, particularly with the advent of smart automation systems. These innovations are not only enhancing the precision of welding processes but also streamlining operations across various industrial sectors. By integrating advanced algorithms and machine learning, modern laser welders are capable of adapting to real-time variables such as material type, thickness, and environmental conditions. This flexibility ensures optimal performance and minimizes human error, setting a new benchmark for quality in manufacturing.

Furthermore, smart automation in laser welding is facilitating significant improvements in productivity. Automated systems can operate continuously, thereby increasing output while reducing labor costs and operational downtime. The use of robotics in conjunction with laser technology allows for intricate welding tasks to be performed with remarkable speed and consistency. As the industry shifts towards more automated solutions, businesses that adopt these innovations will not only improve their operational efficiency but also position themselves as leaders in a competitive market, ultimately driving the evolution of industry standards.

Eco-Friendly Laser Welding Solutions: Sustainability Meets Innovation

The rising focus on sustainable innovation in the laser welding sector aligns perfectly with the trends seen in the broader automotive and manufacturing landscapes. A recent report indicates that the global plastic welding equipment market is projected to grow from $1.652 billion in 2024 to $2.675 billion by 2033, underscoring an increasing demand for efficient and eco-friendly welding methods.

This shift not only enhances manufacturing precision but also significantly reduces waste and energy consumption through the implementation of advanced technologies.

Moreover, the automotive industry continues to embrace specialty polymers as a replacement for traditional metals, leading to notable weight reductions and improved fuel efficiency. These materials, recognized for their lightweight and low-carbon attributes, have been awarded for their contributions to sustainable practices. The synergy between laser welding innovations and these advanced materials presents industries with opportunities to adopt well-integrated solutions that marry efficiency with environmental responsibility, ultimately spearheading a transformation towards a more sustainable manufacturing future.

Real-Time Monitoring Systems for Precise Laser Welding Operations

The laser welding market is on an impressive trajectory, projected to reach USD 4.2 billion by 2035, with a compound annual growth rate (CAGR) of 3.7% from 2025. This growth is driven by technological advancements, particularly in real-time monitoring systems that enhance precision in laser welding operations. These innovative systems enable manufacturers to track parameters during the welding process, minimizing errors and ensuring consistent quality. By leveraging these technologies, businesses can optimize their workflow and significantly reduce scrap rates.

Moreover, the integration of artificial intelligence in welding processes has revolutionized the industry. AI-driven models facilitate the development of data-informed strategies, allowing for predictive maintenance and real-time adjustments to welding operations. This shift not only addresses the growing shortage of skilled welders but also enhances overall operational efficiency. Manufacturers who adopt these cutting-edge technologies are better equipped to meet the demands of various sectors, including medical device manufacturing, where precision is critical. As the landscape of laser technology evolves, staying updated with these trends will be vital for businesses aiming to maintain a competitive edge.

Future Trends: Integrating AI and Machine Learning in Laser Welding Applications

The integration of artificial intelligence (AI) and machine learning in laser welding applications marks a pivotal shift in the industry, enhancing precision and efficiency. By harnessing these advanced technologies, manufacturers can optimize welding parameters in real-time, adapting to varying material conditions and geometries. This not only reduces the likelihood of defects but also increases the speed and quality of the welding process, making it a vital tool for modern manufacturing.

Recent trends within laser technology include the development of intelligent monitoring systems that leverage AI to analyze data during the welding process. These systems help in predictive maintenance, ensuring equipment operates at peak performance while minimizing downtime. Moreover, startups are emerging with innovative solutions that focus on automation and smart integration, addressing the growing demand for seamless workflows in various industries. These advancements not only streamline operations but also enable businesses to stay competitive in a rapidly evolving market landscape.

FAQS

: Laser welding technology is expected to increase manufacturing output by up to 30%, improve weld quality, and reduce cycle times, thus enhancing overall efficiency and precision in manufacturing.

Over 680 startups are participating in laser technology innovation, introducing advanced systems that integrate artificial intelligence and machine learning for real-time process adjustments, significantly reshaping the market landscape.

Manufacturers utilizing these systems can reduce material waste by approximately 25%, which aligns with modern sustainability goals in manufacturing practices.

Smart automation enhances precision and streamlines operations by using advanced algorithms and machine learning to adapt to real-time variables, thereby minimizing human error and ensuring optimal performance.

Automated systems can operate continuously, leading to increased output, reduced labor costs, and minimized operational downtime, significantly improving productivity in welding operations.

The focus on sustainable innovation is driving demand for efficient and eco-friendly welding methods, which lead to reduced waste and energy consumption, transforming the manufacturing landscape towards sustainability.

The automotive industry is increasingly adopting specialty polymers over traditional metals, resulting in lighter materials that enhance fuel efficiency and contribute to sustainable manufacturing practices.

The integration of robotics with laser technology allows for intricate welding tasks to be performed quickly and consistently, boosting operational efficiency and setting new industry standards.

The global plastic welding equipment market is projected to grow from $1.652 billion in 2024 to $2.675 billion by 2033, indicating a strong demand for innovative welding solutions.

Innovations in laser welding facilitate the use of lightweight, low-carbon materials, promoting sustainable practices while merging efficiency and environmental responsibility in manufacturing.

Conclusion

The article "2025 Top Laser Welder Innovations for Precision and Efficiency" explores the latest advancements in laser technology designed to enhance welding precision. It highlights innovative techniques that improve manufacturing efficiency, emphasizing the role of smart automation in revolutionizing industry standards. Furthermore, eco-friendly solutions are discussed, showcasing how sustainability and innovation can coexist in laser welding. Real-time monitoring systems are examined as crucial tools for ensuring precise operations, while future trends focus on the integration of AI and machine learning within laser welding applications.

As Maven Laser Automation Co., Ltd. continues to lead in the laser systems market, it exemplifies the pursuit of these cutting-edge developments. Located in Shenzhen, China, Maven is committed to delivering high-quality automation solutions that align with the evolving landscape of laser welding technology, ensuring both precision and efficiency in manufacturing processes.

Related Posts

-

Mastering Laser Welder Cutter Cleaner Techniques for Optimal Performance and Efficiency in Your Workshop

-

Exploring the Future of Manufacturing: How Laser Welders are Revolutionizing Precision Engineering

-

The Ultimate Guide to Choosing the Best Laser Welder for Your Mold Repair Needs

-

Mastering Efficiency: Innovative Approaches to Optimize Your Best Laser Welding Machine Operations

-

What is the Role of Laser Welder Cleaner in Efficient Rust Removal and Welding

-

What is the Innovation Behind 100w Laser Jewelry Welder Technology

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top