Unlock Your Creativity with a Mini Laser Cutting Machine for Impressive DIY Projects

Table of Contents

- Explore the Basics of Mini Laser Cutting Machines for DIY Enthusiasts

- Top 5 Creative Projects to Try with Your Mini Laser Cutter

- Essential Tips for Getting Started with Laser Cutting at Home

- Safety Precautions to Consider When Using a Mini Laser Cutter

- Materials You Can Use for Your DIY Laser Cutting Projects

- How to Enhance Your Laser Cutting Skills with Online Resources and Communities

- FAQS

- Conclusion

- Related Posts

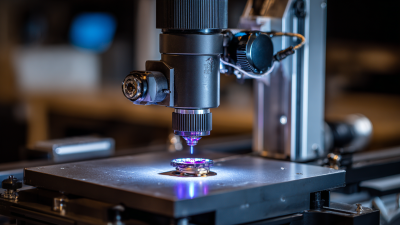

Unlocking your creative potential has never been easier with the advent of the Mini Laser Cutting Machine, a game-changer for DIY enthusiasts and professional makers alike. This compact yet powerful tool empowers users to transform their ideas into reality through precise cutting and engraving. Whether you're crafting intricate designs for home décor, personalizing gifts, or exploring new artistic avenues, the Mini Laser Cutting Machine offers unmatched versatility and precision. At Maven Laser Automation Co., Ltd., a premier manufacturer of laser systems and automation solutions since 2008, we are dedicated to providing innovative tools that enhance your creative projects. Located in Shenzhen, China, Maven Laser's commitment to quality and cutting-edge technology ensures that you can bring your imaginative concepts to life with ease and efficiency. Embrace the world of DIY projects and let your creativity flow with the remarkable capabilities of a Mini Laser Cutting Machine.

Explore the Basics of Mini Laser Cutting Machines for DIY Enthusiasts

Mini laser cutting machines have become essential tools for DIY enthusiasts looking to enhance their creative projects. These compact devices utilize high-powered lasers to precisely cut and engrave various materials such as wood, acrylic, and fabric. The ease of use and versatility of mini laser cutters make them perfect for both beginner and experienced crafters. Understanding the basics of how these machines operate can empower users to explore their artistic potential and transform ideas into tangible creations.

Mini laser cutting machines have become essential tools for DIY enthusiasts looking to enhance their creative projects. These compact devices utilize high-powered lasers to precisely cut and engrave various materials such as wood, acrylic, and fabric. The ease of use and versatility of mini laser cutters make them perfect for both beginner and experienced crafters. Understanding the basics of how these machines operate can empower users to explore their artistic potential and transform ideas into tangible creations.

Before diving into the world of mini laser cutting, it’s crucial to familiarize yourself with key components such as laser safety, material compatibility, and software requirements. Safety measures are paramount, as working with lasers can pose risks if not handled correctly. Additionally, selecting the right materials is essential, as some may produce hazardous fumes when cut. Lastly, most mini laser machines use specific design software that allows users to create intricate patterns and designs before cutting, ensuring that each project is unique and tailored to individual tastes. By grasping these fundamentals, DIY enthusiasts can fully unlock their creativity and bring impressive projects to life.

Top 5 Creative Projects to Try with Your Mini Laser Cutter

With the rise of mini laser cutting machines, the possibilities for DIY projects are expanding rapidly. These compact tools empower creators to delve into a myriad of artistic endeavors, producing intricate designs with precision that was once only possible with larger, industrial-grade equipment. Whether you're a hobbyist looking to craft personalized gifts or an entrepreneur aiming to start a small business, owning a mini laser cutter can significantly unlock your creative potential.

Here are five inspiring projects to try with your mini laser cutter. First, consider creating custom jewelry pieces that reflect your unique style—think intricate earrings or personalized pendants. Next, design unique home decor items, such as laser-cut wall art or decorative coasters, to add a personal touch to your living space. Another engaging project is crafting personalized stationery, where you can make custom invitations or greeting cards. Consider also creating customized items for special occasions, like laser-engraved gifts for weddings or birthdays. Lastly, try your hand at DIY models or prototypes, which allow you to bring your inventive ideas to life seamlessly. Each of these projects not only showcases the versatility of a mini laser cutter but also inspires new ways to express creativity through technology.

