【Laser Welding Machine】: A Brilliant Star in Modern Manufacturing

Jewelry laser welding machines are mainly used for hole filling, spot welding of sand holes, and repair welding of gold and silver jewelry. They adopt laser cladding welding technology, which utilizes the high thermal energy of lasers and focused point welding. The surface heat diffuses inward through conduction, and by controlling parameters such as the width, energy, peak power, and repetition frequency of laser pulses, the workpiece is melted to form a specific molten pool. Due to their unique advantages, they have been successfully applied in the processing of gold and silver jewelry as well as the welding of micro and small parts.

Laser processing technology is transforming the development pattern of the jewelry industry with its advantages of high precision, excellent processing quality, personalized design capabilities, and efficiency. Currently, laser technology is widely used in jewelry studios, high-end jewelry enterprises, dental laboratories, watch and glasses workshops, and art design centers. The laser processing equipment of Electromechanical has excellent material and scenario adaptability. It not only supports the fine processing of various metal materials such as gold, silver, platinum, titanium, copper, and stainless steel but also easily handles non-metallic materials like agate, sapphire, redwood, acrylic, and leather.

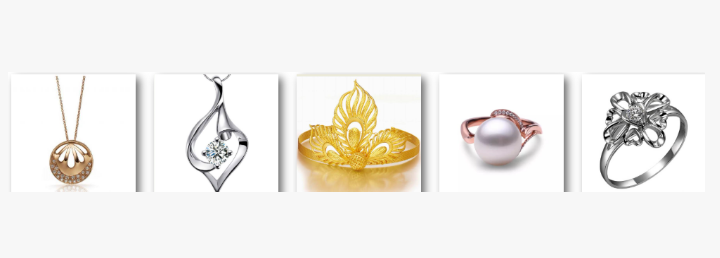

The annual sales volume of China’s jewelry industry has reached approximately 1 trillion yuan (national statistical data is around 650 billion yuan). The per capita number of jewelry pieces has increased from 1 piece 10 years ago to more than 5 pieces, and in some individual cases, it has reached dozens of pieces. This fully demonstrates people’s preference for jewelry.

As high-value products, jewelry is loved by a large number of consumers. Everyone hopes that their jewelry is the most beautiful. However, in many cases, damage often occurs due to careless wearing—for example, the chain breaks, the pendant comes unglued, or the inlaid gemstone falls off. A beautiful product then becomes imperfect, which is always quite annoying to think about. Currently, there are many jewelry repair services in the industry, which have solved urgent problems for consumers.

With the advancement of technology, the jewelry repair industry has undergone significant changes. It has gradually evolved from manual repair to semi-mechanized repair, and then to technologically advanced repair. For instance, the emergence of laser marking machines and welding machines has transformed jewelry repair. Not only do repaired products look as good as new, but they also allow the integration of customized cultural connotations into the jewelry itself.

For a long time, most jewelry repair in the industry has used argon arc welding. Du e to the large size of the welding spot, the surface of some welding spots is not smooth and flat. During a conversation with Director Xing, the Technical Director of Technology, they stated that the greatest advantages of laser welding machines are fast speed and smooth and flat welding surfaces, which can effectively solve most problems of traditional welding. During visits and communications with customers, many people also mentioned that when repairing necklaces, the interface often looks unappealing and uneven. They always feel that such items are not suitable to wear outside; yet, it is a pity to put them aside, and wearing them causes internal conflict.

Director Xing also stated that the jewelry laser welding machine adopts German craftsmanship and domestic advanced lasers. It not only has a small light spot but also requires no consumables, effectively solving the problem of harm to the human body caused by the addition of harmful welding flux in products.

Technology is developing, and society is progressing. It is believed that more high-tech products will emerge in the future to make our lives better.

✦ Product Features

- ◆ One-click automatic water pumping: Simplifies operation and enables easy water pumping, providing a more convenient user experience.

- ◆ Intelligent air-cooled stepless speed regulation heat dissipation system: Adopts advanced heat dissipation technology to ensure stable operation of the equipment. The stepless speed regulation design makes heat dissipation more efficient and flexible.

- ◆ Microscope and built-in camera system: Perfectly combined to provide users with a high-definition and detailed observation experience, allowing every detail to be clearly visible.

- ◆ Compact size, space-saving: The compact design is not only easy to carry but also saves space, enabling users to enjoy more possibilities in a limited space.

- ◆ CCD display integrated touch screen: Combines advanced display technology with touch screen operation to provide an intuitive and user-friendly human-machine interface, making operation more effortless and pleasant.

Post time: Sep-25-2025