As an advanced processing tool, laser is playing an increasingly important role in the field of industrial welding. Although traditional laser welding technology can control these defects to a certain extent, its effect is often limited by fixed welding parameters and processes. In recent years, the appearance of laser swing welding technology provides a new solution for the control of welding defects. By introducing the swing of the laser beam during the welding process, the technology can significantly improve the dynamic characteristics of the weld pool, thereby optimizing the welding quality. Laser swing welding technology is mainly based on the precise control of the laser beam and swing technology to achieve efficient and high-quality welding.

Improve appearance:

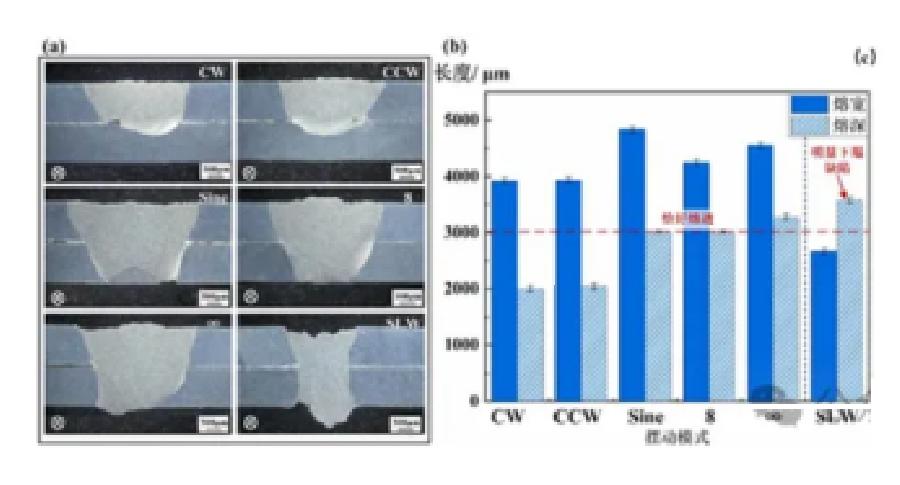

During the welding process, the laser beam is swung quickly and precisely to cover the entire welding area. When the beam moves along the direction of the weld, it oscillates in various forms, such as circle, figure 8 and helix. Chen et al. used swing laser to weld dissimilar aluminum alloys, and compared with no swing laser welding, the front and back weld morphology of swing laser welding was significantly improved. In addition, transverse swing laser welding is used to increase the clearance adaptability of the groove. On some conductive connection workpieces, it is necessary to expand the overcurrent area, it is also necessary to expand the metallic connection surface, and it is also necessary to swing the laser welding to make the metallic connection surface become “U”.

1. (a) and (b) statistics of weld cross section morphology and weld size under different swing modes; (c) Forming of the upper surface of the weld under different swing modes.

Improve poor side wall fusion:

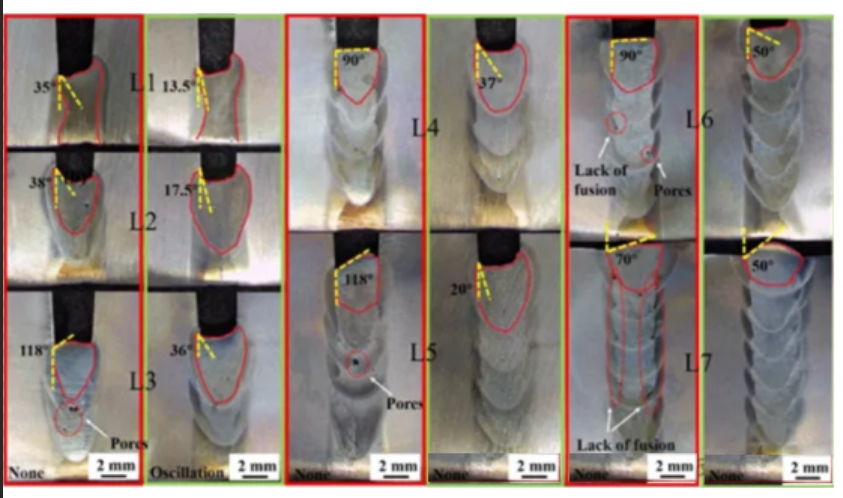

The defect of side wall non-fusion is easy to occur in the traditional narrow gap laser welding of medium thick plate, which is caused by the uneven distribution of laser energy in the mouth, the heat input in the center of the groove is large, and the heat input in the side wall of the groove is small, which can not form a good combination. The key measure to solve the unfused side wall defect is to increase the heat input to the side wall. In the process of laser welding, a more reasonable energy distribution of the laser beam on the workpiece surface can be realized through the beam swing. When the width of the groove changes, the amplitude of the beam swing is adjusted to match the width of the groove, so as to form an effective heat input to the side wall.