Essential Tips for Getting Started with Laser Cutting at Home

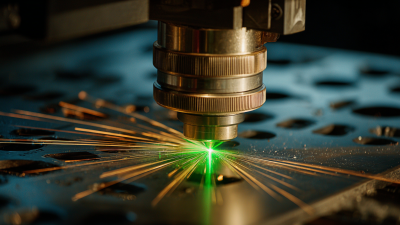

Laser cutting has emerged as a transformative technology for DIY enthusiasts, offering precision and versatility for various projects. According to a recent report from the Laser Institute of America, the global laser cutting market is projected to reach $5.6 billion by 2027, illustrating a growing demand for laser cutting technology in both industrial and consumer applications. This expansion indicates that more individuals are engaging in creative pursuits at home using tools like mini laser cutting machines, which facilitate intricate designs and streamlined processes.

When getting started with laser cutting at home, it's essential to understand the basics of your machine. Familiarize yourself with software options such as Adobe Illustrator or CorelDRAW, which are widely used for designing laser-cut files. Additionally, choosing the right materials is crucial. Popular choices include acrylic and plywood, due to their suitability for laser cutting and availability. According to a study by the Maker Media Group, 65% of makers reported that ease of use and material compatibility significantly influenced their choice of machinery. By taking these steps, you can unlock your creativity and embark on impressive DIY projects that showcase your unique style.

Safety Precautions to Consider When Using a Mini Laser Cutter

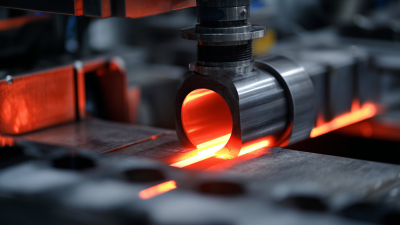

When delving into the world of mini laser cutting machines, it's crucial to prioritize safety. These powerful tools can produce intricate designs but can also pose risks if not handled correctly. Always begin by wearing appropriate safety gear, such as goggles designed for laser operations, to protect your eyes from harmful beams and reflected light. This simple step is vital for preventing potential injuries.

Additionally, ensure your workspace is well-ventilated. Laser cutting can produce fumes, especially when working with materials like wood or plastics. Consider using a fume extractor to minimize inhalation risks. Furthermore, keep a fire extinguisher nearby, as the heat generated during cutting can ignite flammable materials. Understanding your machine's operational limits and following the manufacturer's guidelines will further enhance your safety.

**Tips:** Before starting your project, familiarize yourself with your mini laser cutter's features. Spend time understanding the settings related to speed, power, and material compatibility to achieve the best results. Lastly, practice on scrap materials to become comfortable with your machine's capabilities and ensure precise cutting without unnecessary risks.

Unlock Your Creativity with a Mini Laser Cutting Machine for Impressive DIY Projects

| Project Type | Material | Estimated Time | Safety Precautions |

|---|---|---|---|

| Custom Coasters | Cork | 1-2 hours | Wear safety goggles, keep workspace ventilated |

| Personalized Keychains | Acrylic | 30 minutes | Avoid inhaling smoke, use appropriate settings |

| Wall Art | Wood | 2-3 hours | Ensure proper laser settings, keep flammable materials away |

| Greeting Cards | Cardstock | 1 hour | Handle with care, check machinery regularly |

Materials You Can Use for Your DIY Laser Cutting Projects

Unlocking your creativity has never been easier with a mini laser cutting machine, especially when you consider the wide range of materials you can work with for your DIY projects. From wood and acrylic to leather and paper, each material offers unique textures and finishes that can elevate your creations. For instance, intricate designs can be etched onto wood, giving your projects a warm, rustic feel, while acrylic can provide vibrant colors and sharp finishes that catch the eye. Leather is another popular option, perfect for creating personalized accessories such as wallets or keychains.

