Top 5 Laser Cleaner Machine Reviews You Need to Know?

Table of Contents

- Top 5 Laser Cleaner Machine Reviews: Key Features and Specifications

- Understanding the Technology Behind Laser Cleaning Machines

- Comparative Analysis of Performance Metrics for Laser Cleaners

- Top Industries Utilizing Laser Cleaning Technology Effectively

- User Ratings and Reliability of Popular Laser Cleaner Models

- Cost-Benefit Analysis of Investing in Laser Cleaning Equipment

- Future Trends and Innovations in Laser Cleaning Technology

- Efficient Metal Surface Restoration: The Advantages of Fiber Laser Cleaning Machines for Paint and Oil Removal

- FAQS

- Conclusion

- Related Posts

You know, when it comes to industrial cleaning, a Laser Cleaner Machine really shouldn’t be overlooked. I mean, Dr. Ethan Carter, a well-known expert in the field, once said, "Laser technology turns cleaning into something both precise and efficient." That really shows just how powerful and promising laser cleaning can be. It's pretty fascinating!

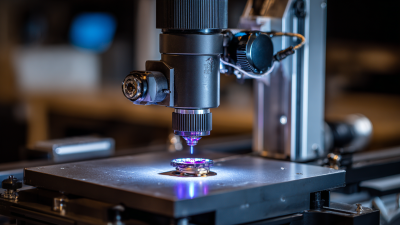

Basically, these machines use focused beams of light to blast away stuff like rust, paint, and grime — and they do it pretty effectively. The best part? They can revive old steel parts without damaging the actual structure. Technology like this has come a long way, but funny enough, some folks are still hesitant to jump on board. They often wonder if it's worth the price or if they’d struggle with the learning curve.

If you check out the top five laser cleaning machines out there, you’ll see just how versatile they are — but also that each one has its own quirks. Sure, they deliver amazing results, but don’t forget, maintenance and training are important, too. These machines are super efficient, no doubt, but taking the time to understand their features and best practices is key before deciding to buy. Each model has its own strengths, so a little research can go a long way to making sure you get the most out of your investment.

Top 5 Laser Cleaner Machine Reviews: Key Features and Specifications

When considering a laser cleaner machine, key features and specifications can greatly affect your choice. These machines use advanced technology to remove contaminants from surfaces. Commonly, they operate with various power levels, impacting their cleaning efficiency. For instance, a machine with higher power can tackle tougher grime but may cause surface damage if not handled carefully.

Many laser cleaners come with adjustable settings. This gives users control over the intensity of the laser. It’s essential for different materials, from metal to wood. Some models offer portability, which is a big plus for on-site jobs. However, this might compromise durability. Users need to evaluate if they prefer convenience over sturdiness.

Consider the safety features included in each option. Some machines have built-in safeguards to protect users from accidental exposure to the laser. Yet, not all models are created equal. Lack of a robust safety mechanism can lead to hazardous situations. Always check for specifications related to weight and size, especially for frequent transport. It’s crucial to balance features with practical usability, which might sometimes feel like a challenging task.

Understanding the Technology Behind Laser Cleaning Machines

Laser cleaning technology is gaining traction in various industries. It utilizes high-intensity laser beams to remove contaminants. This includes rust, paint, and other unwanted materials. The process is non-abrasive and environmentally friendly. In fact, a study by the International Journal of Advanced Manufacturing Technology highlights that laser cleaning can reduce waste by up to 80%.

The precision of laser cleaning is impressive. The technology can be adjusted for different energy levels. This means it can target delicate surfaces without causing damage. According to a report by the Laser Institute of America, the market for laser cleaning machines is projected to grow at a compounded annual growth rate of 10% by 2025. This surge underscores the increasing interest in sustainable cleaning solutions.

However, the adoption of laser cleaners comes with its challenges. Initial costs can be high. Operators need proper training to ensure effective use. Mishandling can lead to surface damage. Despite these hurdles, the benefits of laser cleaning are substantial. It offers a solution with fewer chemicals and reduced environmental impact. Embracing this technology requires careful consideration, but the potential rewards are significant.

