Ultimate Guide to Mastering the 200w Jewelry Spot Welder for Perfect Joints

Table of Contents

- Understanding the Basics of 200w Jewelry Spot Welders

- Key Features and Specifications of a 200w Spot Welder

- Step-by-Step Guide to Setting Up Your Jewelry Spot Welder

- Techniques for Achieving Strong and Precise Joints

- Common Mistakes to Avoid When Using a Spot Welder

- Maintenance Tips for Prolonging the Life of Your Spot Welder

- FAQS

- Conclusion

- Related Posts

In the rapidly evolving world of jewelry manufacturing, the importance of precision and efficiency cannot be overstated. With the global jewelry market expected to reach $480 billion by 2025, according to industry reports, the demand for advanced tools has surged. Among these tools, the 200w Jewelry Spot Welder stands out as a vital asset for craftsmen seeking to achieve flawless seams in their intricate creations.

This powerful welder not only enhances productivity but also ensures the durability of joints, making it a preferred choice for jewelers. As the leading manufacturer of laser systems, Maven Laser Automation Co., Ltd. has been at the forefront of providing high-quality automation solutions since 2008, helping artisans elevate their craft with cutting-edge technology. In this ultimate guide, we will explore essential tips and techniques to master the 200w Jewelry Spot Welder, ensuring perfect joints every time and maximizing your production potential.

This powerful welder not only enhances productivity but also ensures the durability of joints, making it a preferred choice for jewelers. As the leading manufacturer of laser systems, Maven Laser Automation Co., Ltd. has been at the forefront of providing high-quality automation solutions since 2008, helping artisans elevate their craft with cutting-edge technology. In this ultimate guide, we will explore essential tips and techniques to master the 200w Jewelry Spot Welder, ensuring perfect joints every time and maximizing your production potential.

