What are the Benefits of Using a Laser Cleaner Machine?

Table of Contents

- Overview of Laser Cleaner Machines

- How Laser Cleaning Works: The Science Behind It

- Advantages of Laser Cleaning Over Traditional Methods

- Environmental Benefits of Using Laser Cleaners

- Applications of Laser Cleaning in Various Industries

- Cost-Effectiveness and Efficiency of Laser Cleaning

- Safety Considerations and Best Practices in Laser Cleaning

- Maximizing Efficiency: Insights from Industry Reports on Fiber Laser Cleaning Machines for Optimal Metal Paint and Oil Removal Solutions

- FAQS

- Conclusion

- Related Posts

The Laser Cleaner Machine really is changing the game in the cleaning world. It’s this pretty cool tech that uses lasers to get rid of all kinds of gunk—like rust, paint, dirt—without messing up the surface underneath. Honestly, it’s a lot better than the old-school methods because it cuts down on waste and is way gentler on the environment.

More and more companies are jumping on board with this thing. For example, industries can clean their equipment with incredible precision—no more guesswork. That said, if you're running a small business, the upfront cost can be a bit of a sticker shock. So, it’s definitely worth sitting down and really thinking through whether the benefits outweigh the costs.

A lot of users say it helps them get things done faster and with less effort. It’s a real time-saver and can cut down on labor hours. But here’s the thing—you don’t just plug it in and suddenly become a pro. It takes some training and practice to get the hang of it. It’s not exactly a magic fix you can master overnight, so weighing the pros and cons carefully is key.

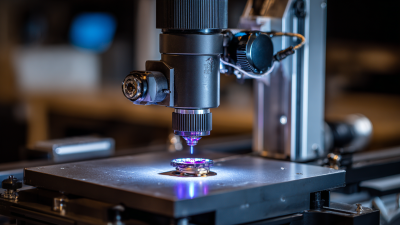

Overview of Laser Cleaner Machines

Laser cleaner machines have gained popularity across various industries. They serve as effective tools for cleaning surfaces and removing contaminants. According to a report by MarketsandMarkets, the laser cleaning market is projected to reach $1.5 billion by 2026, reflecting a growing acceptance among manufacturers.

These machines utilize high-intensity lasers to eliminate rust, paint, and grime. Unlike traditional methods, they produce minimal waste and require less water. The lack of chemical agents makes them environmentally friendly. However, the initial investment can be substantial. Not all businesses may afford the upfront costs, which can hinder widespread adoption.

While laser cleaning offers benefits, there are challenges. The technology is still relatively new. Moreover, operators need proper training to use these machines safely. Misuse can lead to surface damage or safety hazards. With advancements in technology, laser cleaner machines will likely see improved efficiency and accessibility in the future. Companies must weigh the benefits against potential risks.

What are the Benefits of Using a Laser Cleaner Machine?

| Benefit | Description | Application Areas |

|---|---|---|

| Environmentally Friendly | Uses no chemicals or abrasive materials, reducing environmental impact. | Manufacturing, Automotive, Conservation |

| High Precision | Allows for detailed and intricate cleaning without damaging surfaces. | Electronics, Aerospace, Art Restoration |

| Cost-Effective | Reduces labor costs and the need for consumables, leading to lower overall expenses. | Construction, Shipbuilding, Maintenance |

| Versatile Usage | Effective on a variety of materials including metal, wood, and plastics. | Industrial Cleaning, Restoration, Renovation |

| Safety | Reduces risks associated with traditional cleaning methods such as exposure to harmful substances. | Manufacturing, Food Processing, Healthcare |

How Laser Cleaning Works: The Science Behind It

Laser cleaning technology offers a unique approach to surface cleaning. It utilizes high-intensity laser beams to remove contaminants. This process can effectively eliminate rust, paint, or grime without damaging the underlying material. The science behind it is quite fascinating. When the laser hits the surface, it interacts at a molecular level, causing dirt and unwanted layers to evaporate or be blown away.

Tip: Always test the laser on a small area first. This way, you can observe how the material reacts. Different surfaces may require different settings. Adjusting the power and pulse duration is crucial for optimal results.

