【Technology Frontier】Unveiling Platform Welding Machines: The Intelligent Choice for Precision Welding

Machine Introduction: Two Core Types, Each Excelling in Its Field

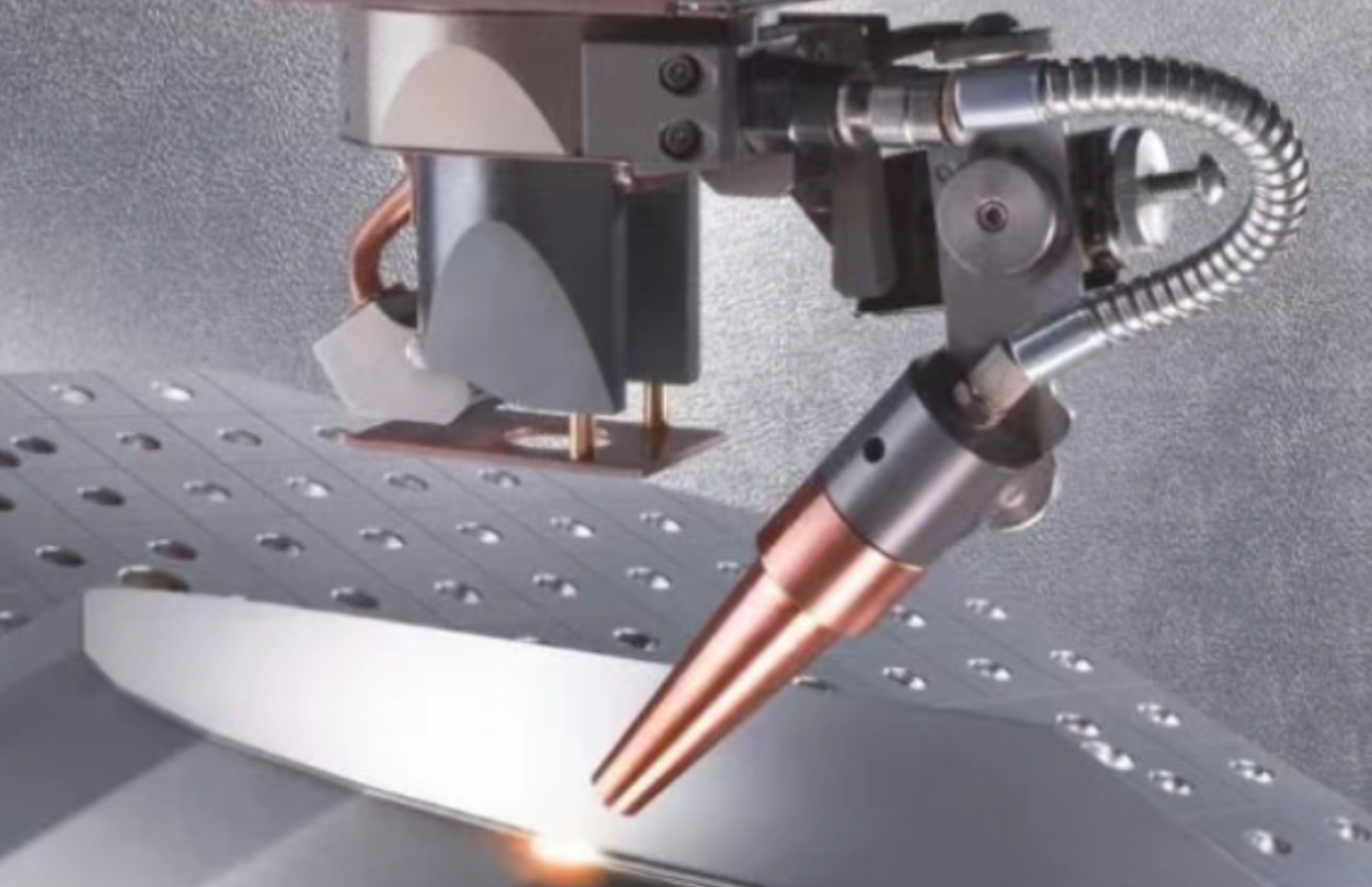

As a high-tech welding equipment, the platform welding machine, with its outstanding performance and flexibility, is mainly divided into two categories: cantilever welding machines and galvo welding machines. Its core components include key parts such as lasers, welding heads, cooling systems, motion control systems, software control systems, and camera display systems. These precision components work in synergy, enabling the platform welding machine to easily handle the welding needs of various materials—including aluminum, carbon steel, stainless steel, copper, and alloys. Whether it is single-point welding, linear welding, arc welding, or even more complex welding trajectories, it can accomplish the task with ease.

What is even more impressive is that by matching with jigs and fixtures, the platform welding machine can flexibly fix workpieces. Even parts of different shapes and sizes can be welded with high quality under precise control, demonstrating its high adaptability and flexibility.

Application Scope: Cross-industry Integration, Ubiquitous Presence

The application scope of platform welding machines is surprisingly wide. From precision electronic components to large automotive parts, from small pipe fittings to complex door and window accessories, and even the delicate welding of craft gifts, platform welding machines can handle them all.

In the hardware industry, it improves production efficiency;

In the pipe fitting industry, it ensures welding quality;

In the electronics industry, it guarantees the precision and reliability of products with its tiny weld spots and small heat-affected zones.

Optional Equipment: Customized Upgrades, Endless Possibilities

To meet the welding needs of different industries and workpieces, platform welding machines offer a rich range of optional equipment. From oscillating welding heads and galvo welding heads to visual positioning systems and rotary platforms, as well as wire feeding systems, unidirectional/bidirectional rotary welding heads, tooling jigs, and CCD observation systems, these optional devices allow the platform welding machine to achieve further customized upgrades. They meet customers’ specific needs and enable the optimization and innovation of welding processes.

Machine Features: High Efficiency, Energy Saving, Leading the Future with Intelligence

The platform welding machine not only leads the trend in technology but also embodies the perfect combination of humanization and intelligence in its design concept.

The machine adopts an ergonomic design with a user-friendly operation interface, providing operators with a comfortable working experience;

It is easy and quick to install, and the software operation is simple to learn—even novices can master it quickly.

More importantly, the platform welding machine features fast welding motion speed, high precision, and high efficiency, which greatly shortens the production cycle and reduces costs. Its small weld spots and small heat-affected zones minimize workpiece deformation, resulting in flat and aesthetically pleasing weld seams. After welding, little to no post-processing is required to achieve the ideal welding effect.

In addition, the laser efficiency is as high as over 55%, the overall machine energy consumption is low, and the optical components have a long service life with almost no maintenance needs. The built-in cooling system realizes circulating water cooling without the need for an external cold source. These features together form a solid foundation for the platform welding machine’s high efficiency, energy saving, stability, and reliability.

As an outstanding representative of modern precision welding technology, the platform welding machine is leading the manufacturing industry toward a path of higher quality and higher efficiency with its unparalleled flexibility, efficiency, and precision. In the future, with the continuous advancement of technology and the expansion of application fields, the platform welding machine will surely shine more brilliantly and bring more surprises and possibilities to our lives.