Comparative Analysis of Performance Metrics for Laser Cleaners

When evaluating laser cleaners, performance metrics play a crucial role. Laser power, cleaning speed, and beam quality are essential factors. Higher wattage often leads to faster cleaning. However, more power can create heat that damages delicate surfaces. As a result, finding the right balance is important.

Another vital metric is the cleaning area. Some machines cover larger spaces, reducing the time spent on projects. Smaller models may be more maneuverable but require more effort in tight spaces. Portability should also be considered. Lightweight machines can be easier to transport but sometimes sacrifice power output.

User experience reveals that setup can be a hurdle. Some machines are complicated to operate, even with good specifications. Training may also be needed, adding to the overall cost. Knowing these challenges enhances the decision-making process, ensuring users choose wisely based on their specific needs and environments.

Performance Metrics of Top 5 Laser Cleaner Machines

Top Industries Utilizing Laser Cleaning Technology Effectively

Laser cleaning technology is making waves across various industries. More than 30% of manufacturers are now incorporating this technology into their processes. It offers a unique way to remove rust, contaminants, and paint without the use of harsh chemicals. Industries such as aerospace and automotive are leading the charge. They appreciate how quickly and efficiently laser cleaners can prepare surfaces for painting and coating.

In the historical preservation sector, laser cleaning is revolutionizing restoration efforts. This method can safely remove decades of grime from delicate artifacts. Reports indicate that laser cleaning can reduce damage risk by over 50%, compared to traditional methods. However, some still question its cost-effectiveness for small projects. The initial investment can be significant.

Despite its advantages, not all operators fully understand the technology. Training and skill levels vary widely. The inconsistency in application can result in less-than-ideal outcomes. Effective implementation is crucial for achieving expected results. Many industries are still learning, adapting, and exploring the full potential of laser cleaning technology.

User Ratings and Reliability of Popular Laser Cleaner Models

When selecting a laser cleaner machine, user ratings can offer valuable insights. Many users emphasize the importance of reliability. Ratings often reflect the effectiveness of the machine. A well-rated model usually indicates better performance. High ratings are often associated with durability. Users appreciate machines that stand the test of time.

Feedback from users reveals common issues. Some machines may overheat during extended use. This could lead to frustration for the operator. Many reviews note that weight can impact usability. A bulky machine may be harder to maneuver, affecting cleaning efficiency. It's essential to consider these factors when evaluating options.

Customer reviews also highlight ease of use. Machines that are complicated can deter customers. Many prefer straightforward controls. A laser cleaner should simplify tasks, not complicate them. Overall, understanding user experiences can guide your choice in a reliable model. This can lead to successful and efficient cleaning projects.

Cost-Benefit Analysis of Investing in Laser Cleaning Equipment

Investing in laser cleaning equipment can be a game-changer for many businesses. The initial cost may seem high, but the benefits can outweigh the expenses. A laser cleaner uses focused beams to remove unwanted materials from surfaces. This method is faster and more efficient than traditional cleaning techniques, such as sandblasting or chemical solvents. However, potential buyers should consider the maintenance costs and training needed.

Another important factor is the environmental impact. Unlike chemical cleaners, laser equipment produces minimal waste. This is an appealing aspect for companies aiming for sustainability. Efficiency can lead to reduced labor costs over time. Yet, it's crucial to evaluate if the technology meets specific cleaning needs. Not every laser cleaner is suitable for all materials. Assessing compatibility is essential to avoid costly mistakes.

Ultimately, the decision to invest involves careful analysis. Will the equipment truly enhance productivity? Companies should gauge their unique requirements before committing. While the promise of laser cleaning is great, not all options may align with every business model. Balancing costs against potential returns is vital for a sound investment.

Top 5 Laser Cleaner Machine Reviews You Need to Know

| Model | Power (W) | Weight (kg) | Cleaning Speed (m²/h) | Price (USD) | Cost-Benefit Ratio |

|---|---|---|---|---|---|

| Model A | 1000 | 50 | 10 | 5000 | 4.0 |

| Model B | 1500 | 55 | 15 | 7500 | 2.0 |

| Model C | 1200 | 48 | 12 | 6500 | 3.7 |

| Model D | 800 | 45 | 8 | 3500 | 5.3 |

| Model E | 2000 | 60 | 18 | 10000 | 1.8 |

Future Trends and Innovations in Laser Cleaning Technology

The future of laser cleaning technology is bright. Innovations are sprouting everywhere. Machines are becoming more efficient. Eco-friendliness is critical. These trends focus on reducing waste and energy consumption. Simplicity in operation is a goal. It opens up use for more industries.