2. Macroscopic image of the weld from the first layer (L1) to the seventh layer (L7) for laser welding with or without oscillation.

Reduce porosity defects:

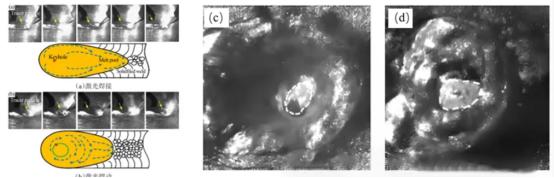

The inhibition mechanism of laser swing on welding pores can be attributed to improving the stability of small holes and improving the fluidity of liquid metal. Figure 3 shows the flow behavior of the molten pool shown by the tracer particles during the welding process. The wiggling of the light beam causes the small hole to form a high-frequency and high-speed rotational stirring motion, which promotes the bubble overflow and has a “trapping” effect on the solidified pores. At the same time, the wiggling of the light beam increases the area of the small hole and reduces the probability of its instability collapse to form bubbles.

3. (a) and (b) trajectories of tracer particles during welding; Keyhole opening area: (c) no swinging laser (d) swinging laser.

Reduce crack defects:

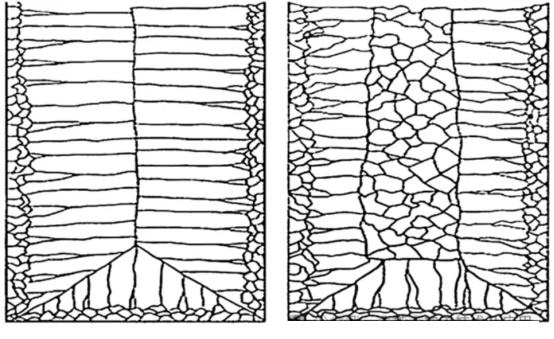

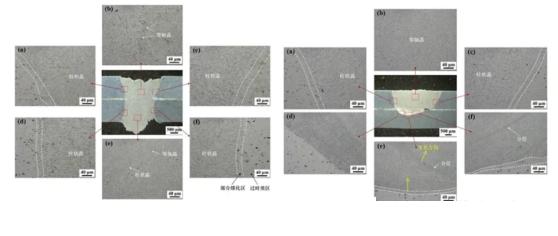

Thermal crack is a kind of defect formed in the welding process due to the interaction of internal stress and metallurgical factors, which is often found in the heat affected zone (HAZ) of welding. The formation of such cracks is related to the vulnerability of the material at high temperatures, welding stress and the chemical composition of the material. Traditional laser welding technology may produce thermal cracks in the welding process, mainly for the following reasons: First, due to the high energy input of laser welding, resulting in rapid heating and cooling of the welding area, resulting in a large thermal gradient and thermal stress; Secondly, the metallurgical reaction in the welding process may lead to the segregation of impurity elements with low melting point, forming a brittle phase and increasing the sensitivity of cracks. Finally, the rapid solidification of the material may lead to the heterogeneity of the microstructure, and the growth direction of the columnar crystals is from the molten pool to the center, as shown in Figure 4. In this case, the sensitivity to cracking is significantly increased.

4. Laser welding solidification mode (a) conventional laser welding (b) swing laser welding.

The oscillating laser welding technology can effectively reduce or eliminate the occurrence of hot cracks by introducing the oscillating laser beam. During the oscillating laser welding process, the periodic oscillation of the laser beam can promote the metal flow in the molten pool, thus improving the uniformity of the microstructure, and the grain grows coaxial in the center of the molten pool, as shown in Figure 5. These coaxial grains act as a protective barrier to prevent crack propagation and act as a thermal insulation layer to prevent further crack propagation. At the same time, the oscillating laser helps reduce brittle phase formation due to component segregation, reducing the risk of thermal cracking.

5. (A) solidification microstructure characteristics of conventional laser welding welds (B) solidification microstructure characteristics of laser swing welds (CCW).

Compared with laser self-fusion welding, swing laser welding technology has been recognized as an effective way to reduce the tendency of porosity and improve the defects such as non-fusion of side walls. Due to the stirring effect of the beam on the molten pool, it has significant advantages in improving the gap fit, improving the microstructure uniformity and refining the grain. The application of laser swing welding technology can make laser welding more widely used, and laser efficient precision welding can be achieved for larger workpieces and wider welds, that is, the basic process and assembly accuracy of the product are relaxed.

Post time: Feb-21-2025