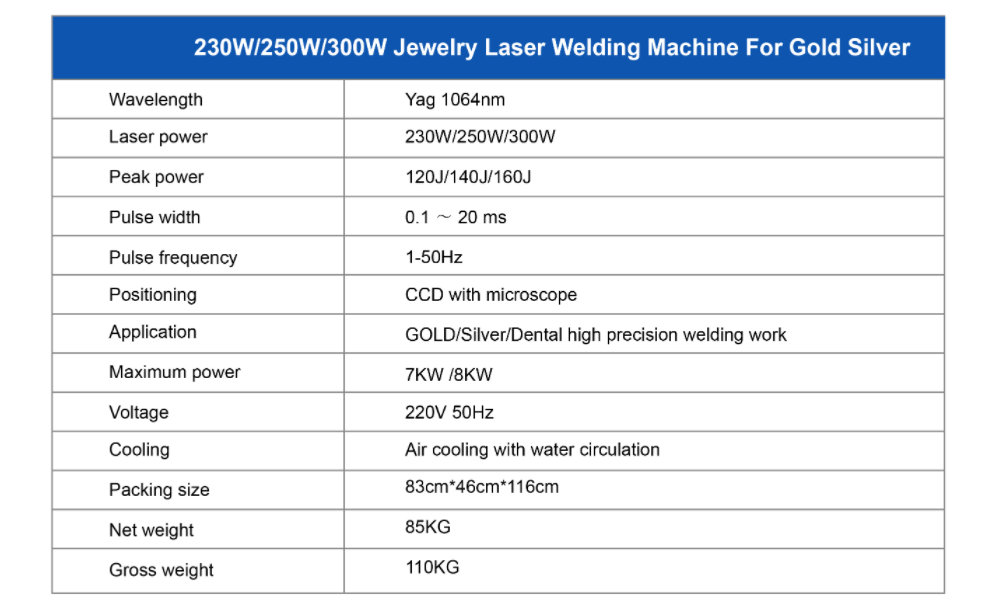

High Precision Necklace Ring Repair Jewelry Setting Gold Sliver Jewelry Laser Spot Welding Machine

Precision Jewelry Spot Welder: Crafting Jewelry Artistry with Micron-Level Accuracy

In the core processes of jewelry manufacturing, spot welding is a critical link that determines the detailed texture, structural stability, and design restoration of jewelry. Especially for precious metal materials such as gold, K-gold, silver, and platinum, traditional welding methods are prone to obvious weld marks, material loss, and insufficient precision, which are difficult to meet the technical requirements of high-end jewelry. Our independently developed precision jewelry spot welder is customized specifically for segmented jewelry scenarios. Integrating micro-spot welding technology, intelligent control, and precious metal-compatible design, it precisely addresses the welding challenges of small welds, microstructures, and high precision. Covering the entire process needs such as chain link splicing, claw setting reinforcement, detailed repair, and special-shaped structure spot welding, it has become a core process equipment for jewelry factories, custom studios, and high-end repair shops.