The efficiency of laser cleaning depends on several factors. The distance, focus, and speed of the laser can impact its effectiveness. However, sometimes operators may overlook these elements, leading to subpar results. Finding the right balance can take practice and experimentation. Being attentive to how the laser interacts with the material is essential.

Tip: Keep the laser lens clean. A dirty lens can absorb energy and affect performance. Regular maintenance can dramatically improve cleaning results. Small changes often make a significant difference in precision and outcome.

Advantages of Laser Cleaning Over Traditional Methods

Laser cleaning technology has gained significant traction in recent years. It offers unique advantages compared to traditional methods like sandblasting or chemical cleaning. For instance, the precision of laser cleaning reduces the risk of damaging the underlying material. A recent industry report highlights that laser cleaning can achieve up to 90% efficiency in surface preparation, an impressive contrast to traditional methods that often hover around 60%. This efficiency is crucial for industries where surface integrity matters deeply.

Moreover, laser cleaning is more environmentally friendly. It eliminates the need for harsh chemicals, which can be harmful to both operators and the environment. According to environmental studies, traditional methods can release significant pollutants. Data shows that switching to laser technology can reduce hazardous waste generation by more than 80%. This shift not only benefits the environment but also reduces long-term disposal costs for businesses.

Despite these advantages, some challenges remain. The initial investment for laser cleaning machines can be considerable. There is also a learning curve associated with operating this advanced technology efficiently. Companies might struggle with training their workforce, or they may find it hard to justify the upfront costs in certain scenarios. Balancing these factors is critical for companies looking to modernize their cleaning processes.

Environmental Benefits of Using Laser Cleaners

Laser cleaner machines have gained attention for their environmental benefits. They use focused laser beams to remove contaminants without harmful chemicals. This makes them a safer option for cleaning various surfaces. By minimizing the use of solvents, these machines reduce hazardous waste. Less chemical runoff means fewer pollutants enter the water supply.

Moreover, laser cleaning is efficient. It often requires less energy than traditional methods. Although initial setup can be costly, the long-term savings on materials can be significant. Users should consider the learning curve involved. Operating the machine might take time to master. While it's effective, improper use may lead to surface damage or incomplete cleaning.

Another point to consider is waste generation. While lasers create less hazardous waste, they may still generate dust or particles. Effective vacuum systems are vital to capture these by-products. Users have to think about their cleaning processes. Is it truly the green solution they hoped for? Evaluating efficiency and waste is crucial.

Applications of Laser Cleaning in Various Industries

Laser cleaning technology has found valuable applications across various industries. It uses focused laser beams to remove contaminants from surfaces. This method is precise, efficient, and environmentally friendly. In the manufacturing sector, laser cleaning excels at rust and paint removal. It helps prepare metal surfaces for welding or painting, leading to better adhesion and durability.

In the art restoration field, laser cleaners assist in preserving delicate artifacts. They remove grime without damaging the underlying materials. This precision is crucial for maintaining historical integrity. Similarly, in the automotive industry, laser cleaning aids in preparing engines and components for maintenance. The method wipes away old lubricants and dirt effortlessly.

Despite its advantages, there are challenges. Training operators is essential for safe use. Also, some surfaces may require trial and error for effective cleaning. Not all contaminants are easy to remove. Reflection on these aspects can help optimize the use of laser cleaning technology, ensuring it meets industry-specific needs.

Cost-Effectiveness and Efficiency of Laser Cleaning

Laser cleaning machines offer remarkable cost-effectiveness and efficiency for various applications. Unlike traditional methods, they require less maintenance. The initial investment might be higher, but long-term savings are evident. Reduction in labor costs is a significant benefit, as machines can operate autonomously. This means fewer workers are required for tasks like rust removal or paint stripping.

Additionally, the efficiency of laser cleaning is noteworthy. Laser beams can precisely target contaminants without damaging the underlying material. This precision minimizes waste and reduces the need for costly repairs. However, the technology is not without flaws. Some industries may find initial training challenging. Understanding laser parameters can take time.

Environmental benefits also stand out. Using lasers typically reduces chemical usage, which is great for sustainability. However, the energy consumption of high-powered lasers should not be overlooked. It raises questions about overall environmental impact. Finding a balance is crucial as laser technology continues to evolve. Embracing innovation involves continuously evaluating both benefits and concerns.

