Application of Laser Precision Spot Welding in the Consumer Electronics Industry

In recent years, as competition in the consumer electronics market has become increasingly fierce, electronic product manufacturers have put forward higher requirements for products. Traditional processing methods are prone to unstable product quality, part melting, difficulty in forming normal weld nuggets, and low yield rates. The emergence of laser processing technology can quickly solve these problems for electronic product manufacturers. In the production of high-end electronic products, laser processing plays a significant role in optimizing product volume and improving quality, making products lighter, thinner, and more stable. It is reported that laser technology (more than 20 different processes) and related manufacturing equipment are used in approximately 70% of electronic product processing and manufacturing links.

Currently, laser precision spot welding is mainly applied to electronic product casings, shielding covers, USB connectors, conductive patches, etc. It has advantages such as small thermal deformation, precise control of the action area and position, high welding quality, ability to achieve dissimilar material welding, and easy automation. However, different welding methods need to be adopted when welding different materials.

Based on the results of numerous experiments, welding engineers have summarized the optimal laser precision spot welding methods for different materials such as highly reflective materials, thin metal sheets, and dissimilar materials in the production and manufacturing of consumer electronics.

1. Laser Precision Spot Welding Method for Highly Reflective Materials

When welding highly reflective materials such as aluminum and copper, different welding waveforms have a significant impact on welding quality. Using a laser waveform with a pre-spike can break through the high reflectivity barrier. The instantaneous high peak power can quickly change the metal surface state, raising its temperature to the melting point, thereby reducing the reflectivity of the metal surface and improving energy utilization. In addition, due to the fast thermal conductivity of materials like copper and aluminum, the use of a slow-decay waveform can optimize the appearance of weld spots.

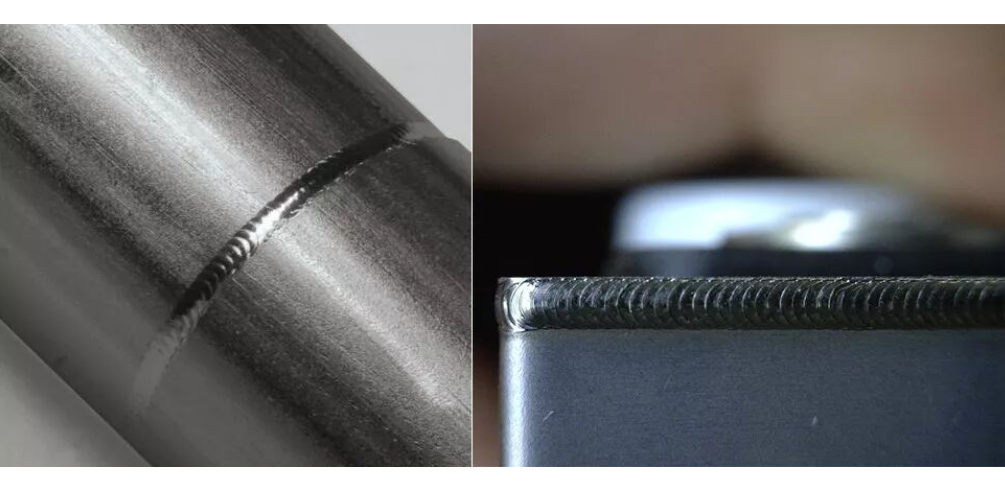

On the other hand, the laser absorption rate of materials such as gold, silver, copper, and steel decreases as the wavelength increases. For copper, when the laser wavelength is 532nm, the absorption rate of copper is close to 40%. A comparative analysis of the characteristics of infrared lasers and green lasers shows that infrared lasers have a larger spot size, shorter focal depth, and lower absorption rate by red copper; green lasers have a smaller spot size, longer focal depth, and higher absorption rate by red copper. When pulse spot welding is performed on red copper using infrared lasers and green lasers respectively, it is found that the size of the weld spots after welding with infrared lasers is inconsistent, while the weld spots formed by green lasers are more uniform in size, consistent in depth, and smooth on the surface (Figures 1-2). Welding with green lasers achieves more stable results, and the required peak power is more than half lower than that of infrared lasers.

2. Laser Precision Spot Welding Method for Thin Metal Sheet Materials

When traditional millisecond lasers are used to weld thin metal sheet materials, the materials are prone to penetration and the weld spots are relatively large. Due to their own instability and low laser absorption rate in the solid state, highly reflective materials often experience spattering, insufficient welding, and other phenomena during welding. To solve the welding difficulties of thin sheets and highly reflective metals, analog and digital modulation are respectively performed on the QCW/CW mode of fiber lasers. A single trigger can realize N pulse outputs, achieving single-point multi-pulse welding with lower power.

3. Laser Precision Spot Welding Method for Dissimilar Materials

When laser welding thin dissimilar materials, problems such as insufficient welding, cracks, and low joint strength are likely to occur. This is because the two materials have large differences in physical properties, low mutual solubility, and are prone to forming brittle intermetallic compounds, which greatly reduce the mechanical properties of the welded joint. Using a nanosecond laser with high beam quality through high-speed scanning can precisely control heat input to inhibit the formation of intermetallic compounds, realize lap welding of thin dissimilar metal sheets, and improve weld formation and mechanical properties.

Common Types of Precision Welding

What are the common types of precision welding? In the field of welding, the common types of precision welding processing mainly include precision resistance welding, laser welding, ultrasonic welding, and micro arc spot welding. Due to the unique characteristics of lasers, compared with other welding processes, precision laser welding processing has the advantages of high efficiency, environmental friendliness, and high processing accuracy.

Main Applications of Laser Precision Spot Welding

Where is laser precision spot welding mainly used? Currently, laser precision spot welding can be used for precision welding of various small and heat-sensitive parts such as jewelry, watch hairsprings, and integrated circuit leads. It is suitable for industries such as optoelectronic devices, electronics, communications, machinery, automobiles, military industry, and gold jewelry. As a type of laser welding, laser precision spot welding is a new welding method. Compared with traditional resistance spot welding, laser precision spot welding has its unique advantages. By using laser as the heat source, spot welding is fast, precise, with low heat input and small workpiece deformation. Lasers have good accessibility, which can reduce positional and structural limitations during spot welding. They do not require a large number of auxiliary equipment, can quickly adapt to product changes, and meet market demands. With the rapid development of China’s economy and the continuous improvement of scientific and technological level, the development of laser precision spot welding technology has achieved rapid progress. Due to its advantages of high welding precision and fast speed, it has been widely used in the processing of thin metal sheet materials.

Advantages of Laser Precision Welding

First, let’s understand the advantages of laser precision welding:

- It can realize welding of various trajectories. Lasers have strong directionality, which also achieves good results for welding irregular materials.

- Firm welding. After focusing, the laser spot is small with high energy density, ensuring that the beam forms a heat source area in a very short time. After melting, cooling, and crystallization, a firm weld seam and spot are formed.

- High welding precision. The distribution of laser energy has temporal and spatial characteristics, allowing the beam to be divided into multiple optical paths for simultaneous processing operations, providing a strong guarantee for welding precision.

- Fast welding speed. Laser technology is combined with computer CNC technology. In terms of key equipment detection and motion control systems, the system integration includes real-time detection and feedback processing, which accelerates the speed of system information processing and improves welding efficiency.

Post time: Nov-13-2025