3W 5W High-Speed Serial Number Marking Automotive Parts for Plastic & Glass Jewelry Laser Marking Machine

Key Features

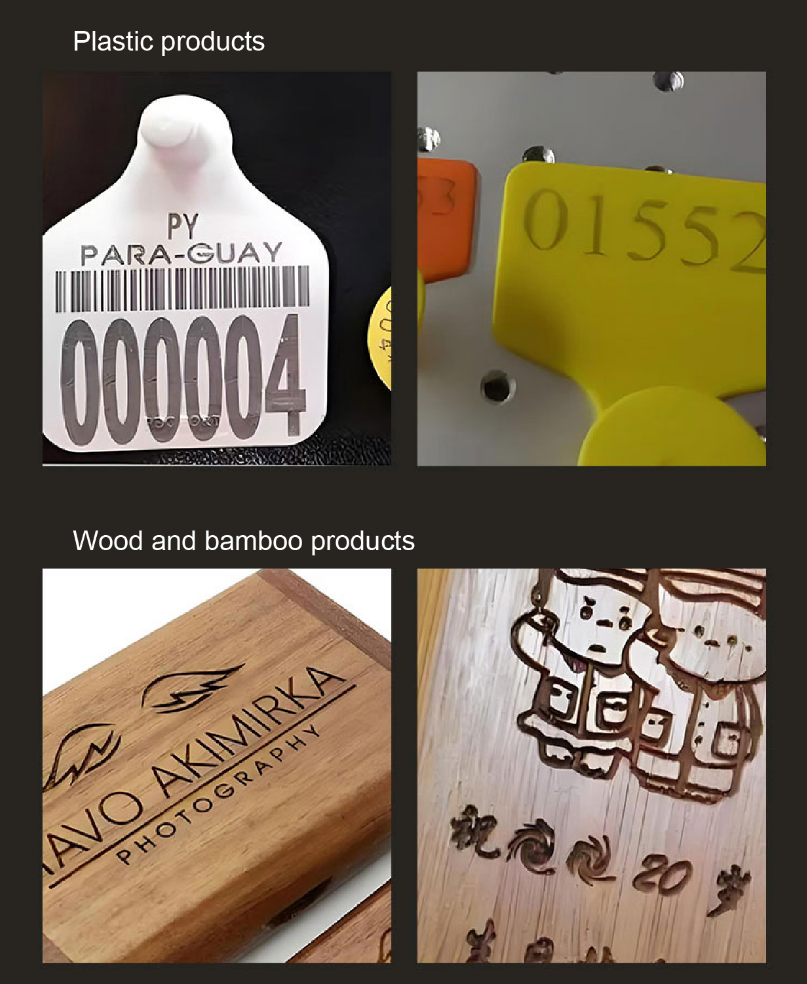

- Wide Application Range: With different types of laser generators, it can process almost all kinds of mechanical parts from metals to non-metals.

- Non-contact Processing: No mechanical collision or large-scale thermal stress occurs during the marking process, which will not reduce the service life of workpieces nor cause processing errors due to tool wear.

- High Processing Precision: The laser beam has excellent focusing performance and can form an extremely fine beam, enabling the completion of processes that cannot be achieved by conventional methods, such as marking and identification of electronic component labels, barcodes, and QR codes.

- Low Cost: The "tool" used is the focused laser beam, eliminating the need for additional equipment and materials. As long as the laser operates normally, it can work continuously for a long time.

- High Processing Efficiency: Laser marking features fast processing speed, and can usually complete the marking of any complex graphics within seconds.

- High Controllability: The laser marking system is automatically controlled by an industrial computer, requiring no manual intervention during production. Various design files can be created through laser marking software and accurately reproduced on the workpiece surface.

Application Fields

Laser marking machines are widely used in numerous fields, including electronic components, integrated circuits, electrical appliances, mobile communications, hardware products, tool accessories, precision instruments, glasses and clocks, jewelry and ornaments, auto parts, plastic keys, building materials, and PVC pipes.

Write your message here and send it to us