Multi-functional Jewelry Chain Link Hardware Kitchen & Bathroom Auto Body Panel Welding Handled Laser Welding Machine

Core Components & Working Principles

Basic Structure

Composed of a fiber laser, handheld welding torch, control system, cooling system (water-cooled/air-cooled), optional wire feeder, and safety protection components. Featuring an integrated cabinet design, the handheld welding torch connects to the main unit via a 5–10m optical fiber, enabling flexible adaptation to different workstations.

Working Principle

After focusing, the laser beam achieves extremely high energy density. When irradiated onto the metal surface, it rapidly melts localized areas to form weld seams. This non-contact operation requires no pressure application, resulting in a small heat-affected zone, and the weld strength can meet or exceed that of the base metal.

Mainstream Configurations

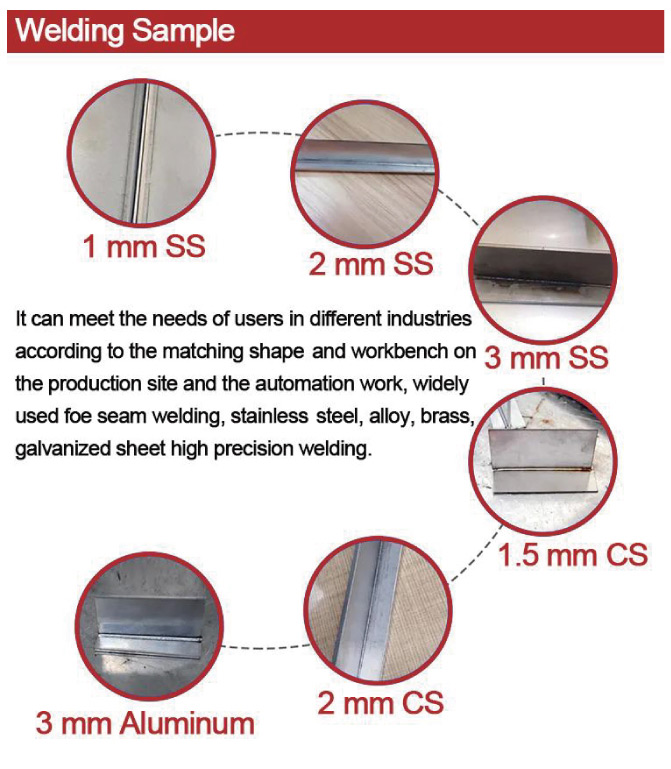

Available in power ranges from 800–3000W, supporting both continuous and pulsed modes. Suitable for heat conduction welding of thin plates and deep penetration welding of medium-thick plates. Some models integrate multi-functional capabilities including welding, cutting, and cleaning, offering enhanced expandability.

Typical Application Scenarios

- General Manufacturing: Hardware, kitchen and bathroom fixtures, door/window railings, shelves, and distribution boxes. Ideal for small-batch, multi-specification welding and on-site installation.

- Automotive & Accessories: Repair welding for auto body panels, pipelines, and battery modules. Suitable for complex structures and high-precision requirements.

- Jewelry: Welding of small components (such as chain links and settings) with minimal, smooth weld spots that prevent damage to precious metals and gemstones.

- Home Appliances & Furniture: Stainless steel kitchenware and furniture metal parts. Improves appearance consistency and production efficiency.

- Maintenance Services: On-site equipment emergency repair, mold mending, and after-sales maintenance of large components. Reduces disassembly, assembly, and transportation costs.

Write your message here and send it to us