Understanding the Basics of 200w Jewelry Spot Welders

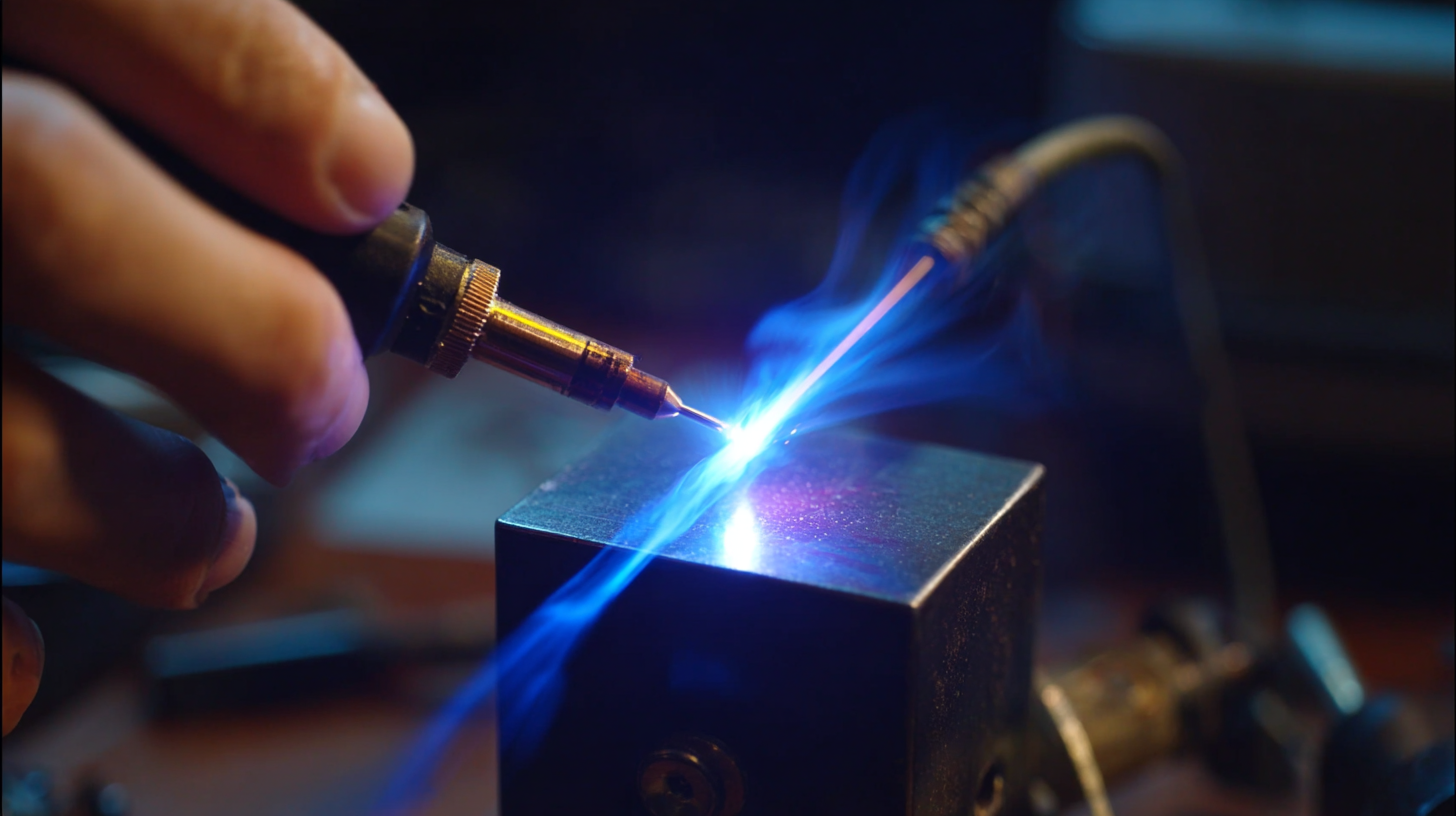

When it comes to jewelry making, precision is key, and a 200w jewelry spot welder is an essential tool for achieving perfect joints. Understanding the basics of this powerful device can significantly enhance your crafting skills. A 200w spot welder utilizes concentrated heat and pressure to fuse metal pieces together, allowing for clean, seamless joints that maintain the integrity of the material. This technology is particularly beneficial in creating delicate and intricate pieces that require a high level of finesse.

To get started with your 200w jewelry spot welder, it's important to familiarize yourself with its components. The main elements include the welding tip, power settings, and cooling system. Adjusting the power settings according to the thickness and type of metal you are working with can make a substantial difference in the quality of the weld. Additionally, mastering the technique of applying the right amount of pressure at the right moment will ensure optimal results. With practice, you will be able to create strong, aesthetically pleasing joints that elevate your jewelry designs to the next level.

Key Features and Specifications of a 200w Spot Welder

When exploring the intricate world of jewelry making, having the right tools is paramount, and the 200w spot welder stands out as an essential asset for jewelers. This powerful device typically operates at a peak power rating of 200 watts, allowing for the precise and strong welding needed for fine metals. A notable feature of the 200w spot welder is its adjustable pulse duration, which can drastically affect the quality of the joint. Industry reports indicate that optimal pulse settings can increase joint strength by up to 30%, making it a crucial factor for jewelers who prioritize durability.

Moreover, the 200w spot welder usually employs a user-friendly interface with digital controls for temperature and pulse time settings. This allows for accurate adjustments based on the specific materials being welded, be it gold, silver, or other alloys. According to a 2023 study published in the Journal of Materials Science, specialized spot welding techniques can improve metal fusion quality, enhancing aesthetics and reducing post-weld finishing work by nearly 25%. Understanding these key specifications and the application of this powerful tool can greatly impact the quality and efficiency of jewelry production.

Step-by-Step Guide to Setting Up Your Jewelry Spot Welder

Setting up your jewelry spot welder is crucial for achieving perfect joints in your creations. Whether you're a professional jeweler or a hobbyist, mastering your 200w jewelry spot welder can significantly enhance the quality of your work. According to industry reports, inadequate welding techniques can lead to a 20% increase in material waste, highlighting the importance of proper setup and operation. Begin by ensuring your workspace is organized and free from distractions. Familiarize yourself with the welding machine’s settings, focusing on power levels and welding times suitable for the materials you'll be working with.

Next, follow a systematic approach to set up your welder. Check all connections and ensure that your machine is calibrated according to the specific guidelines provided by the manufacturer. Understanding that different metals require different welding parameters can save time and prevent costly errors. For example, studies indicate that using the correct heat settings can improve joint strength by up to 30%, which is vital when working on intricate jewelry pieces. With the right setup, you’ll find that your spot welder not only provides seamless joints but also enhances your overall productivity in jewelry production.

Techniques for Achieving Strong and Precise Joints

Mastering the techniques of joint formation with a 200w jewelry spot welder can significantly impact the quality and durability of your jewelry creations. Achieving strong and precise joints not only enhances the aesthetic appeal but also ensures that pieces withstand the test of time. Recent studies emphasize the importance of proper joint design, showing that effective electrolocation methods can lead to improved accuracy in positioning and joint formation. For example, advancements in underwater bionic positioning systems highlight the potential of algorithmic approaches for long-range, high-precision localization, which parallels the need for precision in jewelry welding.

Furthermore, the complexities of adhesively bonded joints (ABJs) are analogous to the challenges faced in jewelry making. A review published indicates that the design and manufacturing of ABJs focus on optimizing strength and minimizing failure rates—principles that are equally applicable to the jewelry industry. Techniques that incorporate specialized welding methods have been shown to improve the integrity of the joint, ensuring robust connections that can support intricate designs. By leveraging insights from these fields, jewelers can refine their welding techniques to produce flawless joints that enhance both functionality and beauty.