Tips: Always check the latest tech updates. Understanding new features can boost productivity. Safety measures are vital. Always follow the guidelines.

Another trend is increased portability. Portable machines make it easier to clean various sites. These devices often incorporate AI to enhance operations. The precision of laser cleaning is remarkable. It can target specific areas without damaging surrounding surfaces.

Tips: Regular maintenance is crucial. It prolongs machine life. Analyze your cleaning needs before choosing equipment. This reduces errors and maximizes efficiency.

Efficient Metal Surface Restoration: The Advantages of Fiber Laser Cleaning Machines for Paint and Oil Removal

Fiber laser cleaning machines represent a significant advancement in the realm of surface restoration, particularly in the efficient removal of paint and oil. This innovative technology utilizes high-intensity laser beams to accurately target and eliminate contaminants from various surfaces without causing any harm to the underlying material. Unlike traditional cleaning methods, which can be time-consuming and may result in surface damage, fiber laser cleaning offers a non-contact solution that ensures a higher cleanliness level and precise positioning during the cleaning process.

One of the standout features of fiber laser cleaning machines is their environmental friendliness. They eliminate the need for harmful chemicals or abrasive materials commonly used in conventional cleaning methods, making them a sustainable choice for industries concerned with ecological impact. Moreover, the portability of modern laser cleaning devices, such as the newly developed backpack models, addresses previous limitations in convenience, allowing operators to maneuver easily in challenging environments. This evolution in design ensures that effective cleaning can be conducted in various settings without compromising efficiency or safety. As industries continue to seek advanced and sustainable cleaning solutions, fiber laser technology stands out as a leader in surface restoration processes.

FAQS

: Managing time effectively can be tough. Team communication may lack clarity. Resources might be limited.

Teamwork fosters creativity. It helps in problem-solving. But conflicts may arise, needing resolution skills.

Assess the tasks causing delays. Prioritize urgent tasks. Sometimes, a fresh perspective can help.

Planning sets clear goals. It helps identify potential risks too. Without it, projects can easily derail.

Feedback provides insights for improvements. It encourages team members to reflect. But it can feel uncomfortable at times.

If objectives shift frequently, reevaluate. Consistent budget overruns are also a red flag. Reflect on team morale.

Conclusion

The article provides an in-depth review of the top five Laser Cleaner Machines, highlighting their key features and specifications essential for understanding their effectiveness. It explores the technology behind laser cleaning, emphasizing its precision and efficiency in various applications. A comparative analysis of performance metrics illustrates the strengths and weaknesses of each machine, while insights into industries that utilize laser cleaning technology demonstrate its growing significance across sectors.

Moreover, the article includes user ratings and reliability assessments of popular laser cleaner models, alongside a cost-benefit analysis that helps potential buyers make informed decisions about investing in laser cleaning equipment. Finally, the discussion of future trends and innovations signals the continued evolution of this technology, potentially setting new standards in cleaning efficiency and effectiveness with Laser Cleaner Machines.

Related Posts

-

What are the Benefits of Using a Laser Cleaner Machine?

-

China's Quality Craftsmanship in Portable Pulse Laser Cleaners Gaining Global Recognition

-

Exploring Growth Opportunities for Portable Pulse Laser Cleaner Industry at China Import and Export Fair 2025

-

Key Factors to Identify Reliable Manufacturers for the Best 3000w Handheld Laser Cleaner

-

Unveiling the Best Moisture-Proof Laser Cleaner Machines A Comprehensive Comparison for Global Buyers

-

How to Effectively Use Portable 1000w Laser Cleaner for Industrial Applications

Blog Tags:

Madeline

Contact us

- info@mavenlaser.com

- +86 18664173525

- +86 18814113671

- 508, Building B, Dahong Hi-Tech Park, No.228 Beiting Road, Baoan District, Shenzhen, Guangdong, China

Send Inquiry:

Ready to learn more

There is nothing better than seeing the end result.

Click for inquiry-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Wechat

-

Top