Benefits of Using a Laser Cleaner Machine

The chart below illustrates the various benefits of using a laser cleaner machine in terms of cost-effectiveness and efficiency compared to traditional cleaning methods. The data shows the percentage of effectiveness and cost savings over a year for different cleaning solutions.

Safety Considerations and Best Practices in Laser Cleaning

When using a laser cleaner machine, safety is paramount. Operators must wear appropriate protective gear. This includes safety goggles, gloves, and ear protection. The intensity of the laser can cause serious harm. Proper training in handling the equipment is essential. Untrained personnel should never operate the machine.

Understanding the potential hazards helps prevent accidents. Always maintain a safe distance from the laser beam. This can often be overlooked during operation. Additionally, keep the workspace well-ventilated. Toxic fumes may be released during the cleaning process. Employing a fume extraction system can mitigate these risks.

Regular maintenance of the equipment is crucial. This ensures it operates efficiently and safely. Operators should be aware of warning signs of malfunction. Ignoring these can lead to unsafe working conditions. Also, clear communication within the team is necessary. It can help address issues as they arise. Misunderstanding could lead to mistakes and accidents on site.

Maximizing Efficiency: Insights from Industry Reports on Fiber Laser Cleaning Machines for Optimal Metal Paint and Oil Removal Solutions

The advancement of laser cleaning technology has significantly enhanced the efficiency of metal paint and oil removal, providing a more environmentally friendly alternative to traditional cleaning methods. With laser cleaning machines, users benefit from precise positioning and superior cleaning effectiveness, which ensures that even the most challenging contaminants can be eradicated without the risk of damaging the substrate surface. This non-contact approach is not only gentle on materials but also reduces the environmental impact commonly associated with chemical cleaning solutions.

A noteworthy innovation in this sector is the development of portable laser cleaning machines, which address the practical challenges of mobility and convenience faced by users in various industries. These new-generation devices combine powerful cleaning capabilities with the benefit of easy transport, allowing operators to tackle cleaning tasks in diverse locations without compromising on efficiency. By streamlining the cleaning process, these advanced machines promise to optimize operations and minimize downtime, thereby enhancing overall productivity in metalworking and related fields.

FAQS

: The products aim to enhance user experiences and improve daily routines. They often focus on comfort and efficiency.

Generally, yes. However, certain products may have age recommendations. Always check before making a purchase.

Regular cleaning is essential. Follow the care instructions provided. Neglecting maintenance can affect product longevity.

Returns are usually allowed within a specific timeframe. However, terms may vary. Always review the return policy.

New products are developed regularly. Keep an eye out for updates. Interest in specific items often sparks future designs.

Report any damage immediately. Most companies will offer replacements or refunds for damaged items.

Yes, some products utilize sustainable materials. This information is usually highlighted in product descriptions.

Customer support is often available. Don't hesitate to reach out for assistance with setup or troubleshooting.

Customer feedback is crucial. It helps improve products and services, although not every suggestion may be implemented.

Many products include warranties. Terms vary, so check the details carefully to understand the coverage offered.

Conclusion

Laser Cleaner Machines are innovative tools that utilize advanced laser technology to effectively clean surfaces by removing contaminants such as rust, paint, and dirt. The operation of these machines is based on the principle of focused laser beams that interact with pollutants, breaking them down without damaging the underlying material. Compared to traditional cleaning methods, laser cleaning offers several advantages, including reduced chemical use, less waste generation, and the ability to reach complex geometries.

In addition to being environmentally friendly, the applications of Laser Cleaner Machines span various industries, from manufacturing to restoration. They provide a cost-effective and efficient solution for cleaning tasks, with a focus on maximizing productivity. However, while using these machines, safety considerations are paramount, necessitating adherence to best practices to ensure operator safety and optimal results. Overall, the integration of laser cleaning technology marks a significant advancement in surface preparation and maintenance.

Related Posts

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

Innovative Applications of Laser Cleaner Machines in Industrial Maintenance

-

5 Reasons Why the Portable Pulse Laser Cleaner is Essential for Modern Manufacturing

-

5 Essential Tips for Optimizing Your Laser Cleaning Head Rack Performance

-

Discover the Finest Laser Cleaner: Premium Quality from China's Leading Manufacturing Factory

Blog Tags:

Ethan

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top