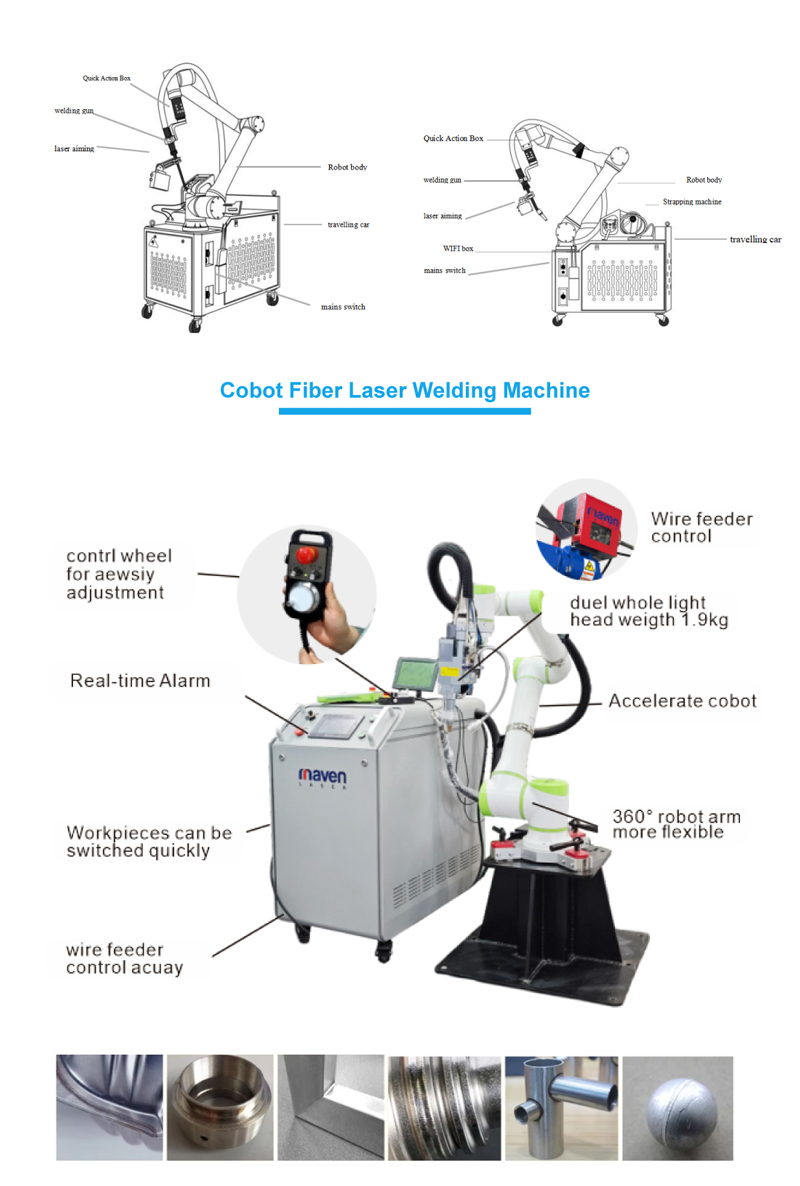

Automatic High Precision for Jewelry & Hardware Manufacturing Cobot Laser Welding Machine

Key Features

- Easy Operation

No professional welding or programming knowledge is required. Users can program the device via drag-and-drop operation, significantly lowering the operational threshold. - High Precision

The laser beam features a small focused spot, enabling micron-level precision welding. Equipped with a high-accuracy collaborative robot for positioning, it ensures superior weld joint quality and strength while minimizing welding deformation and defects. - Exceptional Flexibility

The collaborative robot boasts multiple degrees of freedom, allowing flexible operation even in confined spaces. It supports rapid deployment, adapts to various non-standard designs and small-batch production needs, and enables quick switching between different welding tasks. - Enhanced Safety

Integrated with safety functions such as collision detection, the collaborative robot can work collaboratively with human operators, effectively reducing safety risks. - Superior Weld Seam Quality

The welding head is typically equipped with a spot oscillation function, resulting in uniform, dense, and aesthetically pleasing weld seams with minimal deformation.

Application Fields

- Automotive Manufacturing

Ideal for welding auto bodies and components, including seamless splicing of critical parts such as roof panels, side panels, and door frames. It is also applicable to welding transmission gears, drive shafts, battery modules, and other components, improving welding precision and production efficiency. - Aerospace

Capable of welding high-temperature and high-pressure components (e.g., aero-engine blades and combustion chambers) and lightweight structural parts (e.g., aircraft fuselages and wings). It is also suitable for micro-welding of precision electronic components in satellite assemblies. - Electronics & Electrical Appliances

Suitable for welding metal casings of mobile phones, computers, and other consumer electronics, as well as micro-components such as sensors and battery tabs. It meets the stringent requirements of miniaturization and high-precision welding in the industry. - Medical Devices

Enables high-precision welding of surgical instruments (e.g., scalpels, forceps, and endoscopes) and implants (e.g., artificial joints and cardiac stents). It complies with the strict industry standards for medical devices, including pollution-free processing, crack-free welds, and excellent biocompatibility.

- Shipbuilding

Performs flexible welding operations in the complex structural environment of ship hulls. It is suitable for welding high-strength steel, aluminum alloy, and other materials, ensuring both welding quality and efficiency.

Write your message here and send it to us