I. Core Advantages

- Micron-level precise spot welding, restoring design texture without traces

- Full compatibility with precious metals, meeting diverse process requirements

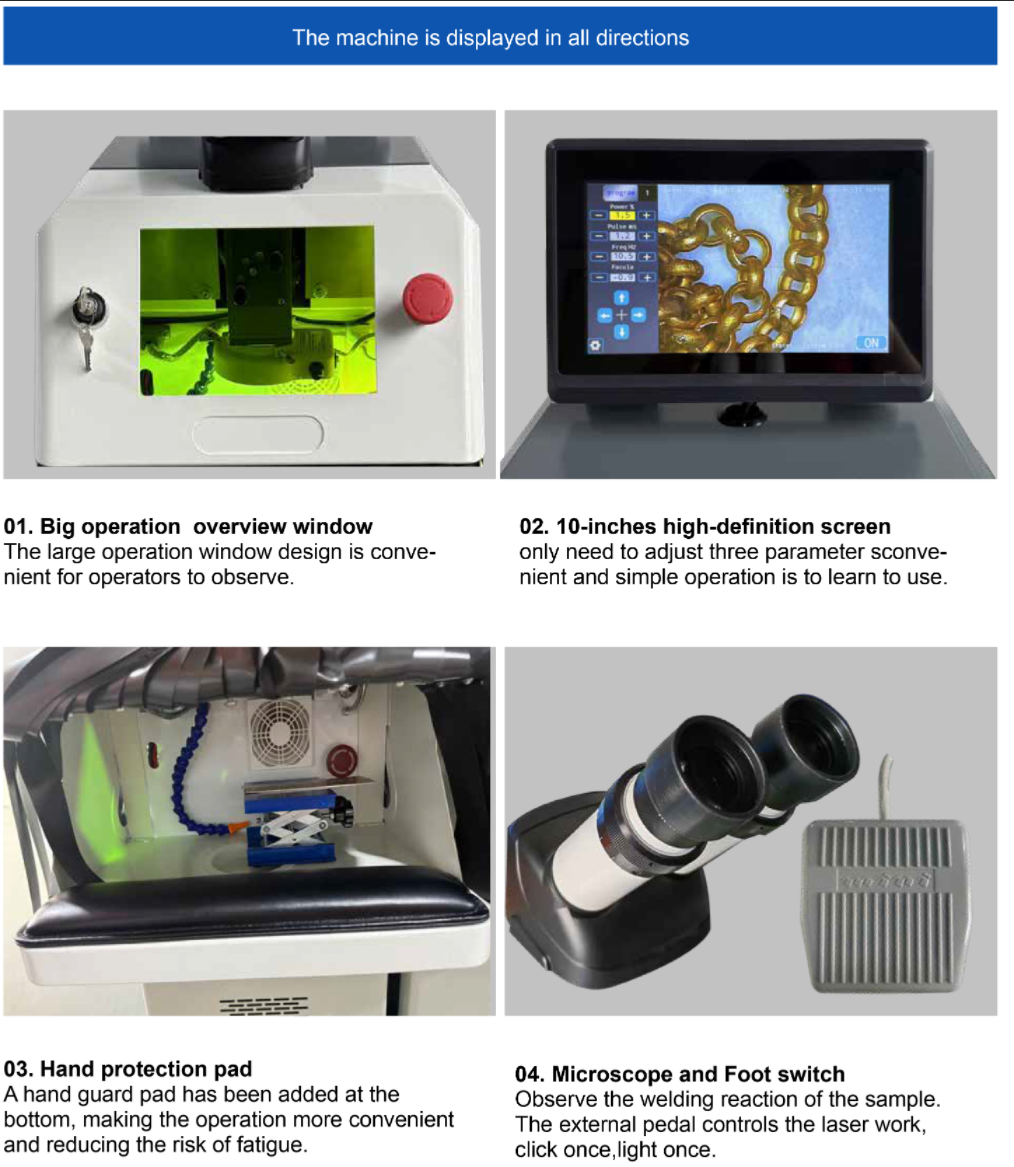

- Intelligent operation, enabling beginners to master precise welding easily

- Material-safe & operator-protective, safeguarding the value of precious metals and operational safety

- Compact and flexible, adapting to diverse production scenarios

III. Application Scenarios: Comprehensive Coverage of the Entire Jewelry Processing Chain

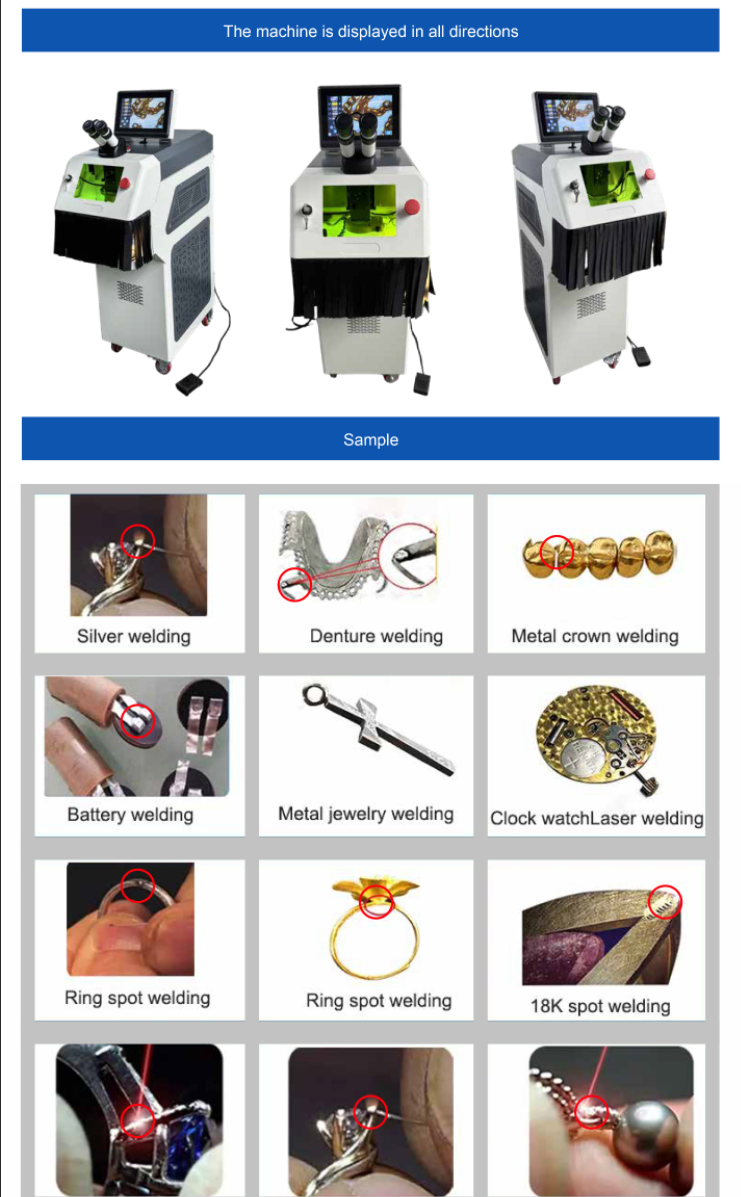

- Batch production in jewelry factories: Chain link splicing spot welding, claw setting/channel setting reinforcement, spot welding of jewelry main structures, connection of special-shaped components. Suitable for batch production of necklaces, bracelets, earrings, etc.;

- High-end custom studios: Detailed spot welding of personalized jewelry, welding of special-shaped structures for niche designs, precise process restoration of customer-exclusive styles;

- Jewelry repair and renovation: Repair of broken chain links, reinforcement of loose claw settings, touch-up welding of old jewelry welds, spot welding for the renovation of precious metal jewelry;

- Jewelry colleges and R&D institutions: New process testing, micro-spot welding technology teaching, R&D verification of high-end jewelry craftsmanship.

Write your message here and send it to us