At Maven Laser Automation Co., Ltd., we understand the potential that these materials hold in transforming everyday ideas into impressive projects. As a leading manufacturer of laser systems and professional automation solutions, our expertise since 2008 positions us as a reliable partner for hobbyists and professionals alike. Our mini laser cutting machines are designed with precision and ease of use in mind, allowing you to unlock your artistic potential and bring your unique visions to life, regardless of your skill level.

Whether you’re crafting home decor or custom gifts, the possibilities are endless with the right materials and tools at your fingertips.

How to Enhance Your Laser Cutting Skills with Online Resources and Communities

Enhancing your laser cutting skills can be an exhilarating journey, and online resources are a treasure trove for DIY enthusiasts. Websites like YouTube offer countless tutorials from experienced makers, breaking down complex techniques into manageable steps. These visual guides allow you to see the laser cutting process in action, helping you understand the nuances of different materials and settings. Furthermore, specialized forums and blogs provide in-depth articles, project ideas, and troubleshooting tips that can significantly elevate your craft.

Joining online communities is another effective way to boost your skills. Platforms such as Reddit or dedicated Facebook groups connect you with fellow laser cutting aficionados. Here, you can share your projects, receive feedback, and gain inspiration from others’ work. These communities often organize challenges or collaborative projects, fostering a supportive environment for both beginners and seasoned makers. Engaging with others not only enhances your technical abilities but also cultivates a sense of belonging as you explore the endless possibilities of laser cutting.

Monthly Usage of Laser Cutting Machines for DIY Projects

This chart illustrates the monthly usage frequency of laser cutting machines by DIY enthusiasts, highlighting how online resources and communities support skill enhancement.

FAQS

: Mini laser cutting machines are used for various DIY projects including cutting and engraving materials such as wood, acrylic, leather, and fabric, allowing users to create intricate designs and personalized items.

Key safety precautions include wearing laser safety goggles, ensuring a well-ventilated workspace, using a fume extractor, keeping a fire extinguisher nearby, and understanding the machine's operational limits.

Mini laser cutting machines can work with a variety of materials, including wood, acrylic, leather, paper, and fabric, each offering unique textures and finishes for creative projects.

Beginners can practice on scrap materials to gain familiarity with the machine's settings, including speed and power, to ensure precise cutting and avoid unnecessary risks.

Most mini laser cutting machines require specific design software to create custom patterns and designs before cutting, allowing users to tailor projects to their preferences.

Yes, laser cutting can produce fumes, especially with materials like wood or plastics, so it's important to work in a well-ventilated area and consider using a fume extractor to minimize inhalation risks.

With a mini laser cutter, you can create a wide range of projects including home decor, personalized gifts, accessories, and intricate craft items, limited only by your creativity and the materials used.

Understanding the operational limits of your laser cutter is vital for safe use and achieving the best results, as it helps to avoid overloading the machine and potential accidents.

Before starting a project, familiarize yourself with your mini laser cutter’s features, settings, and material compatibility, and practice cutting on scrap materials to ensure comfort and precision.

Conclusion

Unlocking creativity has never been easier with a Mini Laser Cutting Machine. This versatile tool empowers DIY enthusiasts to explore a range of projects, from custom designs to intricate art pieces. The article delves into the basics of mini laser cutting machines, offering a thorough understanding of their capabilities and potential applications. It highlights five creative projects that can inspire users to get started, along with essential tips for navigating the initial learning curve.

Furthermore, safety precautions are emphasized to ensure a secure working environment while using the Mini Laser Cutter. A guide on suitable materials aids users in selecting the right options for their projects, and resources for enhancing laser cutting skills, including online communities, are shared. Maven Laser Automation Co., Ltd., with its expertise in laser systems and automation, stands ready to support enthusiasts in their DIY journey, harnessing the power of mini laser cutting technology to transform their creative visions into reality.

Related Posts

-

Understanding the Advantages of Fiber Laser Welding Machines for Modern Manufacturing

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

How to Effectively Use Portable 1000w Laser Cleaner for Industrial Applications

-

Revolutionary Applications of the 200W Laser Cleaner for Wood Restoration and Maintenance

-

7 Essential Tips for Using the Aser Cleaning Machine to Remove Paint from Wood

-

What is the Importance of Industrial Laser Cleaning Machine in Modern Manufacturing

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top