Ultimate Guide to Mastering the 200w Jewelry Spot Welder for Perfect Joints

| Technique | Description | Strength of Joint | Recommended Settings | Common Uses |

|---|---|---|---|---|

| Tack Welding | Quickly joining pieces to hold them in place before final welding. | Moderate | Power: 50%, Time: 0.1s | Setting up parts for assembly |

| Full Weld | Comprehensive welding of two surfaces for durability. | High | Power: 65%, Time: 0.5s | Finalizing jewelry pieces |

| Spot Welding | Localized welding at specific points for precision. | Very High | Power: 70%, Time: 0.3s | Joining delicate parts |

| Seam Welding | Continuous welding along the seam for a smooth joint. | High | Power: 55%, Time: 0.4s | Creating smooth edges |

Common Mistakes to Avoid When Using a Spot Welder

When using a spot welder, avoiding common mistakes can significantly enhance your welding experience and outcomes. One frequent error is neglecting the importance of proper machine settings. Ensure that the amperage and duration of the weld are appropriately calibrated for the materials you are working with. Incorrect settings can lead to weak joints or excessive heat, damaging the components. Always refer to manufacturer guidelines for optimal configuration.

Another pitfall is inadequate preparation of the surfaces to be welded. Cleanliness is crucial; any contaminants such as oils, dust, or oxidation can adversely affect the weld quality. Prioritize cleaning the surface thoroughly and verify alignment before initiating the weld. This attention to detail can prevent common defects, such as misalignment or underfill, that compromise the joint’s integrity.

Lastly, it's vital to monitor the welding process closely. Overlooking changes in the welding gun's performance can lead to faults that disrupt production. Implementing a routine inspection, like those seen in automotive manufacturing, can aid in fault prediction and ensure smoother operations. By focusing on these areas, you can master your spot welding technique and achieve consistent, high-quality results.

Maintenance Tips for Prolonging the Life of Your Spot Welder

Maintaining your 200w jewelry spot welder is crucial not only for ensuring its longevity but also for achieving perfect joints in your projects. According to a report by Industrial Welding Technology, regular maintenance can extend the lifespan of welding equipment by up to 30%. This includes routine checks on the power supply, electrode condition, and cooling systems. Keeping the welder clean from debris and ensuring that the contact points are free from oxidation can drastically improve efficiency and weld quality.

Additionally, manufacturers recommend implementing a maintenance schedule that includes periodic inspections and part replacements. This proactive approach can prevent unexpected failures and costly downtime. A study by the Welding Research Institute indicated that poorly maintained equipment could lead to an increase in defects by as much as 20%, significantly impacting project timelines and quality. For jewelers relying on spot welders, even minor maintenance efforts can yield substantial results, enhancing both operational reliability and the visual appeal of the final product.

FAQS

: Setting up a jewelry spot welder is crucial for achieving perfect joints in your creations, enhancing the quality of your work and reducing material waste.

Focus on the welding machine’s settings, particularly power levels and welding times that are suitable for the materials you will be using.

Check all connections and refer to the manufacturer’s guidelines for calibration to ensure your machine is set up correctly for the specific metals you are working with.

Using the correct heat settings can improve joint strength by up to 30%, which is vital for creating intricate jewelry pieces.

Mastering joint formation techniques, optimizing joint design, and leveraging algorithmic approaches for precision can significantly improve the quality and durability of your jewelry.

Proper surface preparation is crucial as contaminants like oils and dust can adversely affect weld quality, leading to defects and compromised joint integrity.

Common mistakes include neglecting proper machine settings, inadequate surface preparation, and overlooking performance changes during the welding process.

Implementing a routine inspection can help predict faults and ensure smoother operations, leading to consistent high-quality results.

Insights from advancements in electrical techniques, such as effective electrolocation methods, can inform improvements in positioning and joint formation in jewelry welding.

Incorrect machine settings can lead to weak joints or excessive heat, potentially damaging the components and diminishing the overall quality of the weld.

Conclusion

In the "Ultimate Guide to Mastering the 200w Jewelry Spot Welder for Perfect Joints," readers will embark on a comprehensive journey through the intricacies of using this essential tool for jewelry making. The guide begins with a fundamental understanding of the 200w Jewelry Spot Welder, highlighting its key features and specifications that set it apart in the market. It offers a thorough step-by-step setup process, ensuring that users can achieve precision and strength in their joints.

Moreover, the guide delves into effective techniques for creating robust connections, while addressing common pitfalls to avoid during operation. To ensure longevity, it also provides essential maintenance tips for the 200w Jewelry Spot Welder, promoting optimal performance over time. This resource is invaluable for both beginners and seasoned artisans looking to enhance their craft with reliable automation solutions from leaders like Maven Laser Automation Co., Ltd.

Related Posts

-

Discover the Finest Laser Cleaner: Premium Quality from China's Leading Manufacturing Factory

-

Unleashing Global Confidence: Premium Laser Markers from China's Leading Factory

-

A Comprehensive Comparison of 500W Pulsed Laser Cleaner: Performance, Efficiency, and Cost

-

Unmatched Quality in Laser Cleaning for Wood Trim from China's Leading Manufacturer

-

Comprehensive Solutions for Efficient Rust Removal with the Best 3000W 4-In-1 Laser Cleaning Machine

-

7 Reasons Why Laser Cleaning Machines are Essential for Wood and Steel Industries

Blog Tags:

Olivia

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top